a mos 2 /srfe 12 o 19 Preparation method of composite magnetic photocatalyst

A srfe12o19, photocatalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as difficult recycling, secondary pollution, etc., and achieve easy operation, high production efficiency, and high photocatalysis active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

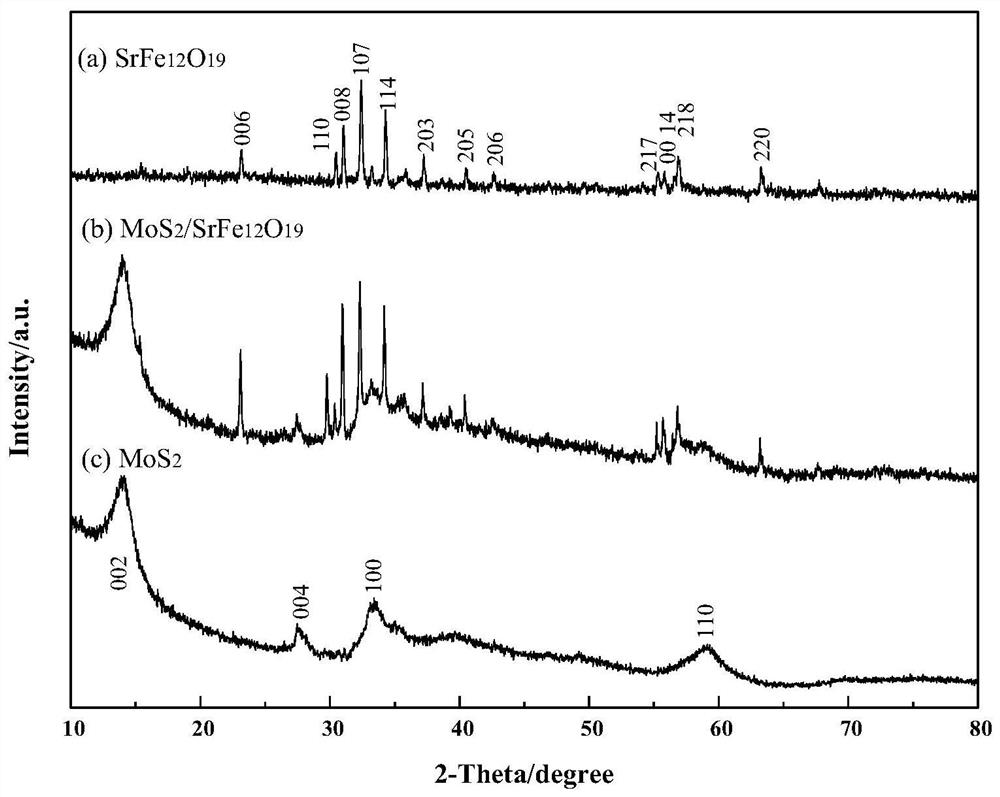

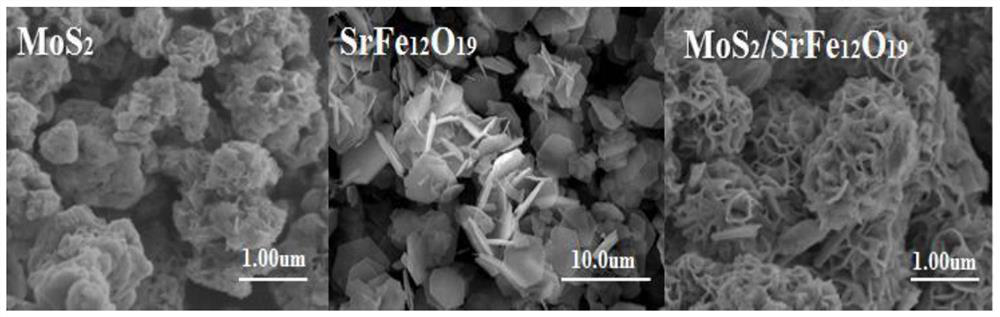

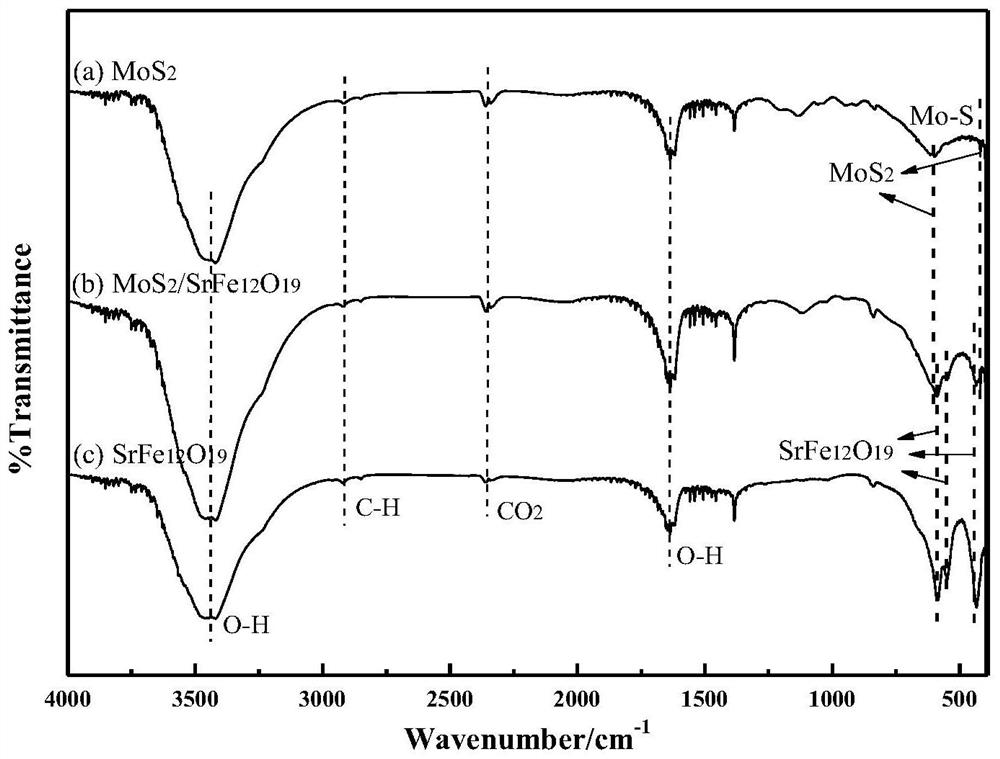

[0021] A kind of MoS 2 / SrFe 12 o 19 The preparation method of composite magnetic photocatalyst, concrete steps are as follows:

[0022] (1) SrFe 12 o19 preparation of

[0023] Weigh 0.7465g SrCl respectively 2 ·6H 2 O and 6.0545g FeCl 3 ·6H 2 O reagent was ultrasonically dissolved with 38mL deionized water to obtain mixed solution A; 8.736g NaOH reagent was weighed and dissolved ultrasonically with 20mL deionized water to obtain solution B; Add it dropwise to the mixed solution A, and keep stirring for 15 minutes until the solution is fully mixed to obtain SrFe 12 o 19 Precursor C: Pour precursor C into a 100mL hydrothermal kettle, react at 200°C for 24 hours, take it out, naturally cool to room temperature, filter with suction, and wash with deionized water until the filtrate is neutral, then place the filter cake at 80°C Dry in oven for 12h, take out and grind to get SrFe 12 o 19 .

[0024] (2)MoS 2 / SrFe 12 o 19 preparation of

[0025] Weigh 0.4319g MoO re...

Embodiment 2

[0027] A kind of MoS 2 / SrFe 12 o 19 The preparation method of composite magnetic photocatalyst, concrete steps are as follows:

[0028] (1) With the step (1) of embodiment 1.

[0029] (2)MoS 2 / SrFe 12 o 19 preparation of

