Self-contained soldering flux type solder ring and preparation method thereof

A brazing material ring and brazing flux technology, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of flux layer corrosion, slow heat transfer, and reduce brazing reliability, so as to improve oxidation resistance and corrosion resistance, improve fluidity and wettability, and improve soldering reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

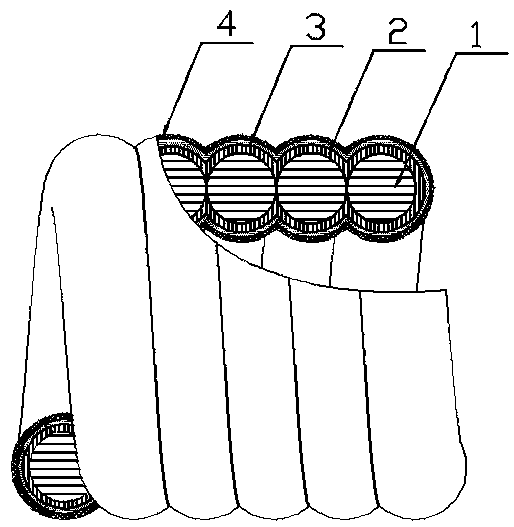

[0030] A self-flux type solder ring, which is composed of a solder inner core 1, a metal coating 2, an intermediate active layer 3 and a moisture-proof outer layer 4, and the metal coating 2 is plated on the outer surface of the solder inner core 1 , the metal coating 2 is a metal tin layer with a thickness of 0.04 mm, the middle active layer 3 is coated on the outside of the metal coating 2, the middle active layer 3 is QJ102 high-activity flux, and the thickness is 0.2 mm, and the moisture-proof outer layer 4 is adhered to Outside the middle active layer 3 , the moisture-proof outer layer 4 is prepared from ethyl α-cyanoacrylate and dimethyl carbonate at a ratio of 1:5, and the thickness is 0.09mm.

[0031] The high-activity flux QJ102 has high activity and film removal ability, strong ability to remove oxide film, and ensures the activity of the flux layer. Its thickness can be 0.09-0.5mm, which greatly reduces the thickness of the flux layer and ensures the welded pipeline ...

Embodiment 2

[0040]A self-flux type solder ring, which is composed of a solder inner core 1, a metal coating 2, an intermediate active layer 3 and a moisture-proof outer layer 4, and the metal coating 2 is plated on the outer surface of the solder inner core 1 , the metal coating 2 is a metal indium layer with a thickness of 0.02 mm, the middle active layer 3 is coated on the outside of the metal coating 2, the middle active layer 3 is QJ102 high-activity flux, and the thickness is 0.5 mm, and the moisture-proof outer layer 4 is adhered to Outside the middle active layer 3, the moisture-proof outer layer 4 is prepared by acrylic resin adhesive and dimethyl carbonate at a ratio of 1:5, with a thickness of 0.2 mm.

[0041] The preparation method of the above-mentioned self-contained flux-type solder ring comprises the following steps:

[0042] a. Make the brazing filler metal into a brazing filler metal ring, then put it into the ultrasonic cleaning equipment, add metal cleaning agent, and d...

Embodiment 3

[0049] A self-flux type solder ring, which is composed of a solder inner core 1, a metal coating 2, an intermediate active layer 3 and a moisture-proof outer layer 4, and the metal coating 2 is plated on the outer surface of the solder inner core 1 , the metal coating 2 is a metal indium layer with a thickness of 0.001 mm, the middle active layer 3 is coated on the outside of the metal coating 2, the middle active layer 3 is QJ102 high-activity flux, and the thickness is 0.09 mm, and the moisture-proof outer layer 4 is adhered to Outside the middle active layer 3 , the moisture-proof outer layer 4 is prepared by acrylic resin adhesive and dimethyl carbonate at a ratio of 1:5, with a thickness of 0.001mm.

[0050] The preparation method of the above-mentioned self-contained flux-type solder ring comprises the following steps:

[0051] a. Make the brazing filler metal into a brazing filler metal ring, then put it into the ultrasonic cleaning equipment, add metal cleaning agent, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com