Fluorosilicone isoprene rubber and preparation method thereof as well as wide-temperature range high-strength aviation tire rubber material and preparation method thereof

A technology of silicon isoprene rubber and rubber material, which is applied in the field of rubber composite materials, can solve the problems of high instantaneous load, high internal pressure of inflation, large heat generation, etc., and achieves the effect of broadening the application range, improving performance, and reducing heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

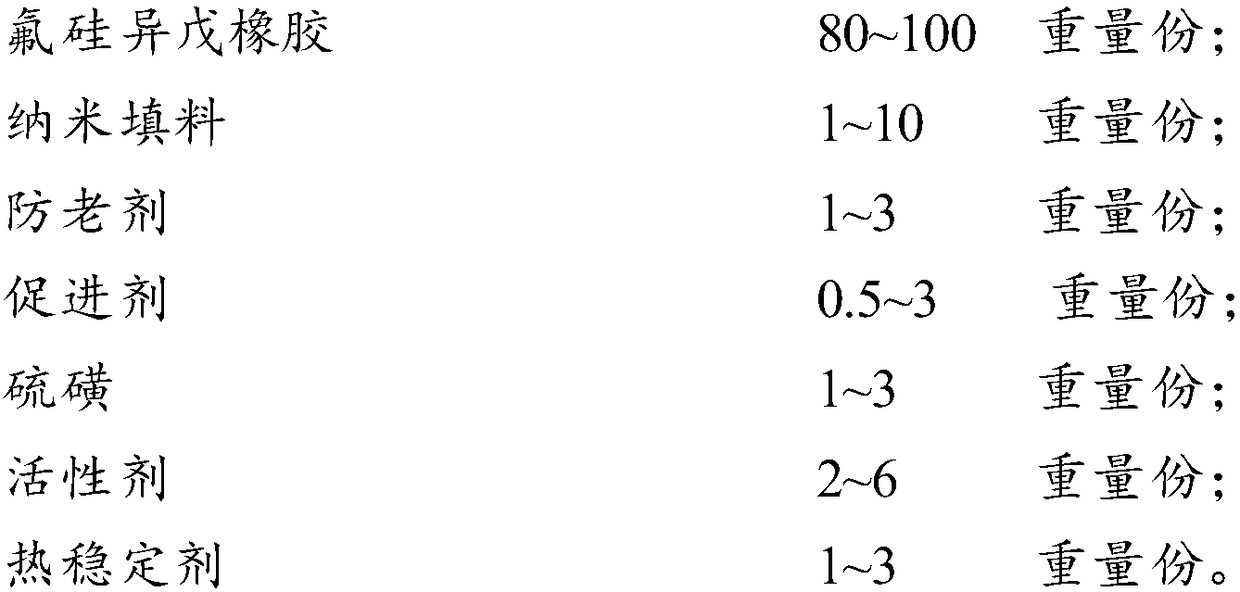

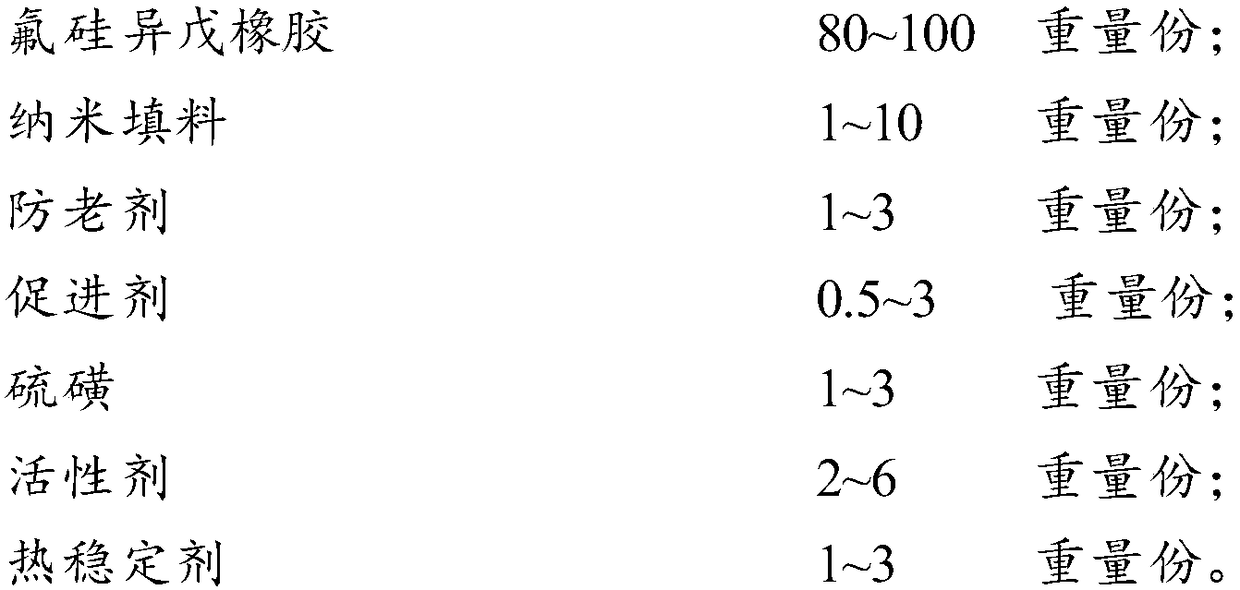

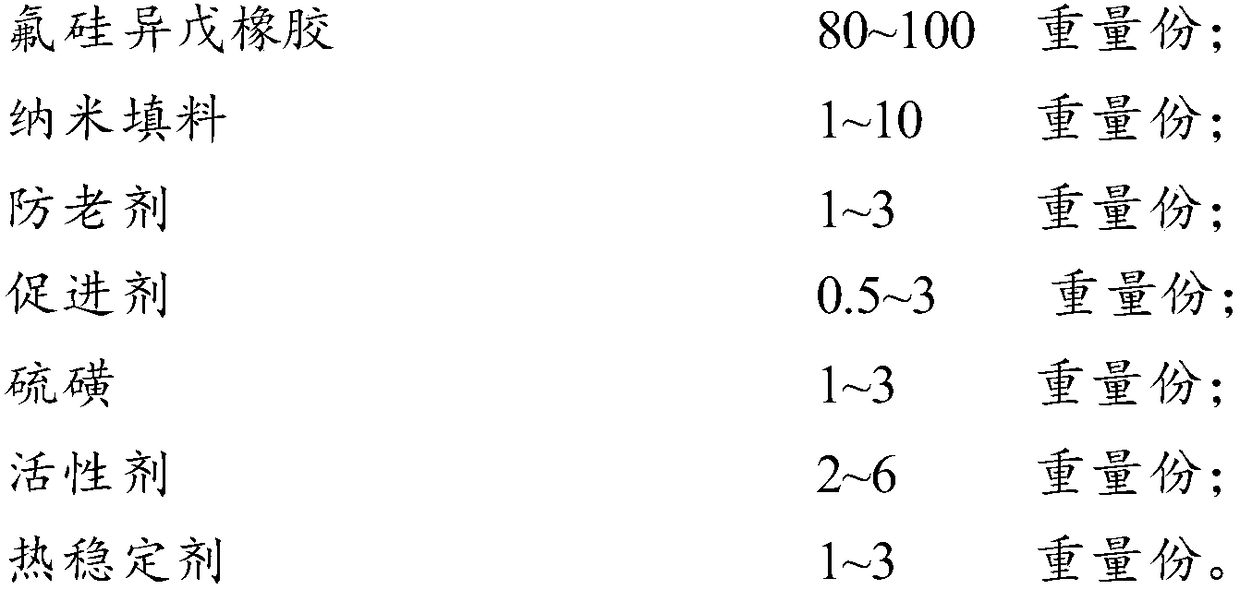

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a preparation method of fluorosilicone isoprene rubber, comprising the following steps:

[0056] 1) Under the action of a metal catalyst, after reacting isoprene, an organoaluminum compound, an organoboron salt and a good solvent, a reaction system is obtained;

[0057] 2) Add fluorine-containing siloxane to the reaction system obtained in the above steps, continue the reaction, stop the reaction, and perform post-treatment to obtain fluorosilicone isoprene rubber.

[0058] In the present invention, the selection, composition and structure of the materials in the above preparation method, as well as the corresponding optimization principles, can preferably correspond to the selection, composition and structure of the materials in the aforementioned fluorosilicone isoprene rubber, and the corresponding optimization principles. No more details here.

[0059] In the invention, firstly, under the action of a metal catalyst, a reaction sy...

Embodiment 1

[0109] (1) prepare fluorosilicone isoprene rubber;