[0030] Weigh 0.4319g MoO respectively 3 and 0.8746g KSCN reagent, added to 60mL deionized water, ultrasonic for 15min and mechanically stirred for 30min to make it fully mixed to obtain solution A; according to the theory, SrFe 12 o 19 The mass percentage in the composite is 10wt%, and the prepared SrFe 12 o 19 Add the powder into solution A, and continue to stir mechanically for 1 hour to obtain suspension B. Put the suspension B into a 100mL hydrothermal kettle, react at 200°C for 24 hours, take it out, cool to room temperature, filter with suction, and use Alternately washed several times with ionic water and absolute ethanol, dried the filter cake in an oven at 80°C for 12 hours, and obtained MoS after grinding 2 / SrFe 12 o 19 .

Embodiment 3

[0032] A kind of MoS 2 / SrFe 12 o 19 The preparation method of composite magnetic photocatalyst, concrete steps are as follows:

[0033] (1) With the step (1) of embodiment 1.

[0034] (2)MoS 2 / SrFe 12 o 19 preparation of

[0035] Weigh 0.4319g MoO respectively 3 and 0.8746g KSCN reagent, added to 60mL deionized water, ultrasonic for 15min and mechanically stirred for 30min to make it fully mixed to obtain solution A; according to the theory, SrFe 12 o 19 The mass percentage in the composite is 15wt%, and the prepared SrFe 12 o 19 Add the powder into solution A, and continue to stir mechanically for 1 hour to obtain suspension B. Put the suspension B into a 100mL hydrothermal kettle, react at 200°C for 24 hours, take it out, cool to room temperature, filter with suction, and use Alternately washed several times with ionic water and absolute ethanol, dried the filter cake in an oven at 80°C for 12 hours, and obtained MoS after grinding 2 / SrFe 12 o 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com