Tissue engineering tracheal patch culture method and culture system

A technology of tissue engineering and culture method, applied in the field of biomedicine, can solve problems such as granulation tissue hyperplasia, tissue structure differences, inability to exert tracheal physiological and immune functions, etc., and achieve the effect of improving living conditions and restoring physiological functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] According to the location, diameter, and thickness of the damaged trachea suggested by the patient's CT image and tracheal endoscopy, a tracheal patch of appropriate shape and size is designed. Using 3D printing technology, according to the designed size, a culture system for tissue engineered tracheal patches of appropriate size is printed out. This system has the following characteristics:

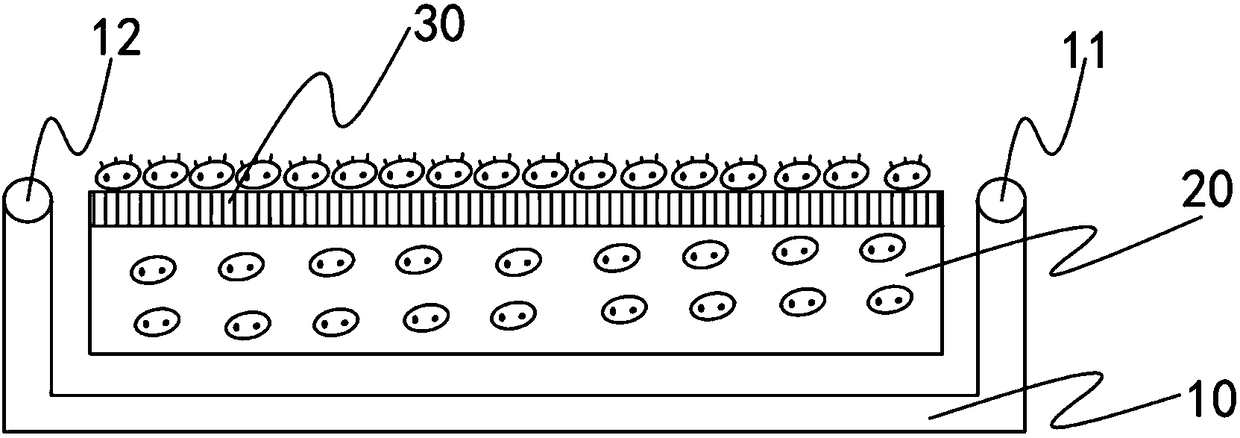

[0040] Such as figure 1 As shown, the system consists of a three-layer structure consisting of a bottom hard material layer 10 of a cell culture dish-like hard material, a middle cell layer 20 of a chondrocyte hydrogel, and a top membrane layer 30 of an epithelial cell membrane.

