A method for preparing superfine cuprous oxide with high yield

An ultra-fine cuprous oxide, high-yield technology, applied in the direction of copper oxide/copper hydroxide, etc., can solve the problems of low cuprous oxide yield, harsh system process, and uneasy control, and achieve excellent electrochemical performance, Less environmental pollution, good shape and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Prepare the solution

[0030] Mix anhydrous copper sulfate with water to make 40mL copper sulfate solution with a concentration of 1.0mol / L; mix anhydrous glucose with water to make 40mL glucose solution with a concentration of 0.5mol / L; mix sodium hydroxide with water to make into 20 mL of sodium hydroxide solution with a concentration of 5.3 mol / L.

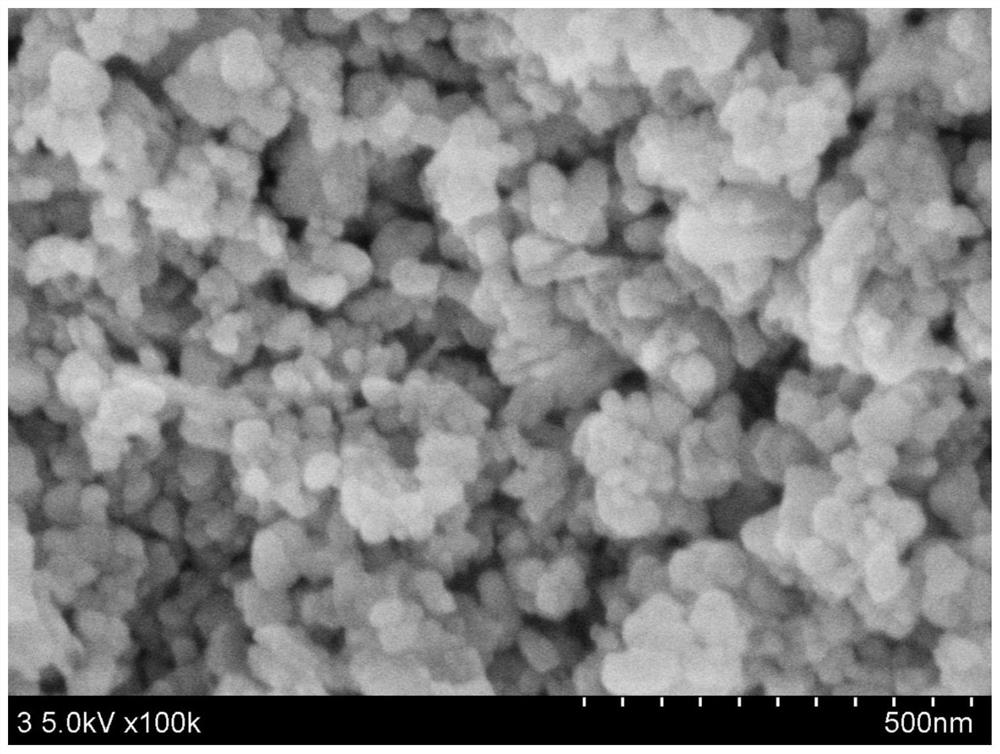

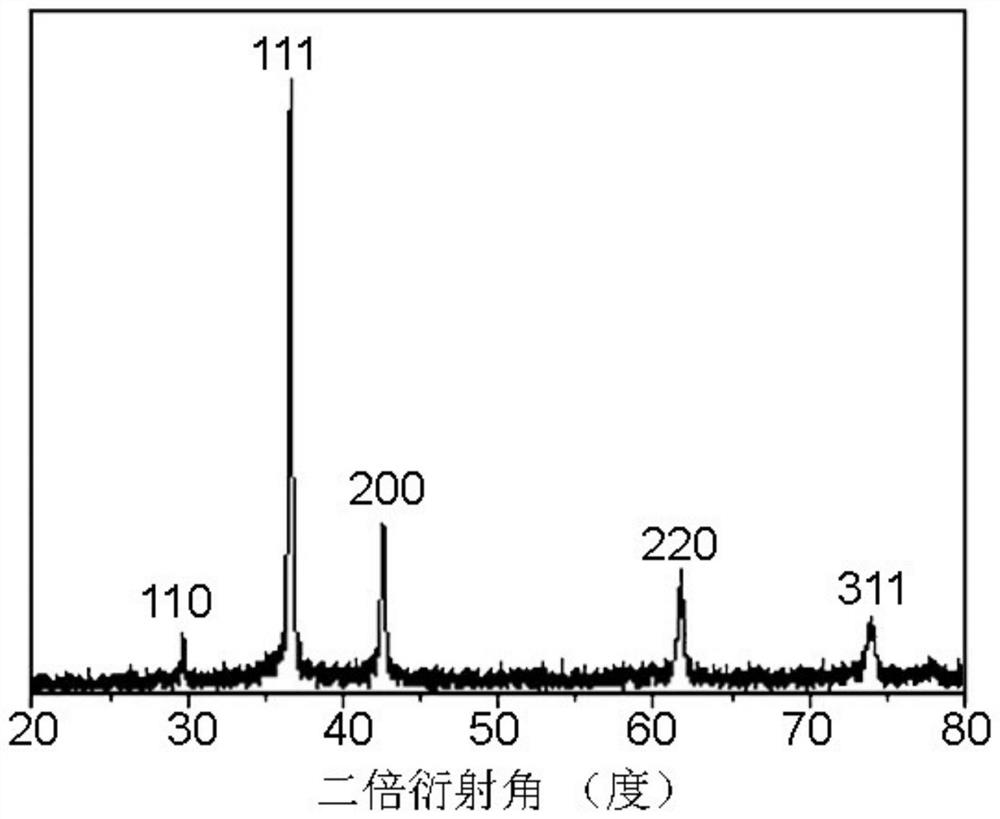

[0031] (2) Preparation of ultrafine cuprous oxide by low temperature method

[0032] At room temperature (20°C), add 40mL of 1.0mol / L copper sulfate solution to 20mL of 5.3mol / L sodium hydroxide solution in the reaction vessel, and stir (540 rpm) while adding to generate copper hydroxide Precipitation; then at room temperature (20°C), add 40mL of 0.5mol / L glucose solution, and stir (540 rpm) while adding, the pH value of the hydrothermal reaction system is about 13.4; then seal the reaction vessel; then use Heat the water bath to 60°C, in a subcritical state, stir (540 rpm) and react for 6 hours, filter 3 times, pla...

Embodiment 2

[0035] (1) Prepare the solution

[0036] Mix anhydrous copper sulfate with water to make 100mL copper sulfate solution with a concentration of 1.1mol / L, mix anhydrous glucose with water to make 100mL glucose solution with a concentration of 0.5mol / L, mix sodium hydroxide with water to make into 50 mL of sodium hydroxide solution with a concentration of 5.2 mol / L.

