Polyethersulfone temperature-sensing catalytic membrane and preparation method and application thereof

A technology of polyethersulfone membrane and catalytic membrane, applied in the field of temperature-sensitive catalytic membrane, can solve the problems of low utilization rate of catalyst, low catalytic rate of catalytic membrane, small catalytic space, etc., so as to improve wastewater treatment efficiency, efficient and intelligent catalytic process, The effect of high pollutant conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

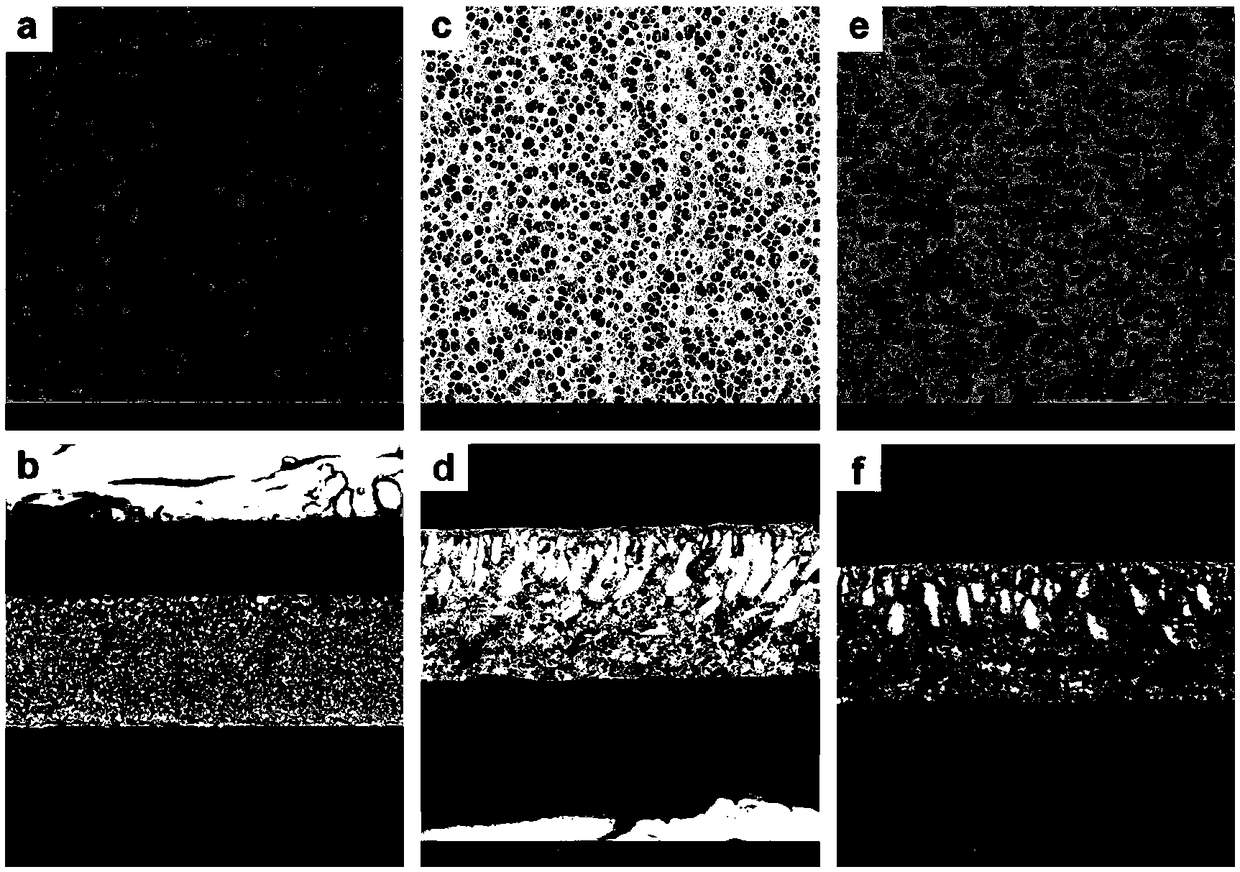

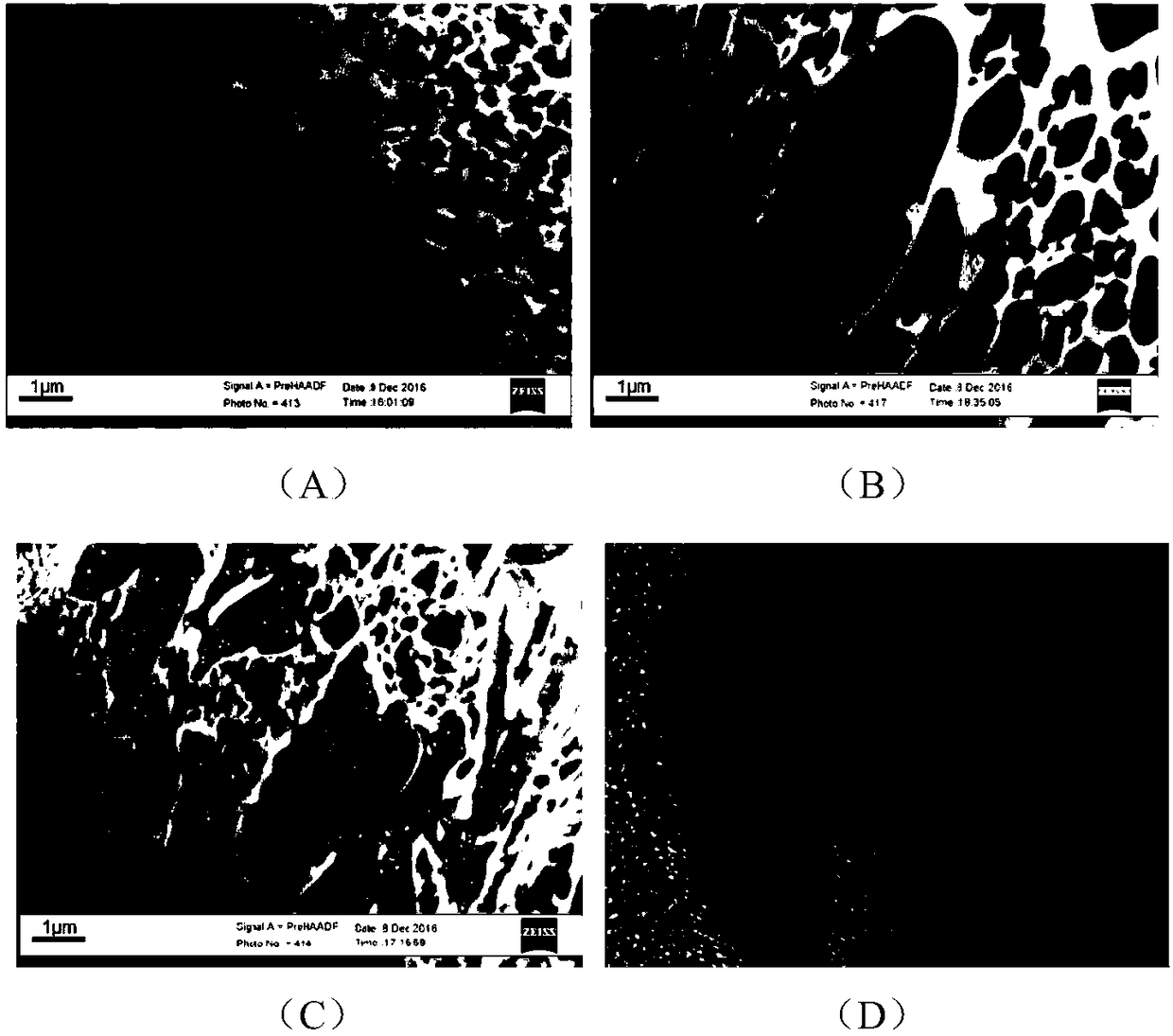

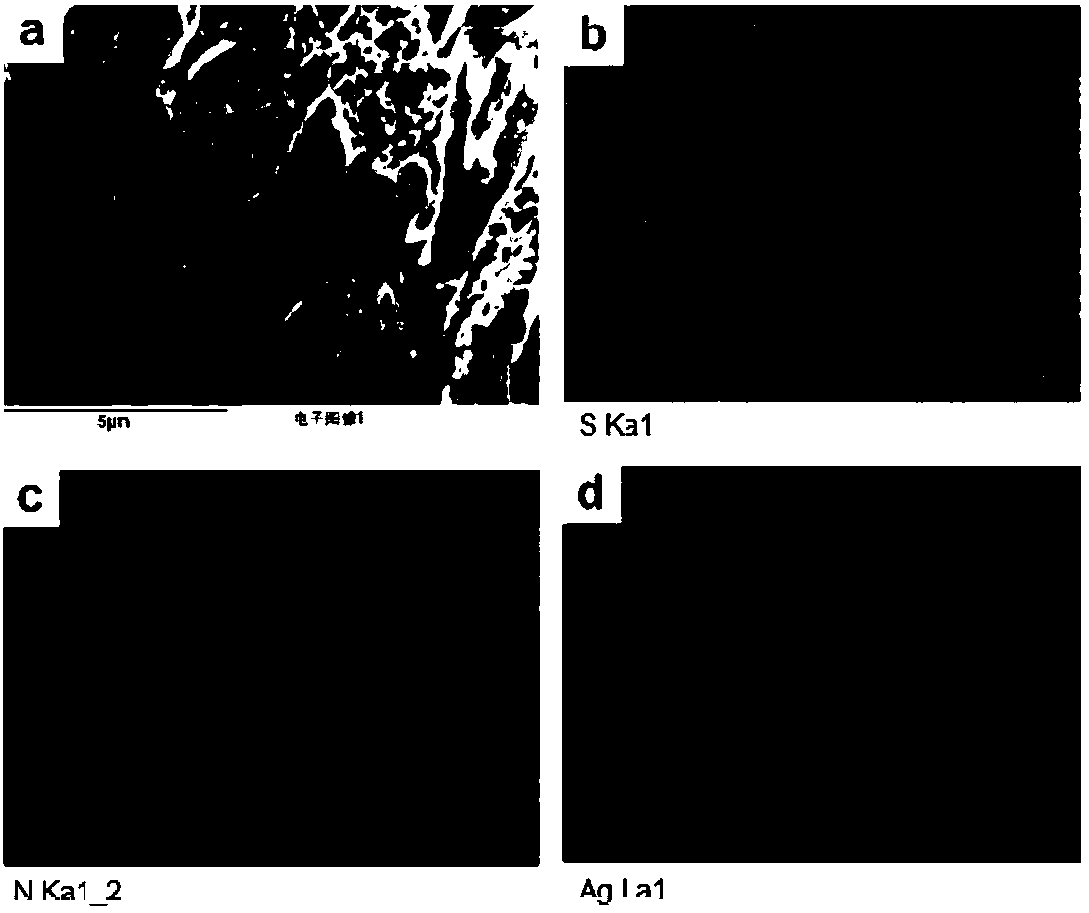

[0044] In this example, the preparation method of the polyethersulfone temperature-sensitive catalytic membrane is as follows:

[0045] (1) Take N-isopropylacrylamide as monomer, N,N-methylenebisacrylamide as crosslinking agent, and potassium persulfate as initiator, add the above substances and deionized water into a flat-bottomed flask and stir evenly , pass through nitrogen to remove oxygen for about 20 minutes, seal the single-necked flask, and react at 70°C for 4 hours under stirring, filter the resulting reaction solution to remove agglomerated microspheres