P-type gate enhanced transistor based on oxidation self-stop technology and preparation method thereof

A self-stopping and enhanced technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems that cannot meet the urgent needs of high frequency, low loss and high power capacity of the power system, and achieve current suppression Collapse, avoid interface states, and improve device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

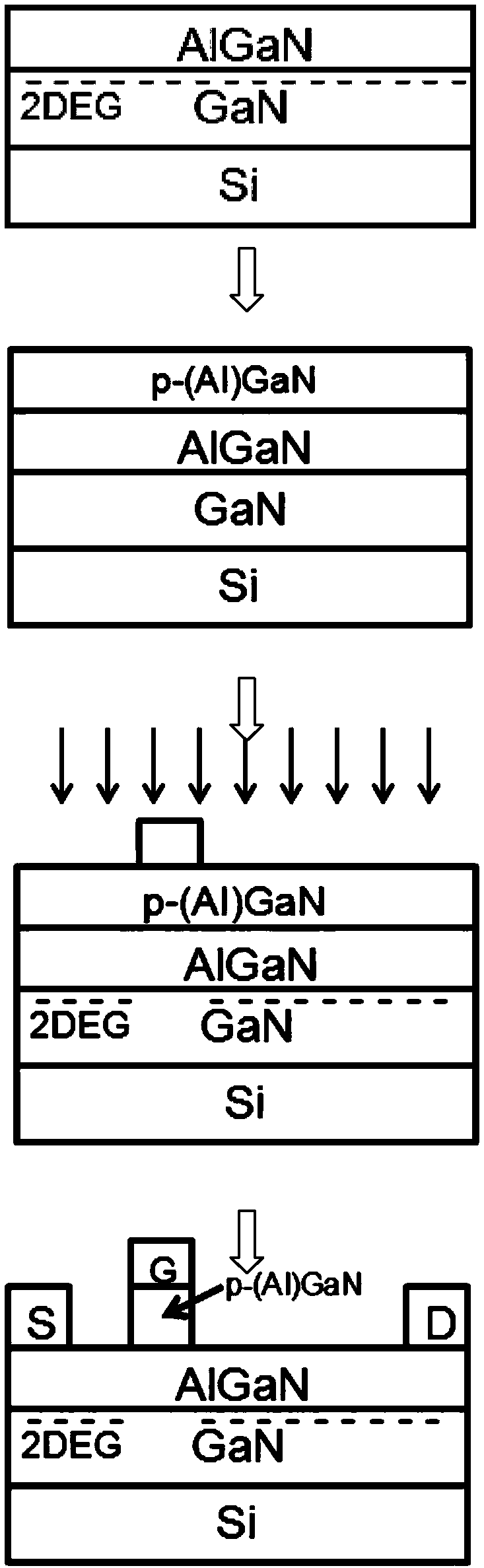

[0039] An embodiment of the present invention provides a method for preparing a p-type gate enhancement transistor based on oxidation self-stop technology, including:

[0040] providing a heterojunction comprising a first semiconductor and a second semiconductor, the second semiconductor being formed on the first semiconductor and having a bandgap wider than that of the first semiconductor, the heterojunction having two-dimensional electrons formed therein gas;

[0041] sequentially growing a third semiconductor and a fourth semiconductor on the heterojunction;

[0042] placing a mask over the fourth semiconductor, and oxidizing the fourth semiconductor exposed from the mask to form an oxide, and self-stopping the oxidation reaction upon reaching the third semiconductor; and

[0043] making the source, drain and gate, so that the gate is connected to the fourth semiconductor remaining in the region under the gate, the source and the drain can be connected through the two-dime...

Embodiment 1

[0079] The preparation method of the p-type gate enhancement transistor based on oxidation self-stop technology provided by the present invention may include the following steps:

