Plasma generation method and device, and semiconductor processing equipment

A plasma and generation method technology, applied in the field of magnetron sputtering, can solve the problems of plasma inability to glow, short loading time, and difficult matching, so as to reduce plasma-induced damage, expand the process window, and improve The effect of the plasma process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

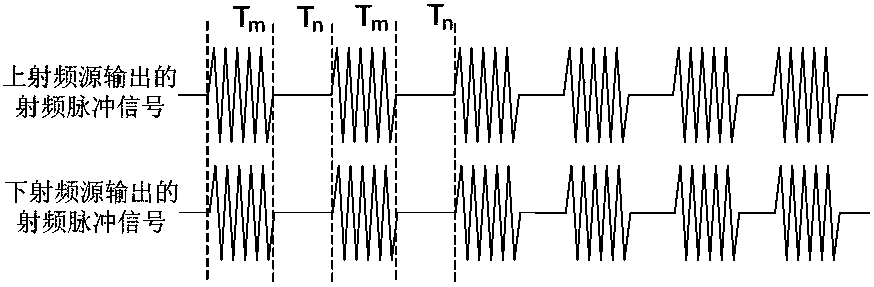

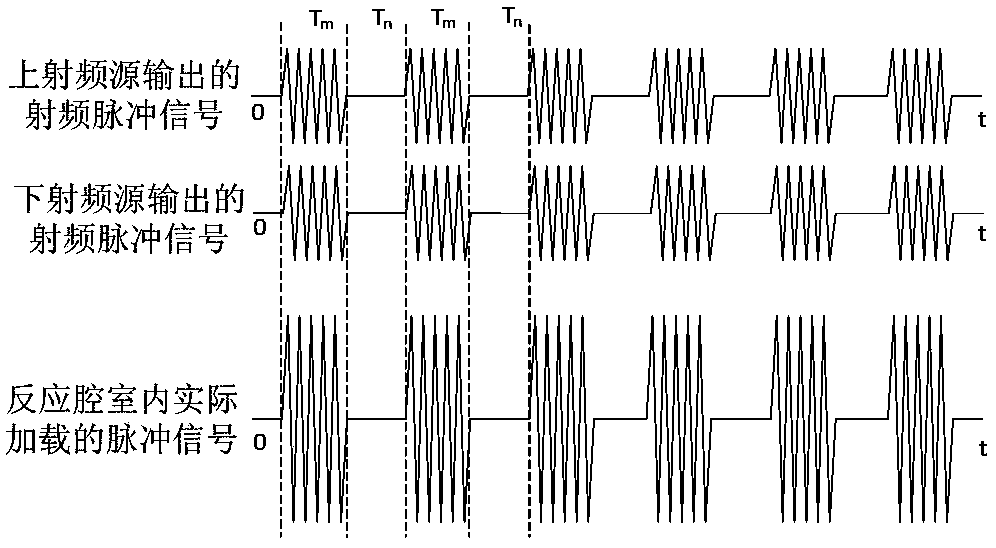

[0041] This embodiment provides a plasma generation method, comprising: the upper radio frequency source outputs a main pulse signal for exciting the process gas in the reaction chamber to form plasma, and during the closing phase of the main pulse signal, the upper radio frequency source outputs one or more Auxiliary pulse signal, the auxiliary pulse signal can maintain the plasma in the reaction chamber in an ignition state during the off stage of the main pulse signal.

[0042] During the closing phase of the main pulse signal, the upper radio frequency source outputs one or more auxiliary pulse signals, and the plasma in the reaction chamber is kept in a glowing state during the closing phase of the main pulse signal through the auxiliary pulse signal, which can prevent the reaction chamber from being Plasma extinction in the off-phase of the main pulse signal caused by insufficient main pulse power loaded, thereby achieving stable generation of plasma in the reaction chamb...

