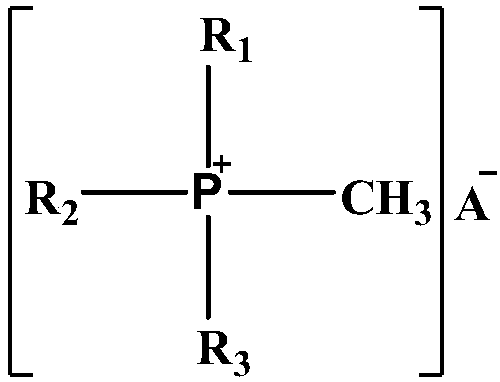

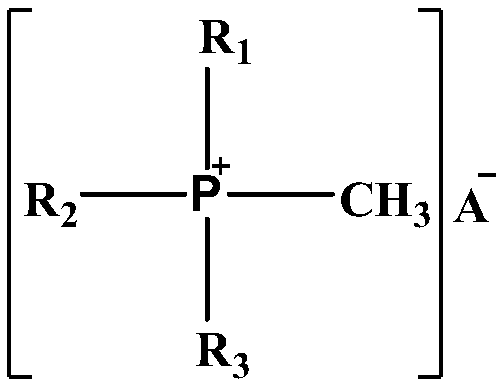

Room-temperature quaternary phosphonium salt ionic liquid and preparation method thereof

A technology of ionic liquid and quaternary phosphonium salt, which is applied in the field of room temperature quaternary phosphonium salt ionic liquid and its preparation, and achieves the effect of avoiding toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

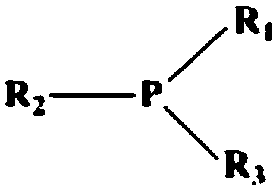

Method used

Image

Examples

Embodiment 1

[0029] Weigh trimethylphosphine (76.1g, 1mol), dimethyl carbonate (270.2g, 3mol), ethyl acetate (34.6g, 10%) and 20%-CuO / Al 2 o 3 Catalyst (1.39g, 0.4%) joins in the stainless steel autoclave, logical N 2 The air in the reactor was replaced, and the temperature was raised to 100° C. for 12 hours of reaction. After the reaction was completed, the temperature was lowered to 70° C. with cooling water, the catalyst was recovered by filtration, and unreacted raw materials and solvents were distilled off under reduced pressure. The product was washed with ethyl acetate, and then vacuum-dried at 60° C. for 5 hours to obtain 141.2 g of tetramethylphosphonium methyl carbonate, with a yield of about 85%. Weigh methylcarbonate quaternary phosphonium salt tetramethylmethylphosphonium carbonate (49.9g, 0.3mol) and dissolve it in acetone (59.9g), add acetic acid (21.6g, 0.36mol), and reflux reaction at 40°C under magnetic stirring 3 hours. After the reaction was completed, the solvent w...

Embodiment 2

[0031] Weigh dodecyldimethylphosphine (230.4g, 1mol), dimethyl carbonate (180.1g, 2mol), ethanol (123.2g, 30%) and 30%-BaCO 3 / ZrO 2 Catalyst (0.41g, 0.1%) joins in the stainless steel autoclave, logical N 2The air in the reactor was replaced, the initial pressure was set to 1.0 MPa, and the temperature was raised to 120° C. to react for 10 hours. After the reaction was completed, the temperature was lowered to 60° C. with cooling water, the catalyst was recovered by filtration, and unreacted raw materials and solvents were distilled off under reduced pressure. Recrystallize with acetone, then vacuum dry at 60° C. for 5 hours to obtain 256.4 g of dodecyltrimethylphosphonium methyl carbonate, and the yield is about 80%. Weigh methyl carbonate quaternary phosphonium salt dodecyl trimethyl methyl phosphonium carbonate (64.1g, 0.2mol) and dissolve in methanol (32.1g), add n-octanoic acid (30.3g, 0.21mol), at 50°C The reaction was refluxed for 2.5 hours under magnetic stirring. ...

Embodiment 3

[0033] Weigh tetradecyl diethylphosphine (143.2g, 0.5mol), dimethyl carbonate (270.2g, 3mol), dichloromethane (82.7g, 20%) and 40%-Mn (OH) 2 / TiO2 catalyst (2.07g, 0.5%) joins in the stainless steel autoclave, logical N 2 The air in the reactor was replaced, the initial pressure was set to 0.2 MPa, and the temperature was raised to 140° C. for 10 hours. After the reaction was completed, the temperature was lowered to 55° C. with cooling water, the catalyst was recovered by filtration, and unreacted raw materials and solvents were distilled off under reduced pressure. The product was washed with dichloromethane, and then vacuum-dried at 60° C. for 5 hours to obtain 173.2 g of tetradecyl diethylmethyl phosphonium methyl carbonate, with a yield of about 92%. Take methyl carbonate quaternary phosphonium salt tetradecyl diethylmethyl phosphonium methyl carbonate (75.3g, 0.2mol) and dissolve in chloroform (113g), add lauric acid (42.1g, 0.21mol), The reaction was refluxed at 60° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com