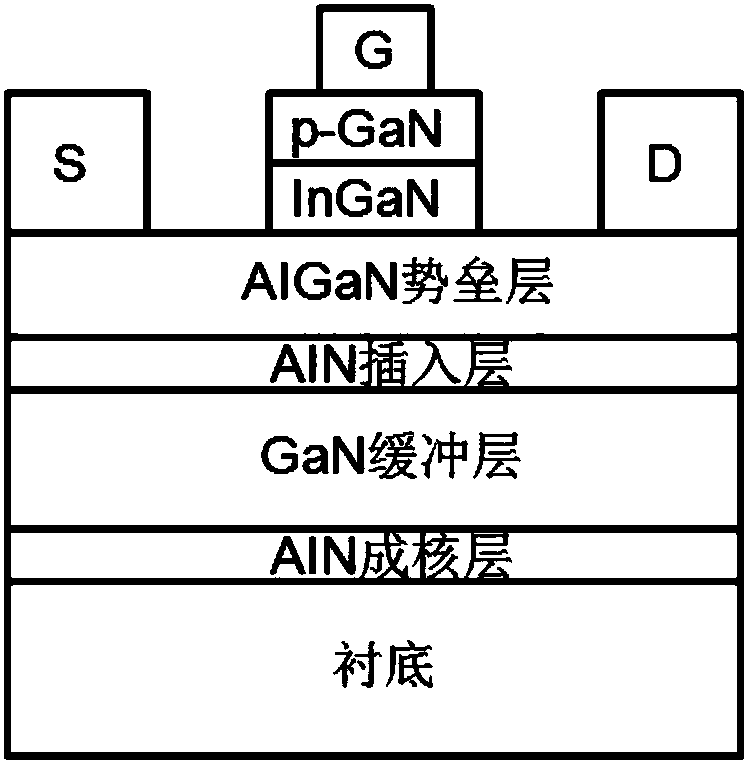

[0080] (1) GaN buffer layer, GaN channel layer ( That is, the first semiconductor), the AlGaN barrier layer (that is, the second semiconductor), and GaN as an oxidation self-stopping layer (that is, the third semiconductor), the structure of which is shown in Figure 6(a), where the GaN channel layer and the AlGaN potential The barrier layer forms a heterojunction, and a two-dimensional electron gas is formed in the heterojunction; then p-AlGaN (that is, the fourth semiconductor) is epitaxially grown on the oxidation self-stop layer GaN, and its structure is shown in Figure 6(b) Show;

[0081] (2) The source, drain region, and gate region on p-AlGaN (that is, the fourth semiconductor) by plasma-enhanced chemical vapor deposition PECVD or low-pressure chemical vapor deposition LPCVD (wherein the sour...

Embodiment 2

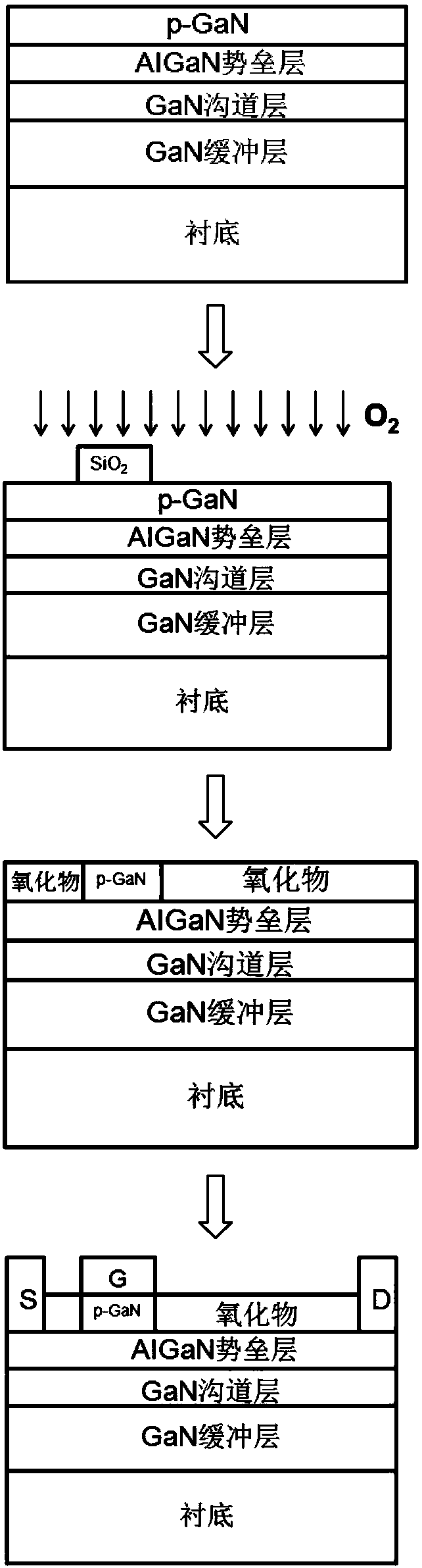

[0088] In this embodiment, the preparation method of the p-type gate enhancement transistor based on oxidation self-stop technology is basically the same as that of Embodiment 1 except for steps (2), (3) and (4). The steps in this embodiment (2): In the gate region of p-AlGaN (that is, the fourth semiconductor) (the material of the fourth semiconductor in this embodiment is p-AlGaN) by plasma-enhanced chemical vapor deposition PECVD or low-pressure chemical vapor deposition LPCVD (where the gate area or the area under the gate refers to the area corresponding to the gate) to grow SiO 2 or Si 3 N 4 Protective layer, the growth area can be determined by techniques such as photolithography and mask transfer, and its structure is as Figure 13 shown;

[0089] Step (3) is: with various oxidation methods such as oxidation method (including dry thermal oxidation, wet thermal oxidation, O plasma, annealing under oxygen-containing atmosphere, oxygen source can be O 2 , O 3 、H 2 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com