[0037] (2) Preparation of ultrafine cuprous oxide by low temperature method

[0038] At room temperature (20°C), add 100mL of 1.1mol / L copper sulfate solution to 50mL of 5.2mol / L sodium hydroxide solution in the reaction vessel, and stir (540 rpm) while adding to form copper hydroxide precipitate; Then at room temperature (20°C), add 100mL of 0.5mol / L glucose solution, and stir while adding (540 rpm), the pH value of the hydrothermal reaction system is about 13.3; then seal the reaction vessel; then heat with a water bath To 60°C, under supercritical state, stir (540 rpm) for 6 hours, filter 4 times, and place the...

Embodiment 3

[0040] (1) Prepare the solution

[0041] Mix anhydrous copper sulfate with water to make 400mL copper sulfate solution with a concentration of 1.0mol / L, mix anhydrous glucose with water to make 400mL glucose solution with a concentration of 0.5mol / L, mix sodium hydroxide with water to prepare into 200 mL of sodium hydroxide solution with a concentration of 5.2 mol / L.

[0042] (2) Preparation of ultrafine cuprous oxide by low temperature method

[0043]At room temperature (20°C), add 400mL of 1.0mol / L copper sulfate solution to 200mL of 5.2mol / L sodium hydroxide solution in the reaction vessel, and stir (540 rpm) while adding to form copper hydroxide precipitate; Then at room temperature (20°C), add 400mL of 0.5mol / L glucose solution, and stir while adding (540 rpm), the pH value of the hydrothermal reaction system is about 13.4; then seal the reaction vessel; then heat it with a water bath To 60 ℃, under the subcritical state, stirring (540 rpm) reaction for 6 hours, filtere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com