Method for preparing silver-loaded hydrogen sulfide poisoning-resistant 4A molecular sieve from attapulgite serving as raw material

A technology resistant to hydrogen sulfide and attapulgite, applied in separation methods, chemical instruments and methods, molecular sieves and alkali exchange compounds, etc., can solve the problems of reduced catalytic activity, easy poisoning and deactivation, and adsorbent poisoning, and achieves no secondary Secondary pollution, low equipment requirements, strong dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

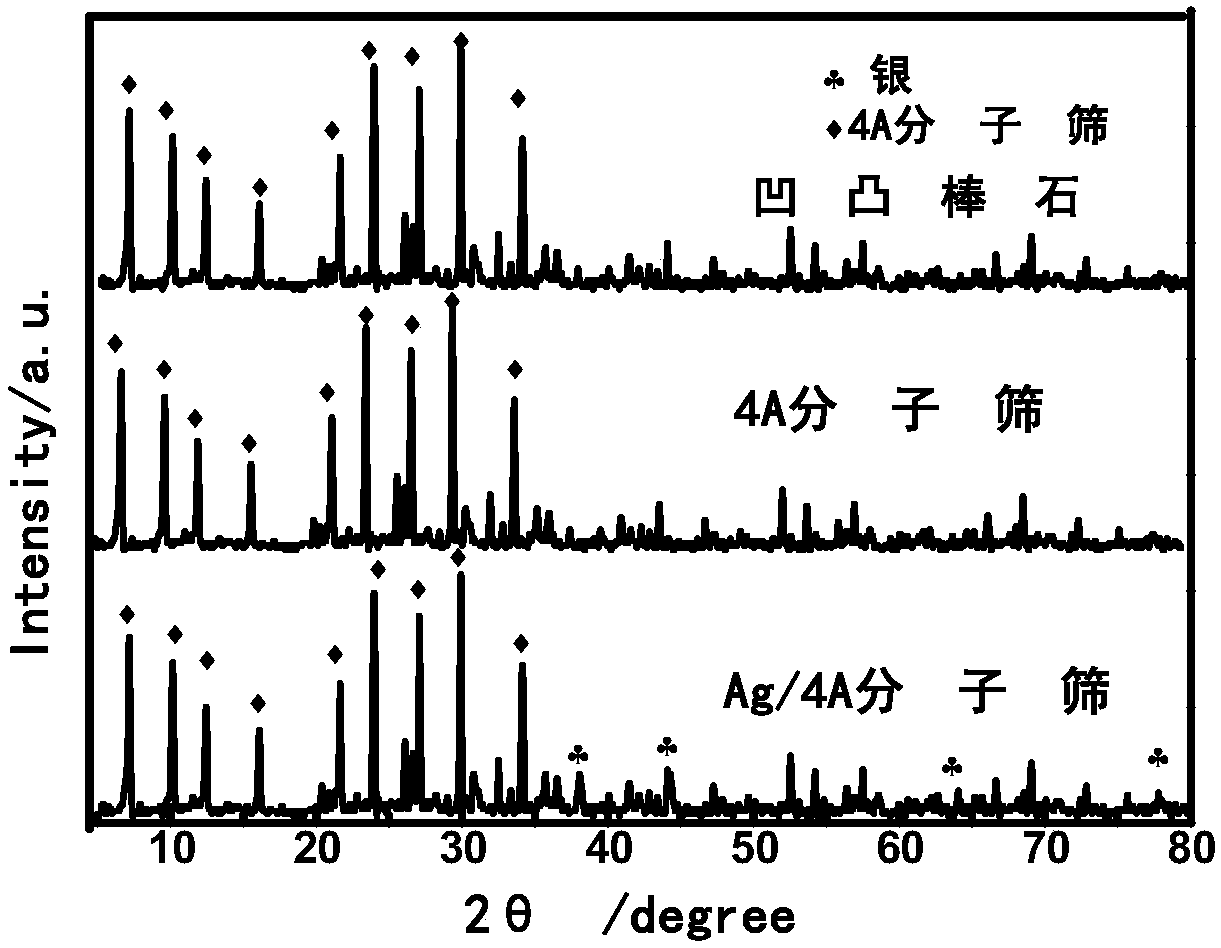

Embodiment 1

[0051] The first step is to grind the attapulgite, wash it with distilled water, filter it, put it into a muffle furnace for calcination at 300°C for 3 hours, then carry out acidification treatment, add 8% sulfuric acid and heat it to boiling for 1 hour, wash it with distilled water until it is neutral, and dry it Finally, grind through a 100-mesh sieve. Attapulgite SiO 2 The content is 57.2%, and the total content of Mg, Al, Fe is 24.1%.

[0052] Step 2: Mix the sieved attapulgite with 30% sodium hydroxide solution, put it into a round-bottomed flask, place it in a microwave oven with a reflux device, and heat it to 80°C for reflux for 4 hours;

[0053] The third step, preparation of sodium aluminate solution: put a certain amount of sodium aluminate in a beaker, add a small amount of water, and stir at 40°C for 2 hours to obtain a certain concentration of sodium aluminate solution;

[0054] The fourth step, crystallization, sodium aluminate solution is added to the attapul...

