Preparation method and application of metal micro-nano material transparent conductive film patterning

A transparent conductive film, micro-nano technology, applied in the direction of equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve problems such as complex processes, high requirements, and high costs. Achieve the effect of improving contact characteristics, reducing resistance value, and reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

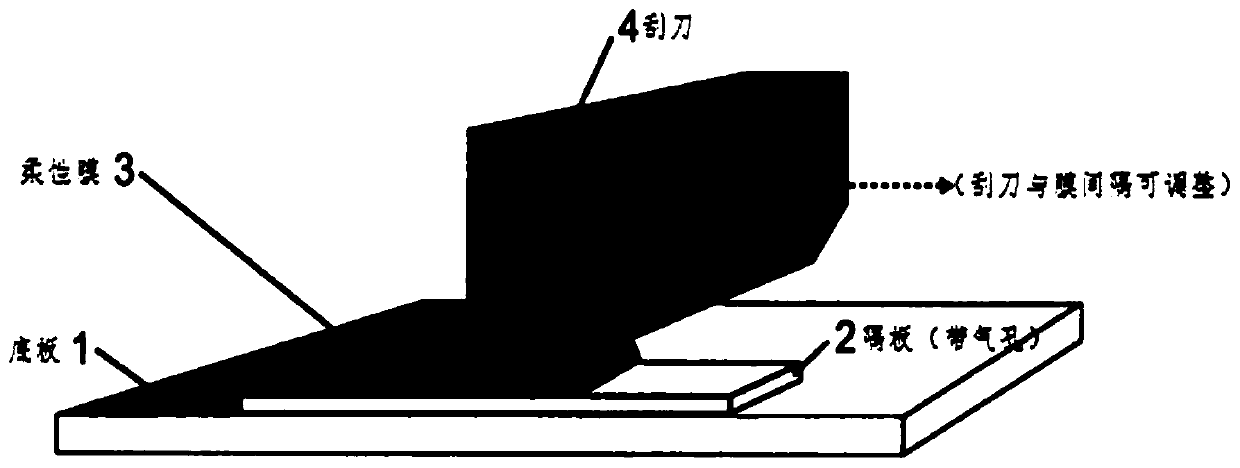

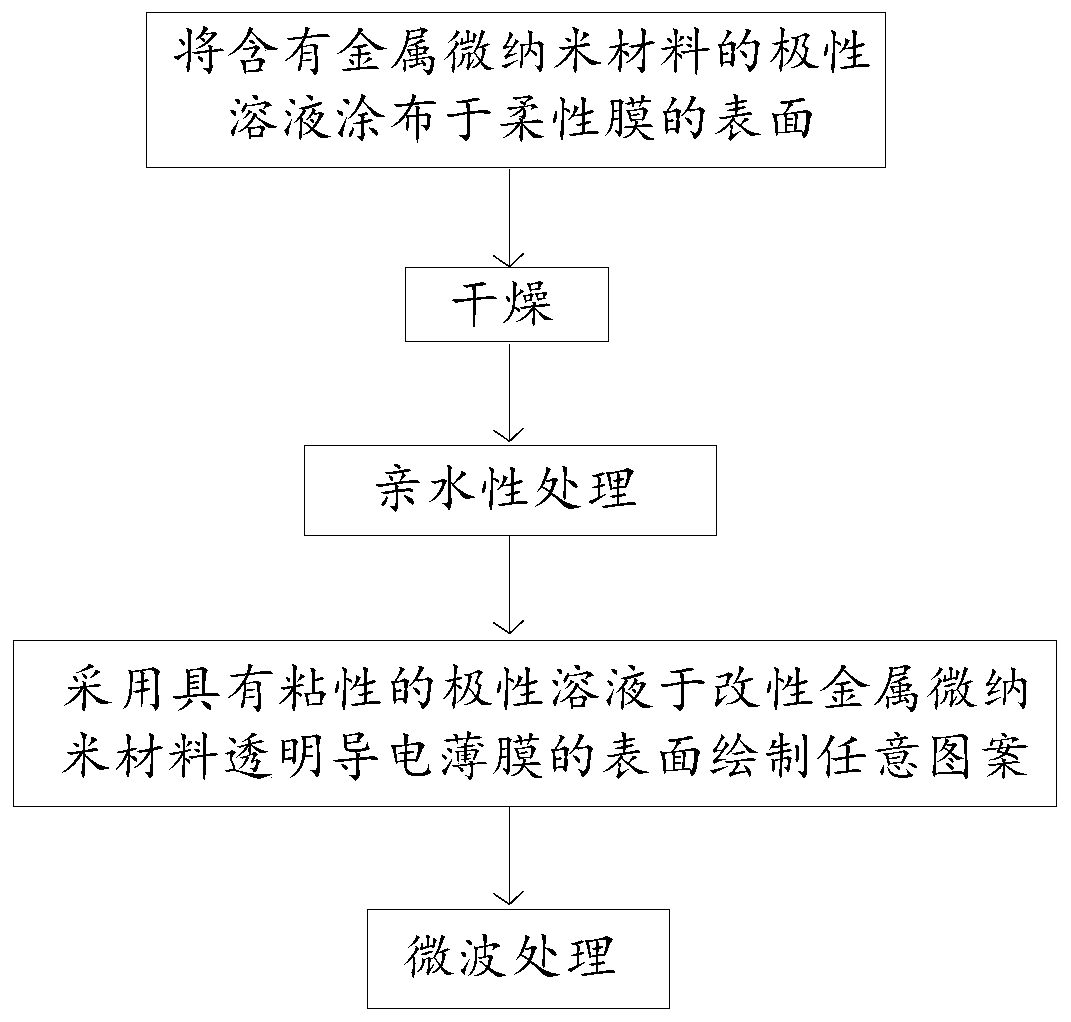

[0038] Specifically, the present invention also provides a preparation method for patterning transparent conductive thin films of metal micro-nano materials, please refer to figure 2 , which includes:

[0039] S1. Coating a polar solution containing metal micro-nano materials on the surface of a flexible film, drying and hydrophilic treatment, to obtain a modified silver nanowire transparent conductive film.

[0040] Wherein, optionally, the metal micro-nano material is Ag, Au, Cu, Pt, Fe, Co, Ni, W, Al, Ti, Sb, Pb, Sn, Zn, In, Ga or alloys thereof or metal oxides thereof At least one of nanowires, microwires, nanotubes and microtubes, preferably, the metal micro-nano material is Ag, Au, Cu, Pt, Fe, Co, Ni, W, Al, Ti, Sb, Pb , Sn, Zn, In, Ga or their alloys or their metal oxide nanowires, microwires, nanotubes or microtubes. Since silver has excellent electrical conductivity, preferably, in a preferred embodiment of the present invention, the metal micro-nano material is si...

Embodiment 1

[0062] Metal micro-nano material-silver nanowire transparent conductive film matrix, which is prepared by the following method:

