Transdermal patch containing rotigotine, and preparation method thereof

The technology of a transdermal patch and a softener is applied to the transdermal patch containing rotigotine and the field of preparation thereof, and can solve the problem of low skin penetration rate, low penetration rate, inability to achieve therapeutic effect and stability and other problems, to achieve the effects of easy availability of materials, improved initial viscosity, and improved transdermal release performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

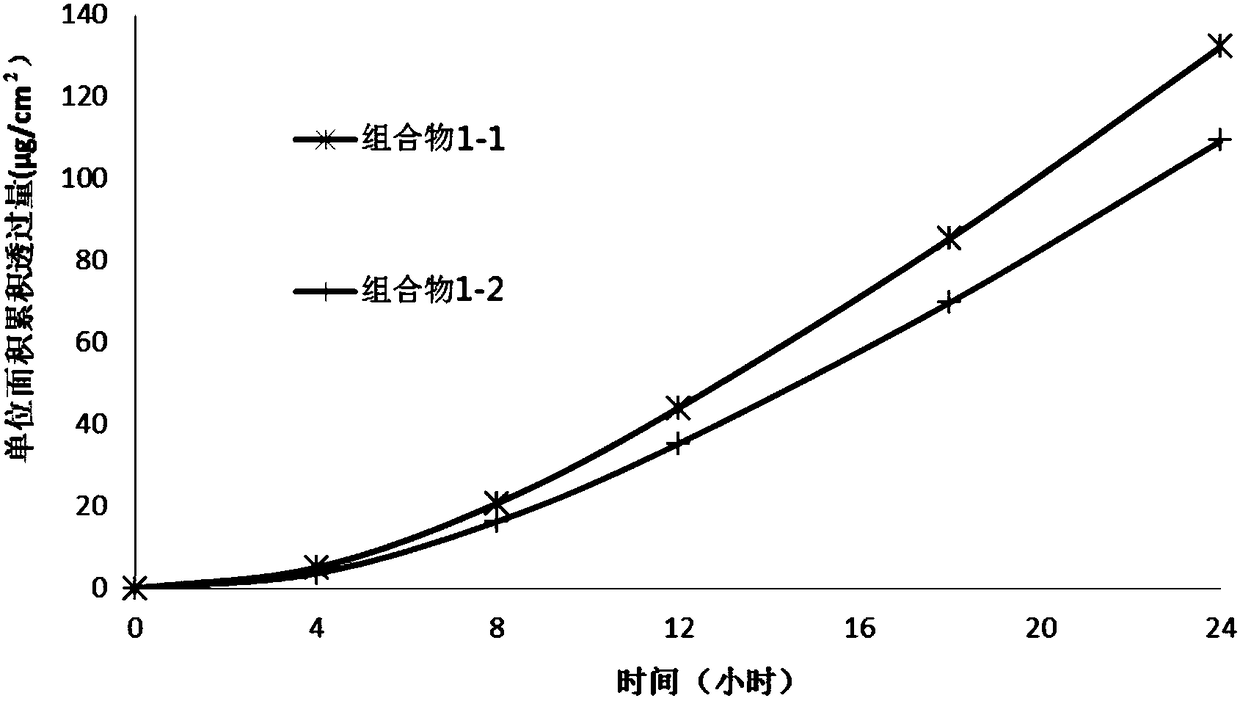

[0042] Example 1 is used to prepare the preparation of the transdermal patch composition containing rotigotine

[0043] Take a suitable glass container, add the prescribed amount of rotigotine and DL-α-tocopherol in Table 1 to an appropriate amount of absolute ethanol solution, and stir until the mixture is completely dissolved. Take the polyisobutylene B100, B10, and low-molecular-weight polybutene in the prescription amount in Table 1 and stir and mix evenly to form a polyisobutylene pressure-sensitive adhesive. Add colloidal silicon dioxide and light liquid paraffin to the above-mentioned pressure-sensitive adhesive, and stir and mix until uniform ; Then add the drug solution, stir while adding, until a uniform dispersion system is obtained, and prepare by vacuum degassing to obtain compositions 1-1 and 1-2.

[0044] Using a laboratory small-scale coating machine (England, Elcometer), the obtained compositions 1-1 and 1-2 are coated on the release film, and the specific coa...

