Phenolic resin aerogel with nanofiber network structure, carbon aerogel material and preparation method of phenolic resin aerogel

A phenolic resin and nanofiber technology is applied in the field of phenolic resin aerogel and carbon aerogel materials and their preparation, which can solve the problems of high material density and limitation, and achieve the effects of low density, low cost and convenient preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a method for preparing a phenolic resin airgel with a nanofiber network structure, comprising the following steps:

[0050] S1. Dispersing one-dimensional nanomaterials, surfactants, catalysts, phenolic compounds and aldehyde compounds in a solvent to form a sol;

[0051] The one-dimensional nanomaterial is selected from tellurium nanowires, cellulose nanofibers, carbon nanotubes, silver nanowires, calcium silicate nanowires, vanadium oxide nanowires, aluminum oxide nanowires, protein nanofibers and chitin nanofibers at least one of;

[0052] S2, heating the sol to obtain a phenolic resin hydrogel;

[0053] S3, performing supercritical drying on the phenolic resin hydrogel to obtain a phenolic resin airgel having a nanofiber network structure.

[0054]The phenolic resin airgel material prepared by the invention has excellent mechanical properties and low density. Moreover, the preparation method provided by the invention has a simple and contro...

Embodiment 1

[0078] The present embodiment phenolic resin nanofiber airgel and carbon nanofiber airgel are carried out as follows:

[0079] a. Disperse 0.922 g of sodium tellurite (Mayer Reagent) and 10 g of polyvinylpyrrolidone (Sinopharm Chemical Reagent Co., Ltd.) in 330 mL of deionized water, and stir for 1 hour. Then add 33.5mL of ammonia water and 16.5mL of hydrazine hydrate in sequence, stir evenly, put it into a 500mL polytetrafluoroethylene-lined hydrothermal reaction kettle, place it in an oven at 180°C, and conduct a hydrothermal reaction for 3 hours to obtain a tellurium nanowire dispersion.

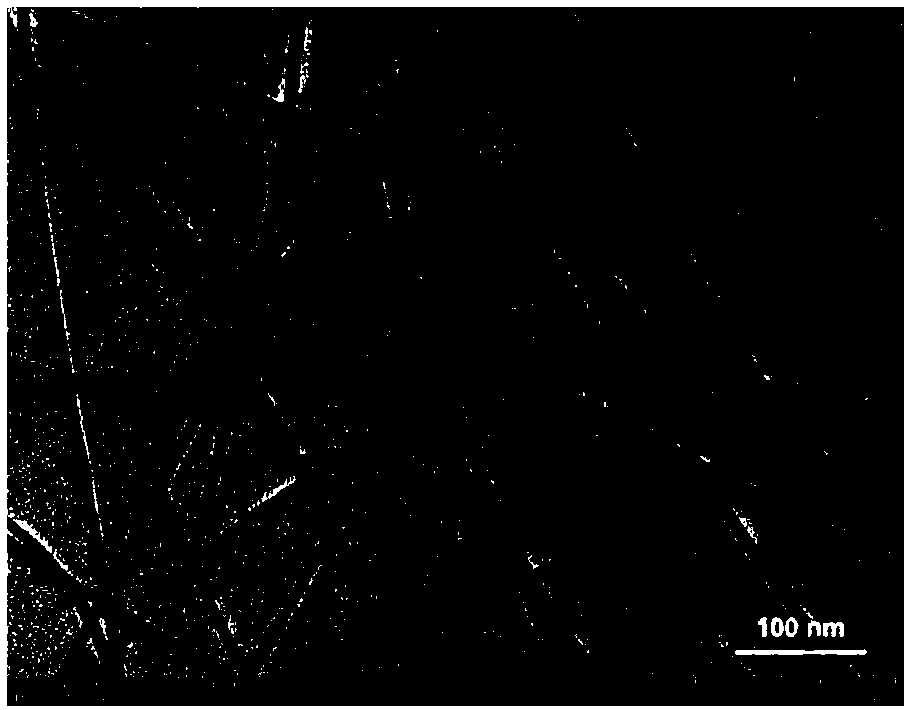

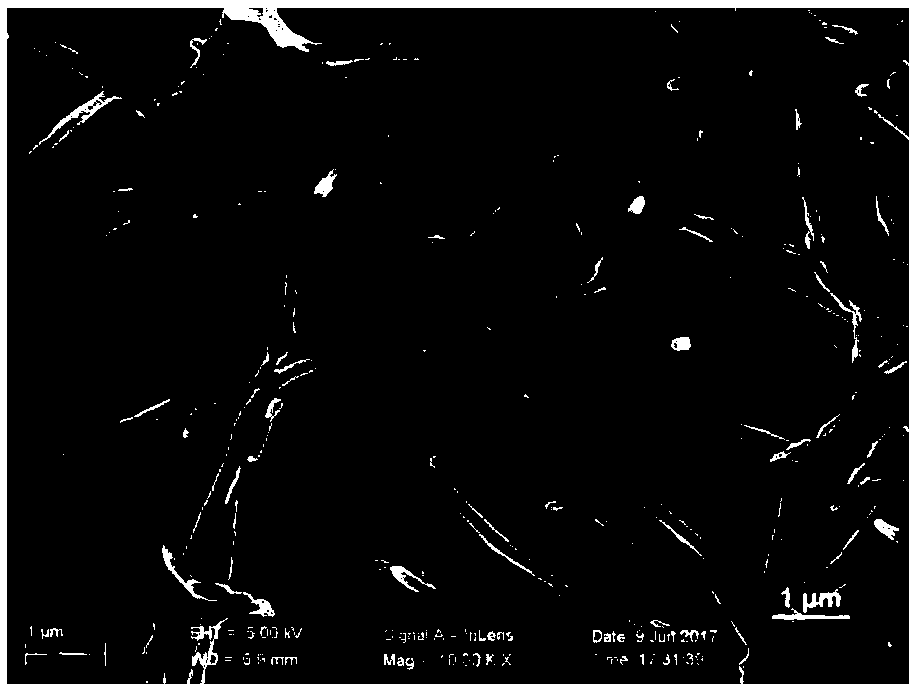

[0080] The transmission electron microscope pictures of the obtained tellurium nanowires are as follows: figure 1 Shown; its diameter is 6 ~ 8nm, the length is hundreds of nanometers to tens of microns.

[0081]b. Take 10 mL of the tellurium nanowire dispersion into a centrifuge tube, add acetone to settle, separate the precipitate, add 10 mL of ethylene glycol, shake vigorously to dispe...

Embodiment 2~3

[0087] The phenolic resin nanofiber airgel material was prepared according to the method of Example 1, the only difference being that the amount of tellurium nanowire dispersion liquid added was different, which were 20mL and 30mL in turn. All the rest are the same, including the amount of resin, catalyst, solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com