Embodiment 2

[0058] The difference from Example 1 is that

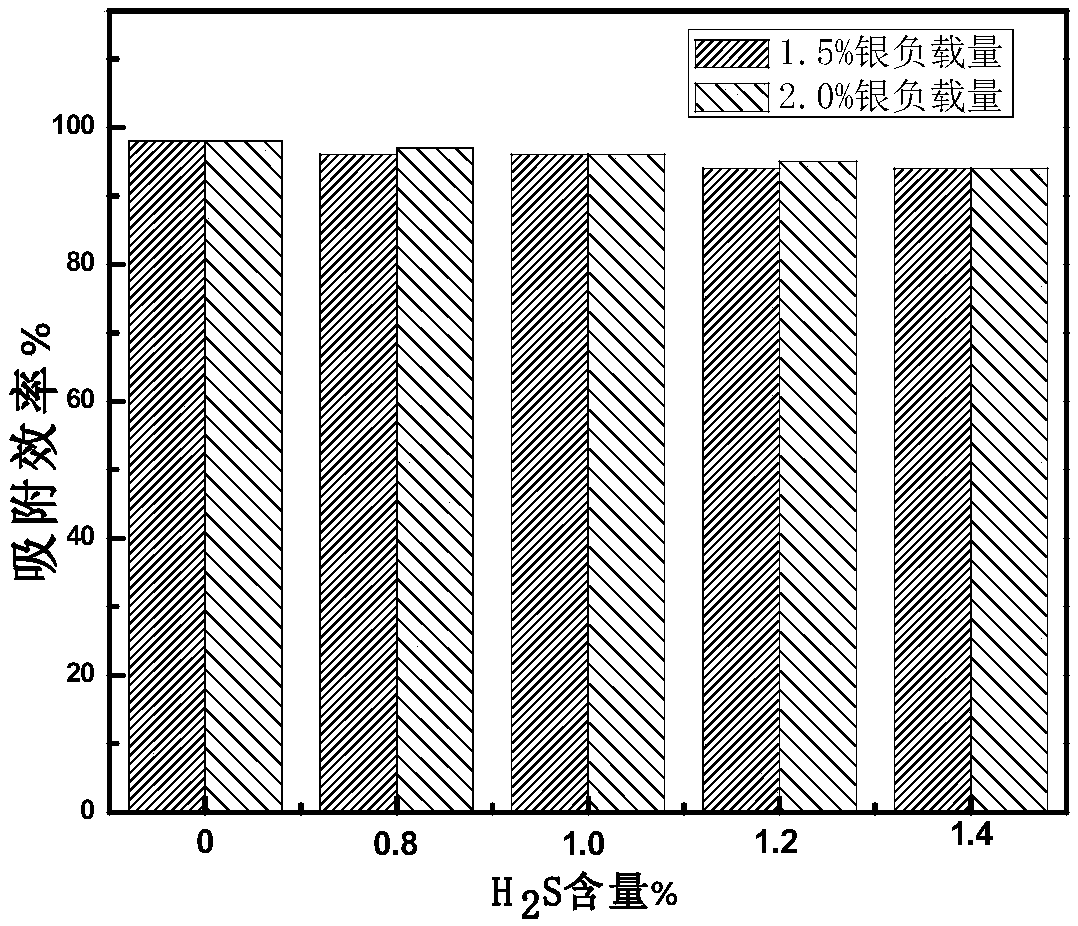

[0059] In the fifth step, the 4A molecular sieve with a silver loading of 1.5% is controlled.

[0060] Choose simulated natural gas H 2 The S content is 1.2%, and the methane content is 85%. The rest is N 2 Conduct mercury removal experiments. During the experiment CH 4 The flow rate is 600ml / min, and H 2 S control content is about 1.2%, carrier gas N 2 The flow rate was 100ml / min for the mercury removal experiment. The experimental results show that the mercury removal efficiency is 96%.

Embodiment 3

[0062] The difference from Example 1 is:

[0063] In the fifth step, the 4A molecular sieve with a silver load of 2% is controlled.

[0064] Choose simulated natural gas H 2 The S content is 1.2%, and the methane content is 85%. The rest is N 2 Carry out the mercury removal experiment, CH 4 The flow rate is 600ml / min, and H 2 S control content is about 1.2%, carrier gas N 2 The flow rate was 100ml / min for the mercury removal experiment. The experimental results show that the mercury removal efficiency is 96%.

[0065] It can be seen from the above-mentioned Examples 1-3 that the amount of silver loaded in the present invention should be controlled at 1.0%-2.0%.

[0066] The concentration of hydrogen sulfide also affects the mercury removal efficiency.

[0067] The present invention studies the preparation of silver-loaded 4A molecular sieves in different H 2 The effect of mercury removal performance on the resistance to hydrogen sulfide poisoning under the atmosphere ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com