A lithium-aluminum-silicon glass-ceramic/silicon carbide/carbon fiber ternary composite wave-absorbing material and its preparation method

A technology of glass-ceramic and wave-absorbing material, applied in the field of wave-absorbing material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A preparation method of a lithium-aluminum-silicon glass-ceramic / silicon carbide / carbon fiber ternary composite absorbing material, comprising the following preparation steps:

[0028] Step 1. Add polyvinyl alcohol particles to deionized water, heat to 95°C, and stir to obtain a 3wt% polyvinyl alcohol aqueous solution by mass fraction; prepare a 0.005mol / L solution of FeNi50 alloy powder as a catalyst and acetylene black powder adding together to the polyvinyl alcohol aqueous solution, ultrasonically dispersing and mechanically stirring until uniformly mixed to obtain a mixed solution;

[0029] Step 2, impregnating the carbon fiber non-woven fabric in the mixed solution, drying at 45°C after impregnation, wherein the diameter of the carbon fiber is 7 μm;

[0030] Step 3: Grow silicon carbide nanowires on the surface of carbon fibers by thermal evaporation, spread the arsenic powder on the bottom of the alumina crucible, interlock the crucibles of the same ...

Embodiment 2

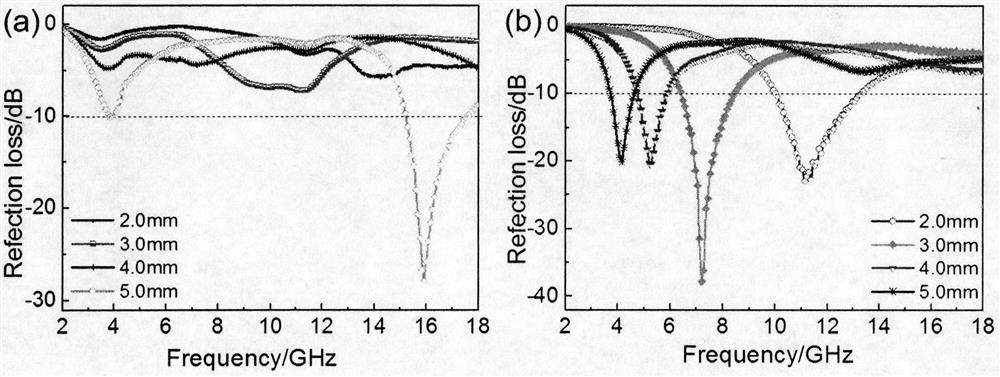

[0034] Example 2: Lithium-aluminum-silicon glass-ceramics / silicon carbide / carbon fiber ternary composite absorbing material prepared by the method of Example 1, including carbon fiber non-woven fabrics with no silicon carbide nanowires grown on the surface, and silicon carbide nanowires grown on the surface Carbon fiber non-woven fabrics and lithium aluminum silicon glass-ceramics, carbon fiber non-woven fabrics with silicon carbide nanowires grown on the surface covered by lithium aluminum silicon glass-ceramics, and carbon fiber non-woven fabrics without silicon carbide nanowires grown on the surface The diameter of silicon carbide nanowires is 30nm by stacking each other; through subsequent mechanical processing, lithium-aluminum-silicon glass-ceramics / silicon carbide / carbon fiber ternary composite absorbing materials with different thicknesses can be obtained.

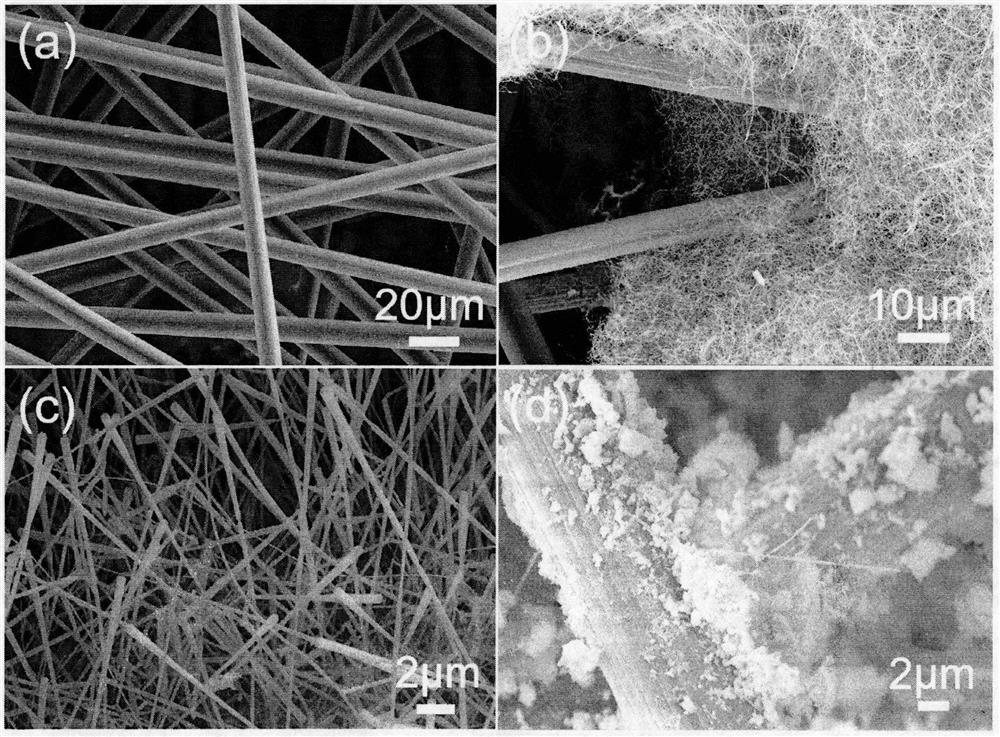

[0035] figure 1 (b) and 1(c) are scanning electron micrographs of the intermediate product silicon carbide / carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com