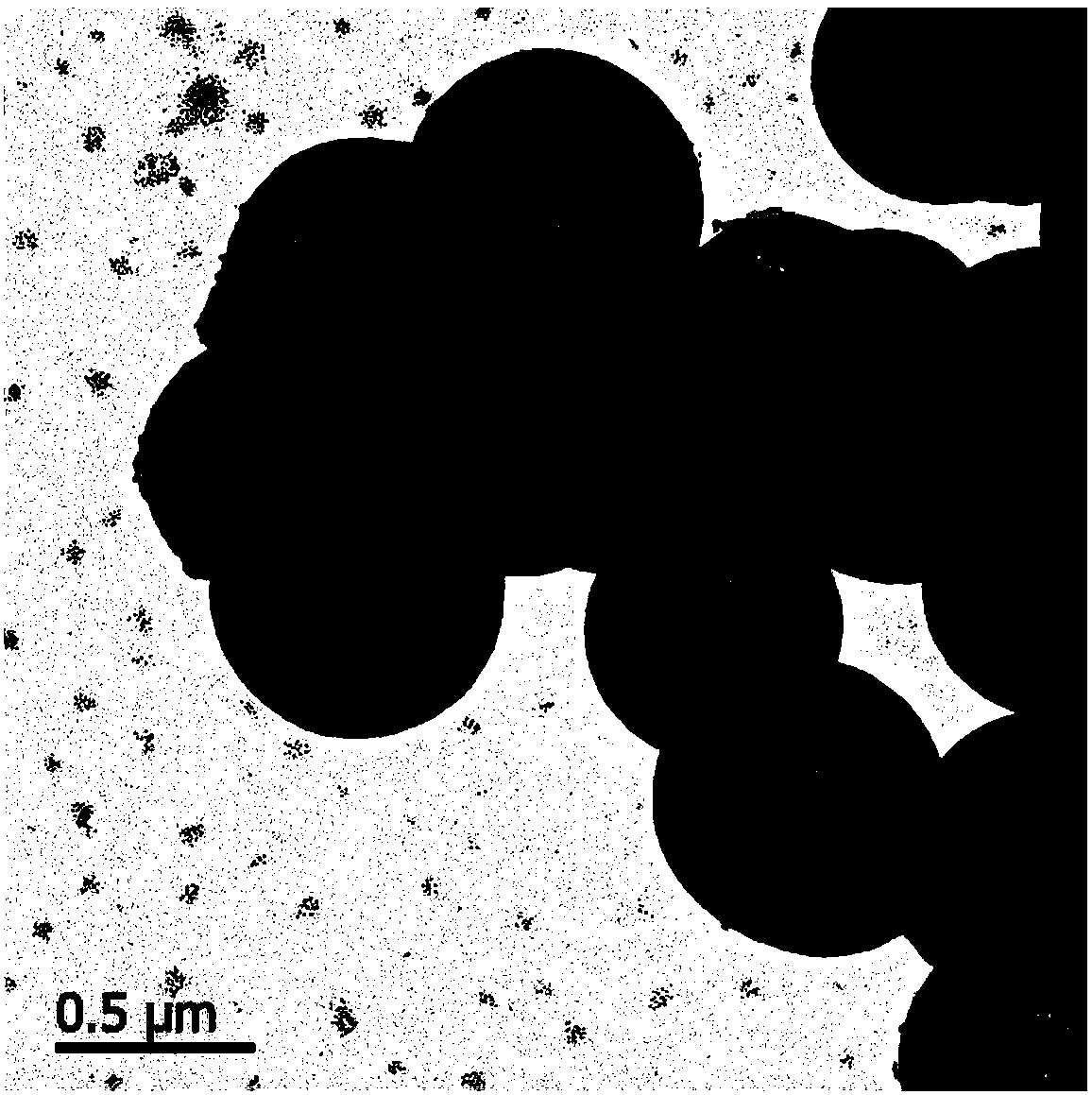

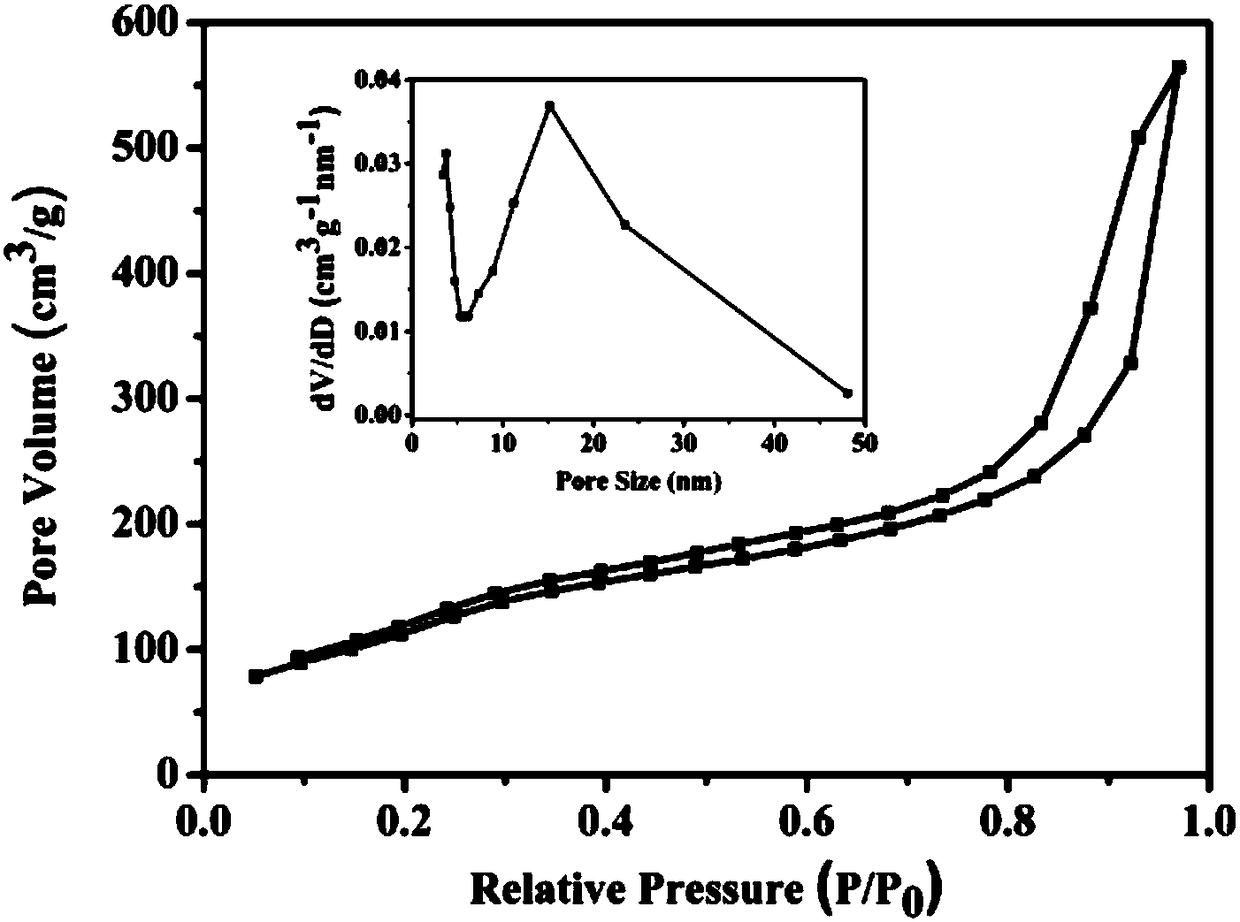

Preparation method and application of hollow mesoporous bioglass microspheres

A technology of bioglass and empty mesopores, applied in the direction of inorganic non-effective ingredients, can solve the problems of affecting bone formation speed, causing inflammatory reactions, small specific surface area, etc., achieving long drug release cycle, high drug loading, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the hollow mesoporous biological glass microspheres provided in this embodiment is as follows:

[0035] (1) Dissolve 0.1g of cetyltrimethylammonium bromide (CTAB) in 75mL of ethanol aqueous solution, wherein the volume ratio of alcohol / water is 0.1, stir for 5min, and the temperature is 20°C;

[0036] (2) Add 1 mL of ammonia water with a mass concentration of 37% into the system of step (1), and stir for 1 min;

[0037] (3) Add 1 mL of tetraethyl orthosilicate (TEOS) into the system of step (2), and stir for 10 min;

[0038] (4) Add 0.45g of calcium nitrate tetrahydrate (CN) into the system of step (3), and stir for 2h;

[0039] (5) Centrifuge the solution obtained in step (4), wash it 3 times with deionized water, then add it to 100mL deionized water, and mix well;

[0040] (6) Place the solution obtained in step (5) in a hydrothermal reaction kettle, and heat it at 50° C. for 24 hours;

[0041] (7) centrifuging the solution in step (6) to ...

Embodiment 2

[0045] The preparation method of the hollow mesoporous biological glass microspheres provided in this embodiment is as follows:

[0046] (1) Dissolve 0.50g of cetyltrimethylammonium bromide (CTAB) in 75mL of ethanol aqueous solution, wherein the volume ratio of alcohol / water is 0.5, stir for 15min, and the temperature is 60°C;

