Tangerine whole-fruit superfine powder and preparation method thereof

A technology of ultrafine powder and ultrafine pulverization, which is applied in food ultrasonic treatment, function of food ingredients, food drying, etc., can solve the problems of lack of deep processing of whole citrus fruits, low retention rate of functional components, poor water solubility of whole fruit powder, etc., to achieve Rich in functional active ingredients, bright in color, and retains nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

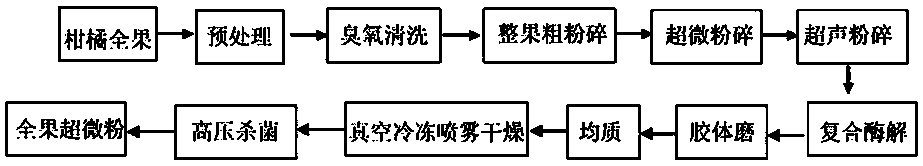

[0030]A kind of preparation method of citrus whole fruit superfine powder of the present invention, technological process is as figure 1 shown, including the following steps:

[0031] (1) Raw material pretreatment: select bright red sweet oranges that are fresh, rich in aroma and high in sugar content, remove rotten oranges, remove citrus stalks, clean soil and other impurities.

[0032] (2) Degradation and sterilization of pesticide residues: Put the pretreated citrus in an ozone tank for high-concentration ozone cleaning, the ozone concentration is 5mg / L-15mg / L, and the treatment time is 15min-40min to remove pesticide residues from citrus peels. Degradation and sterilization.

[0033] (3) Pulp micronization: transport the citrus degraded and sterilized by pesticide residues into the GFM-FC-3 fruit and vegetable crusher for crushing twice for coarse crushing at a speed of 1500r / min to obtain a mixture of citrus juice residue, citrus juice residue The particle size of the p...

Embodiment 2

[0041] A kind of preparation method of citrus whole fruit superfine powder of the present invention, technological process is as figure 1 shown, including the following steps:

[0042] (1) Pretreatment of raw materials: select fresh Century Red Tangerines, and remove rotten raw materials and soil and other impurities.

[0043] (2) Degradation and sterilization of pesticide residues: Put the pretreated citrus in an ozone pool for high-concentration ozone cleaning to degrade and sterilize the citrus peels with pesticide residues.

[0044] (3) Pulp micronization: transport the citrus degraded and sterilized by pesticide residues into the GFM-FC-3 fruit and vegetable crusher for coarse crushing for 3 times at a speed of 1500r / min to obtain a mixture of citrus juice residue and a mixture of citrus juice residue The pulp and skin dregs in the fruit have a particle size of 3mm to 5mm. The coarsely crushed citrus juice residue mixture is ultrafinely pulverized 4 times with a QDGP-11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com