A kind of purification method of high carbon graphite

A purification method, graphite technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of unstable graphite purity, cumbersome operation steps, and long time, and achieve low cost, simple operation steps, and time-saving short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The purification of embodiment 1 high carbon graphite

[0036]1. Graphite composition to be purified:

[0037] Table 1

[0038] project Purity (C%) Fe(μg / g) Si (μg / g) Al (μg / g) Ni (μg / g) Cu(μg / g) parameter 94 2187.01 566.07 225.46 71.00 22.11

[0039] 2. Method

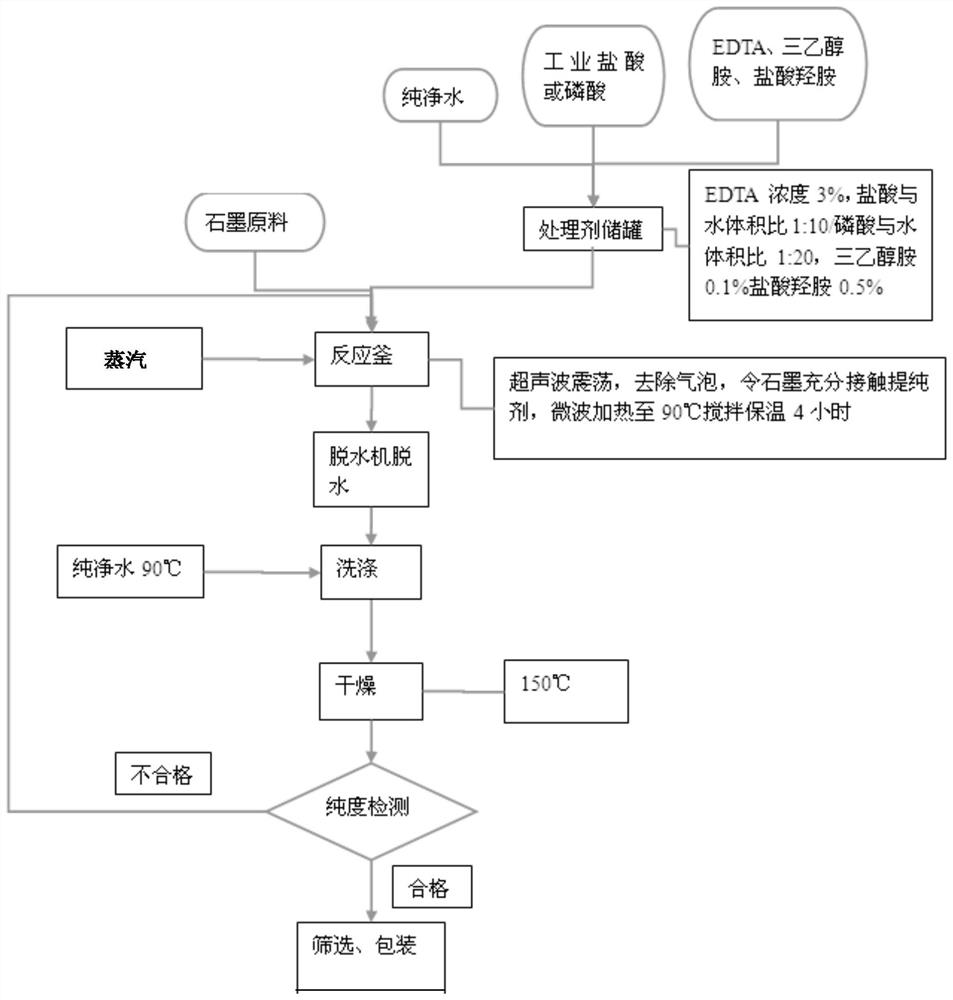

[0040] Flowchart such as figure 2 shown.

[0041] (1) placing the high-carbon graphite with a carbon content of 94% in the reactor;

[0042] (2) Preparation of purification agent: put purified water, industrial hydrochloric acid, EDTA, triethanolamine, and hydroxylamine hydrochloride in the treatment agent storage tank for mixing, wherein the volume ratio of industrial hydrochloric acid to purified water is 1:10, and the final concentration of EDTA is 3w / w%, the final concentration of triethanolamine is 0.1w / w%, and the final concentration of hydroxylamine hydrochloride is 0.5w / w%;

[0043] (3) Purification: add the purifying agent into the reaction kettle so that th...

Embodiment 2

[0050] The purification of embodiment 2 high carbon graphite

[0051] 1. Graphite components to be purified: see Table 1

[0052] 2. Method

[0053] Flowchart such as figure 2 shown.

[0054] (1) placing the high-carbon graphite with a carbon content of 94% in the reactor;

[0055] (2) Preparation of purification agent: put pure water, phosphoric acid, EDTA, triethanolamine, and hydroxylamine hydrochloride in the treatment agent storage tank for mixing, wherein the volume ratio of phosphoric acid to pure water is 1:20, and the final concentration of EDTA is 3w / w %, the final concentration of triethanolamine is 0.1w / w%, and the final concentration of hydroxylamine hydrochloride is 0.5w / w%;

[0056] (3) Purification: add the purifying agent into the reaction kettle so that the mass ratio of EDTA to graphite is 1:5, introduce steam at 230°C, ultrasonically oscillate to remove bubbles, make the graphite fully contact with the purifying agent, heat to 90°C with microwave and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com