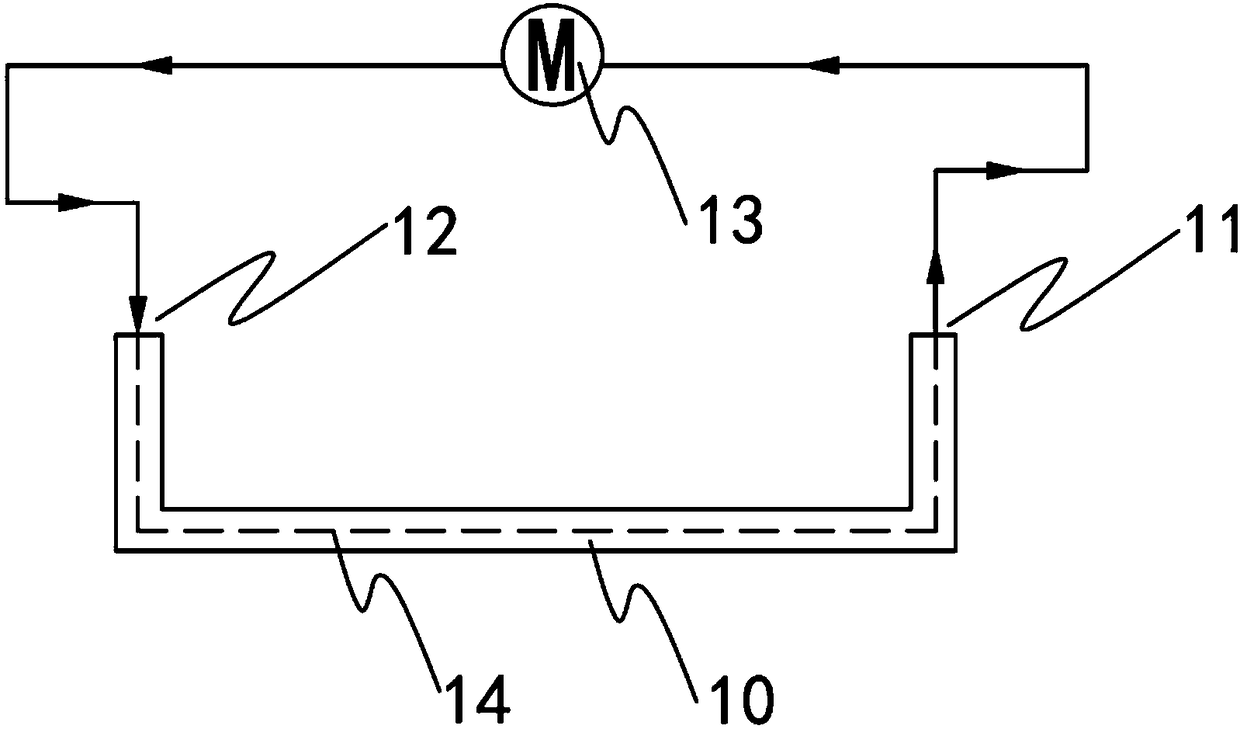

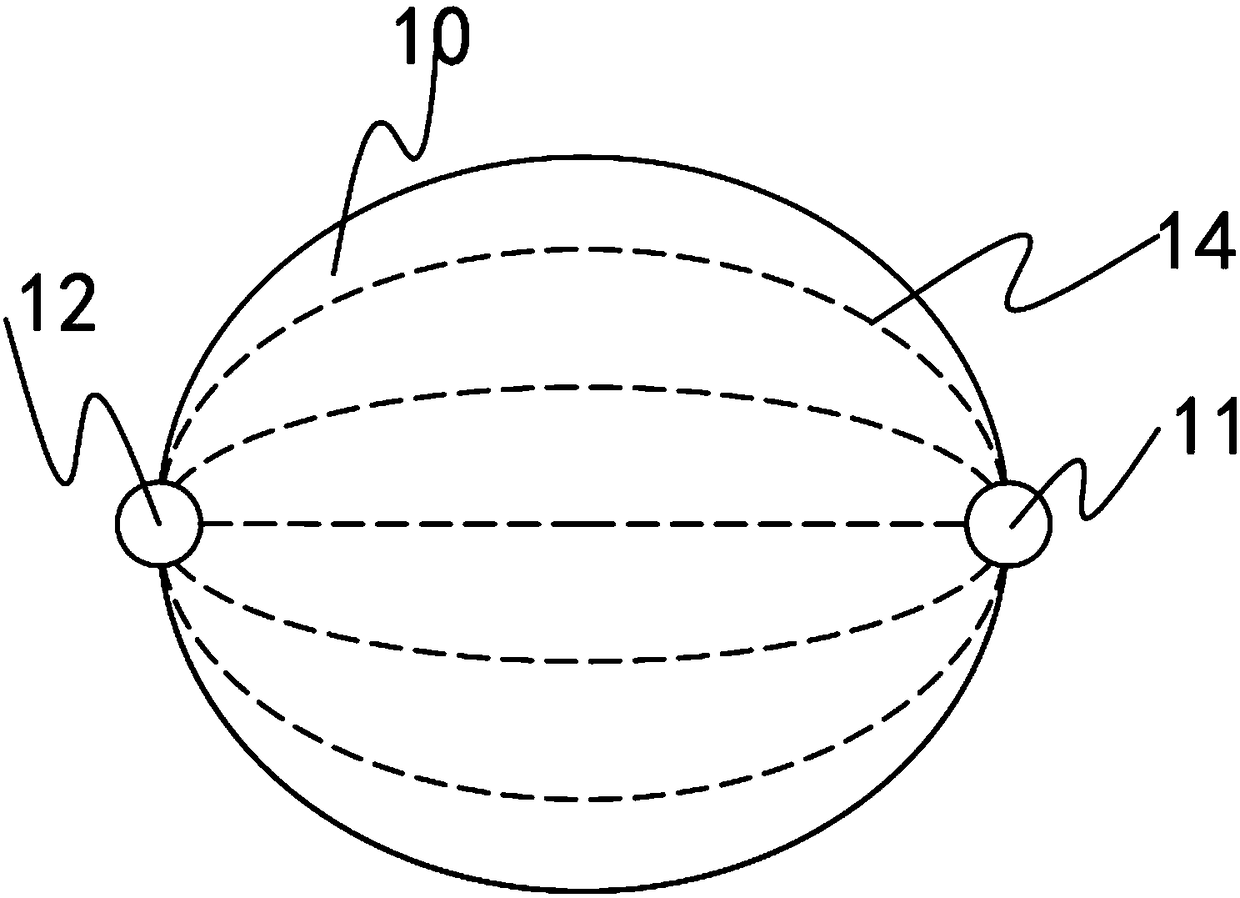

[0041] Such as Figure 2-3 As shown, the bottom hard material layer 10 is made by 3D printing, and the hard material of polylactic acid-caprolactone copolymer material (PLLACL) is used to print into the shape of a petri dish, and the bottom is made by 3D printing. The inlet 12 and the outlet 11 of the ...

Embodiment 2

[0046] Patient XX underwent tracheal side wall resection due to airway lesions, and needed to transplant tracheal substitutes for airway reconstruction. The tissue-engineered tracheal patch culture method constructed by the 3D printing composite tissue cell layered culture system was used to obtain tissue-engineered tracheal substitutes. Specifically include:

[0047] (1) Obtain the patient's autologous cartilage and epithelial cells through bronchoscope biopsy before operation, and culture them in vitro;

[0048] (2) if figure 1 As shown, the dish-shaped bottom hard material layer 10 with a flow channel system is 3D printed using PLLACL material;

[0049](3) suspending the cultured and proliferated chondrocytes with the hydrogel, and then printing the hydrogel chondrocytes above the dish-shaped bottom hard material layer 10 to form the middle cell layer 20;

[0050] (4) Using the epithelial cells obtained in the above step (1), use the cell sheet technology (cellsheet) to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com