[0063] (1) First configure a polyol solution of PVP with a certain molecular weight, heat it in a water bath and stir it magnetically to dissolve it completely, and cool it to room temperature. Configure AgNO 3 The polyol solution was placed on a magnetic stirrer to dissolve it completely. At the same time, configure a certain concentration of NaCl solution to completely dissolve it. When mixing the solution, pay attention to the order of addition: first mix the polyol solution of a certain molecular weight PVP and AgNO 3 Mix the polyol solution with a glass rod at room temperature, then add a certain amount of NaCl solution, and stir evenly.

[0064] Transfer the uniformly mixed solution to the reactor, and use the alcohol thermal method to prepare silver nanowires. The first choice is a closed system, which can block the oxygen in the air. Air...

Embodiment 2

[0068] A patterned metal micro-nano material-silver nanowire transparent conductive film, which is prepared by the following method:

[0069]The surface of the silver nanowire transparent conductive film substrate prepared in Example 1 is subjected to hydrophilic treatment, and after the treatment, the mixed polar solution with a certain viscosity configured by PVP and water is used to quickly draw the target pattern for the "ink", and then the It is placed flat in a microwave device to heat the film with microwaves, and the silver wire at the corresponding position is fused through the interaction between the microwave and the polar solution, and the corresponding pattern can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com