[0110] Add 25μmol rare earth metal catalyst, 10ml toluene, 50μmol AlMe 3 , 5mmol isoprene, 25μmol[Ph 3 C][B(C 6 f 5 ) 4 ], after reacting at 0°C for 24h under constant stirring, add 5mmol trifluoropropylmethylcyclotrisiloxane, continue to react for 24h, add 30mL containing 5% 2,6-di-tert-butyl-4-methylphenol ethanol to stop the reaction; the reaction solution was precipitated with ethanol to precipitate solid matter, and the solid matter was vacuum-dried at 40° C., and the solvent was removed to constant weight to obtain 2.68 g of fluorosilicone isoprene rubber with a conversion rate of 100%. .

[0111] (2) Mixing and vulcanization

[0112] In 150g of fluorosilicone isoprene rubber prepared in step (1), 1.5g of graphene oxide, 1.5g of stearic acid, 1.5g of zinc oxide, 1.5g of heat stabilizer, 1.5g of anti-aging agent, 0.75g of accelerator, Sulfur 1.5g, pressurized at 10MPa, kneaded at 80°C, added each component separa...

Embodiment 2

[0118] (1) prepare fluorosilicone isoprene rubber;

[0119] Add 30μmol rare earth metal catalyst, 15ml toluene, 90μmol AlMe 3 , 10mmol isoprene, 50μmol[Ph 3 C][B(C 6 f 5 ) 4 ], after reacting at 25°C for 48h under constant stirring, add 2mmol trifluoropropylmethylcyclotrisiloxane, continue to react for 48h, add 35mL containing 5% 2,6-di-tert-butyl-4-methylphenol ethanol to stop the reaction; the reaction solution was precipitated with ethanol to precipitate solid matter, and the solid matter was vacuum-dried at 50° C., and the solvent was removed to constant weight to obtain 1.62 g of fluorosilicone isoprene rubber with a conversion rate of 100%. .

[0120] (2) Mixing and vulcanization

[0121] In the fluorosilicone isoprene rubber 100g described in step (1), add graphene oxide 2g, stearic acid 2g, zinc oxide 1g, heat stabilizer 1g, anti-aging agent 1.5g, accelerator 2g, sulfur 2g successively, add Press 13MPa, knead at 100°C, add each component separately, mix for 10 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Acron wear | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com