[0047] (2) Add 2 mL of ammonia water with a mass concentration of 37% into the system of step (1), and stir for 5 min;

[0048] (3) Add 2 mL of tetraethyl orthosilicate (TEOS) into the system of step (2), and stir for 30 min;

[0049] (4) Add 0.9g calcium nitrate tetrahydrate (CN) into the system of step (3), and stir for 8h;

[0050] (5) Centrifuge the solution obtained in step (4), wash it 3 times with deionized water, then add it to 200mL deionized water, and mix well;

[0051] (6) Place the solution obtained in step (5) in a hydrothermal reaction kettle, and heat it at 80° C. for 12 hours;

[0052] (7) The white solid obtained by centrifuging th...

Embodiment 3

[0056] The preparation method of the hollow mesoporous biological glass microspheres provided in this embodiment is as follows:

[0057] (1) Dissolve 0.50 g of cetyltrimethylammonium bromide (CTAB) in 150 mL of aqueous ethanol, wherein the alcohol / water volume ratio is 1, and stir for 15 min;

[0058] (2) Add 5 mL of ammonia water with a mass concentration of 37% into the system of step (1), and stir for 5 min;

[0059] (3) Add 12mL tetraethyl orthosilicate (TEOS) into the system of step (2), and stir for 20min;

[0060] (4) Add 4g of calcium nitrate tetrahydrate (CN) into the system of step (3), and stir for 24h;

[0061] (5) Centrifuge the solution obtained in step (4), wash it 3 times with deionized water, then add it to 500mL deionized water, and mix well;

[0062] (6) Place the solution obtained in step (5) in a hydrothermal reaction kettle, and heat it at 120°C for 24 hours;

[0063] (7) centrifuging the solution in step (6) to obtain a white solid, washing with water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com