Embodiment 2

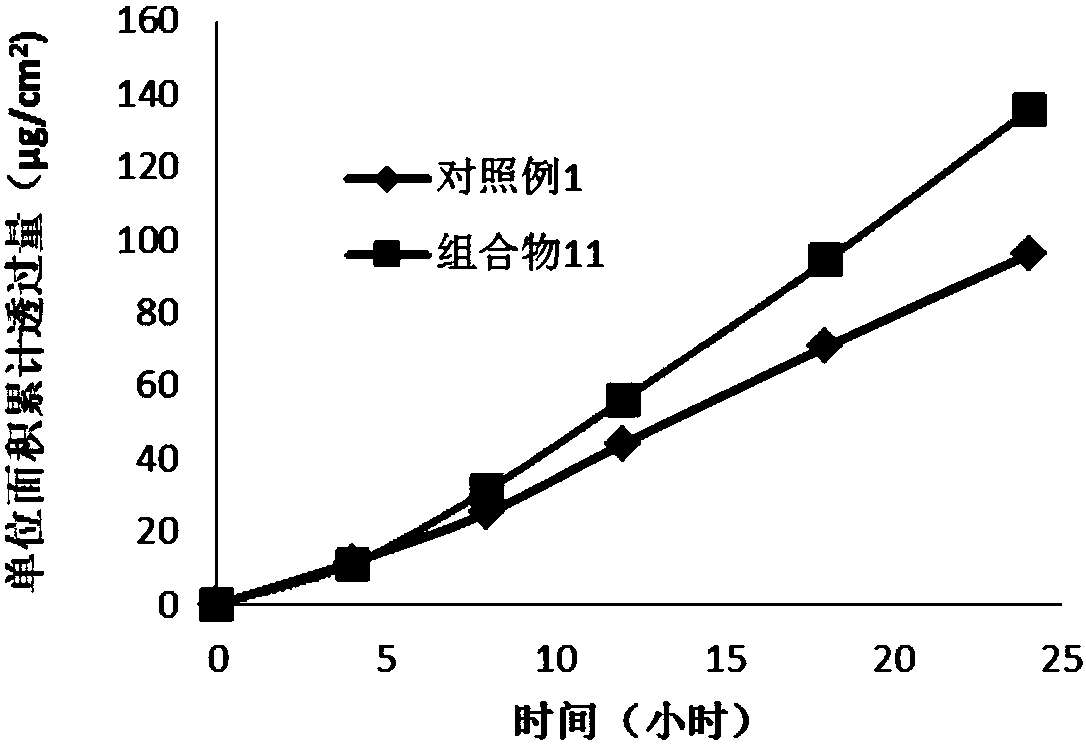

[0053] The comparative test of embodiment 2 different softening agents

[0054] Screen the types of softeners in order to improve their permeability behavior by changing the softeners, and investigate three different softeners: light liquid paraffin, liquid paraffin, and glycerin. The components and amounts used are shown in Table 3. Preparation method The method described in Example 1 was used.

[0055] Table 3. Components and dosages used

[0056]

[0057]

[0058] Wherein, the above-mentioned polyisobutylene pressure-sensitive adhesive adopts polyisobutylene (Polyisobutylene (oppanol B100, viscosity average molecular weight 1,000,000)) that is 30.7 parts by weight, polyisobutylene (Polyisobutylene (oppanol B10, viscosity average molecular weight 30,000)) that is 30.7 parts by weight, Mix evenly with low molecular weight polybutene (HV-300, viscosity average molecular weight 1,260) of 5 parts by weight to form a polyisobutylene pressure-sensitive adhesive. The polyiso...

Embodiment 3

[0072] Example 3 is used to prepare the preparation of the transdermal patch composition containing rotigotine

[0073] Composition 1:

[0074] Take a suitable glass container, add the prescribed amount of rotigotine, ascorbyl palmitate and all-racem-a-tocopherol in Table 7 to an appropriate amount of absolute ethanol solution, and stir until the mixture is completely dissolved.

[0075] Take the polyisobutylene pressure-sensitive adhesive of the prescription amount in Table 1, add liquid paraffin, stir and mix until uniform; then add the drug solution into it, stir while adding, until a uniform dispersion system is obtained, and vacuum degassing. Use laboratory small-scale coating machine (England, Elcometer) to coat the colloid system obtained on the release film. The specific coating thickness should ensure that the drug content per unit area in the patch after drying is constant, that is, every 10cm 2 The patch contains rotigotine 4.5mg. Form a uniform thin layer, dry a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com