Embodiment 2

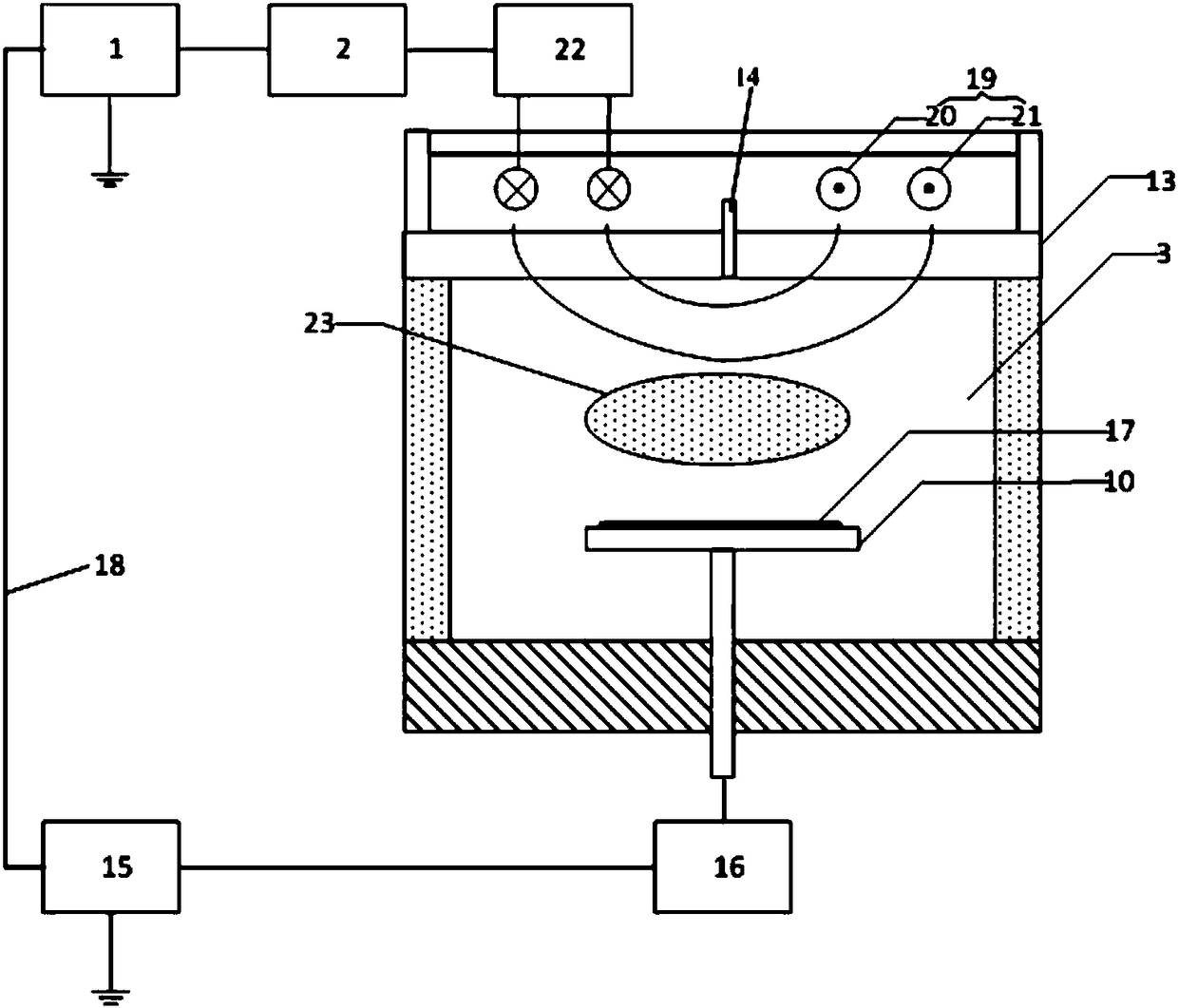

[0056] Based on the plasma generation method in Embodiment 1, this embodiment provides a plasma generation device, such as Figure 7 As shown, including the upper radio frequency source 1, the upper radio frequency source 1 can output a main pulse signal to excite the process gas in the reaction chamber 3 to form a plasma 23, and the upper radio frequency source 1 can also output one or A plurality of auxiliary pulse signals, the auxiliary pulse signals can maintain the plasma 23 in the reaction chamber 3 in an ignition state during the off phase of the main pulse signal.

[0057]In this embodiment, the upper radio frequency source 1 includes a main radio frequency source 11, the main radio frequency source 11 is connected to the main coil 4 at the top of the reaction chamber 3 through the first matcher 2, the main radio frequency source 11 can output the main pulse signal, and the upper radio frequency source 1 Also comprise auxiliary radio frequency source 12, auxiliary radi...

Embodiment 3

[0069] Based on the plasma generation method provided in Embodiment 1, this embodiment provides a plasma generation device, the difference from Embodiment 2 is that, as Figure 9 As shown, the upper radio frequency source 1 only includes the main radio frequency source 11, that is, the plasma generating device in this embodiment is only provided with the main radio frequency source 11, and no auxiliary radio frequency source is provided. The main radio frequency source 11 can output a main pulse signal, and output one or more auxiliary pulse signals during the off phase of the main pulse signal.

[0070] Correspondingly, the plasma generating device also includes a first control switch 8, the first control switch 8 is connected between the output end of the main radio frequency source 11 and the input end of the first matcher 2; the first control switch 8 is turned on or off , to control the main radio frequency source 11 to output or stop outputting the main pulse signal or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com