Comprehensive utilization method for organic resin wastes

A technology of organic resin and waste, applied in the field of harmless disposal and comprehensive utilization of industrial solid waste, can solve the problems of toxic and harmful, secondary pollution of ecological environment and human health, etc. Effects of safe disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

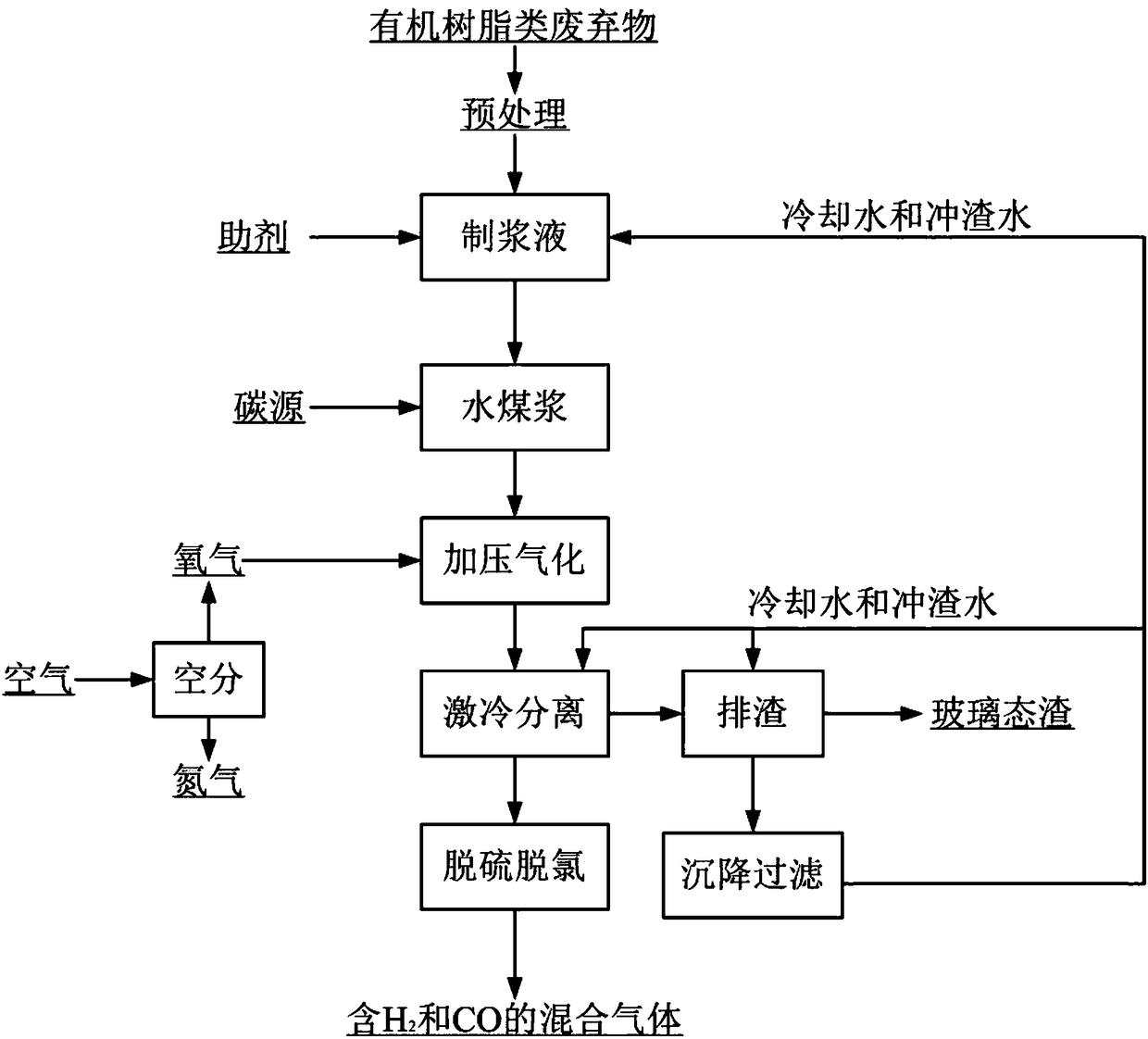

[0062] The present embodiment provides a kind of comprehensive utilization method of organic resin waste, such as figure 1 As shown, the method includes the following steps:

[0063] (1) 3.2t of waste ion exchange resin produced by Hyosung Chemical was crushed, then mixed evenly with 16t of slag washing water and 0.032t of sodium naphthalenesulfonate, with a mass ratio of 100:500:1, to prepare a slurry;

[0064] (2) The slurrying liquid obtained in step (1) is mixed with 27.52t coal evenly, and its mass ratio is 100:143.1, and it is subjected to refining treatment to obtain a solid content of 65.71wt%, and a viscosity of 1523mPa·s coal-water slurry;

[0065] (3) Spray the coal-water slurry obtained in step (2) into the gasification furnace with a special nozzle, and in an atmosphere containing 99.7% (volume content) oxygen, at a temperature of 1300 ° C and a pressure of 2.5 MPa Carry out gasification reaction for 15s to obtain gaseous products and liquid slag;

[0066] (4) C...

Embodiment 2

[0069] The present embodiment provides a kind of comprehensive utilization method of organic resin waste, and described method comprises the following steps:

[0070] (1) Melting the waste resin produced by 2.31t of Yibaoxin, and then mixing it with 6.93t of slag washing water and 0.064t of potassium lignosulfonate in a mass ratio of 100:300:2 to prepare a slurry;

[0071] (2) Mix the pulping solution obtained in step (1) with 13.48t coke powder evenly, the mass ratio of which is 100:144.8, and perform a refining treatment to obtain a coal-water slurry with a solid content of 69.30wt% and a viscosity of 1648mPa·s ;

[0072] (3) Spray the coal-water slurry obtained in step (2) into the gasification furnace with a special nozzle, and in an atmosphere containing 99.5% (volume content) oxygen, at a temperature of 1600 ° C and a pressure of 0.5 MPa Perform gasification reaction for 8s to obtain gaseous products and liquid slag;

[0073] (4) Chill the gaseous product and liquid sl...

Embodiment 3

[0076] The present embodiment provides a kind of comprehensive utilization method of organic resin waste, and described method comprises the following steps:

[0077] (1) Melting 3 tons of waste resin produced by Modern Pharmaceutical Industry, and then mixing it with 3 tons of slag washing water and 0.03 tons of sodium sulfonated humate, the mass ratio of which is 100:300:1, to prepare slurry;

[0078](2) mixing the pulping liquid obtained in step (1) with 6.54t of charcoal evenly, and its mass ratio is 100:105.3, and carrying out refining treatment to obtain a solid content of 75wt%, and a viscosity of 1898mPa·s coal water slurry;

[0079] (3) The coal-water slurry obtained in step (2) is sprayed into the gasification furnace with a special nozzle, and in an atmosphere containing 99.8% (volume content) oxygen, the temperature is 1100 ° C and the pressure is 4 MPa. Gasification reaction for 16s to obtain gaseous products and liquid slag;

[0080] (4) Chill the gaseous produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com