and large particles, and then centrifuge the filtrate at 8000r / Centrifuge at a speed of 1 min for 3 times, each time for 20 min. After the centrifugation, remove the supernatant and transfer it to a plastic beaker, freeze it with liquid nitrogen, and freeze-dry it at -55 °C and a pressure of less than 100 Pa for 48 h to obtain polyN- Isopropylacrylamide microsphere dry powder (PNIPAM microsphere dry powder), take out...

Embodiment 2

[0066] In this example, the preparation method of the polyethersulfone temperature-sensitive catalytic membrane is as follows:

[0067] (1) Take N-isopropylacrylamide as monomer, N,N-methylenebisacrylamide as crosslinking agent, and potassium persulfate as initiator, add the above substances and deionized water into a flat-bottomed flask and stir evenly , pass through nitrogen to remove oxygen for about 30min, seal the single-necked flask, and react at 65°C for 7h under stirring, filter the resulting reaction solution to remove agglomerated microspheres and large particles, and then centrifuge the filtrate at 6000r / Centrifuge for 3 times at a speed of 1 min, each time for 20 min. After the centrifugation, remove the supernatant and transfer it to a plastic beaker, freeze it with liquid nitrogen, and freeze-dry it at -55 ° C and a pressure of less than 100 Pa for 48 h to obtain PNIPAM microspheres. Dry powder, take it out and store it in a dry cabinet for later use; the ratio ...

Embodiment 3

[0071] In this example, the preparation method of the polyethersulfone temperature-sensitive catalytic membrane is as follows:

[0072](1) Take N-isopropylacrylamide as monomer, N,N-methylenebisacrylamide as crosslinking agent, and potassium persulfate as initiator, add the above substances and deionized water into a flat-bottomed flask and stir evenly , pass through nitrogen to remove oxygen for about 40min, seal the single-necked flask, and react at 75°C for 5h under stirring, filter the resulting reaction solution to remove agglomerated microspheres and large particles, and then centrifuge the filtrate at 9000r / Centrifuge at a speed of 4 minutes, 20 minutes each time. After the centrifugation, remove the supernatant and transfer it to a plastic beaker, freeze it with liquid nitrogen, and freeze-dry it at -55°C and a pressure of less than 100Pa for 48 hours to obtain PNIPAM microspheres. Dry powder, take it out and store it in a dry cabinet for later use; the ratio of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com