Preparation method and application for bismuth titanate nanosheet

A technology of nanosheets and bismuth titanate, applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc. Removal and other problems, to achieve the effect of short processing flow, good visible light response ability, and regular powder shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

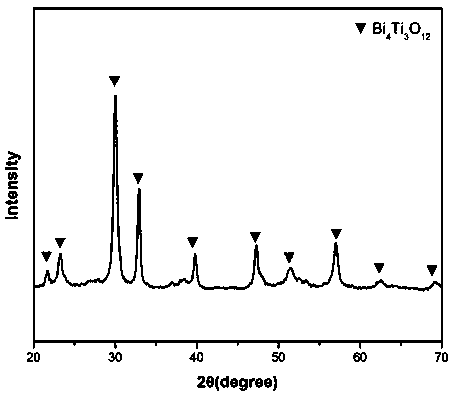

[0022] (1) Bi 4 Ti 3 o 12 Catalyst preparation

[0023] Add 0.5g of P25 into 1L of deionized water, ultrasonically disperse for 30min (ultrasonic frequency is 3kHz), and obtain precursor solution A.

[0024] 0.02mol Bi(NO 3 ) 3 ·5H 2 O was added to 250ml of 40% glacial acetic acid by volume, stirred at room temperature for 10min at a stirring speed of 100r / min to obtain a transparent and clear precursor solution B.

[0025] Add solution B dropwise to solution A, stir continuously for 6 hours and then let it stand still; the powder obtained after suction filtration, cleaning and drying is calcined in a tube furnace at 550°C for 5 hours to obtain nanosheet Bi 4 Ti 3 o 12 .

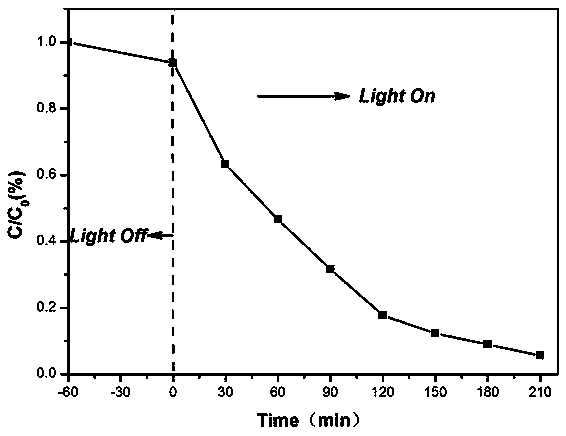

[0026] (2) Bi 4 Ti 3 o 12 Catalyst degradation RhB experiment:

[0027] Add 200mg of catalyst to 200ml of RhB solution with a concentration of 10ppm, ultrasonically disperse in the dark for 10min, transfer the reaction solution to a photocatalytic box and stir for 60min to reach adsorption-desor...

Embodiment 2

[0034] (1) Bi 4 Ti 3 o 12 Catalyst preparation

[0035] Add 0.65g of P25 into 2.95L of deionized water, and ultrasonically disperse for 40min (ultrasonic frequency is 30kHz) to obtain precursor solution A.

[0036] 0.025mol Bi(NO 3 ) 3 ·5H 2 O was added to 50ml of glacial acetic acid with a concentration of 60% by volume, and stirred at room temperature for 10min at a stirring speed of 200r / min to obtain a transparent and clear precursor solution B.

[0037]Add solution B dropwise to solution A, stir continuously for 8 hours and then let it stand still; the powder obtained after suction filtration, cleaning and drying is calcined in a tube furnace at 600°C for 3.5 hours to obtain nanosheet Bi 4 Ti 3 o 12 .

[0038] (2) Bi 4 Ti 3 o 12 Catalyst degradation RhB experiment

[0039] Add 200mg of catalyst to 200ml of RhB solution with a concentration of 10ppm, ultrasonically disperse in the dark for 10min, transfer the reaction solution to a photocatalytic box and stir ...

Embodiment 3

[0043] (1) Bi 4 Ti 3 o 12 Catalyst preparation

[0044] Add 0.8g of P25 into 2.95L of deionized water, and ultrasonically disperse for 45min (ultrasonic frequency is 10kHz) to obtain precursor solution A.

[0045] 0.03mol Bi(NO 3 ) 3 ·5H 2 O was added to 50ml of glacial acetic acid with a concentration of 70% by volume, stirred at room temperature for 15min at a stirring speed of 300r / min, and a transparent and clear precursor solution B was obtained.

[0046] Add solution B dropwise to solution A, stir continuously for 12 hours and then let it stand still; the powder obtained after suction filtration, cleaning and drying is calcined in a tube furnace at 650°C for 2 hours to obtain nanosheet Bi 4 Ti 3 o 12 .

[0047] (2) Bi 4 Ti 3 o 12 Catalyst degradation RhB experiment

[0048] Add 200mg of catalyst to 200ml of RhB solution with a concentration of 10ppm, ultrasonically disperse in the dark for 10min, transfer the reaction solution to a photocatalytic box and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com