High-strength dual-responsiveness nano-composite double network hydrogel and preparation method thereof

A nano-composite and hydrogel technology, applied in the field of polymer materials, can solve the problems of complex hydrogel conditions such as harsh conditions and complex processes, and achieve the effect of high mechanical strength and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

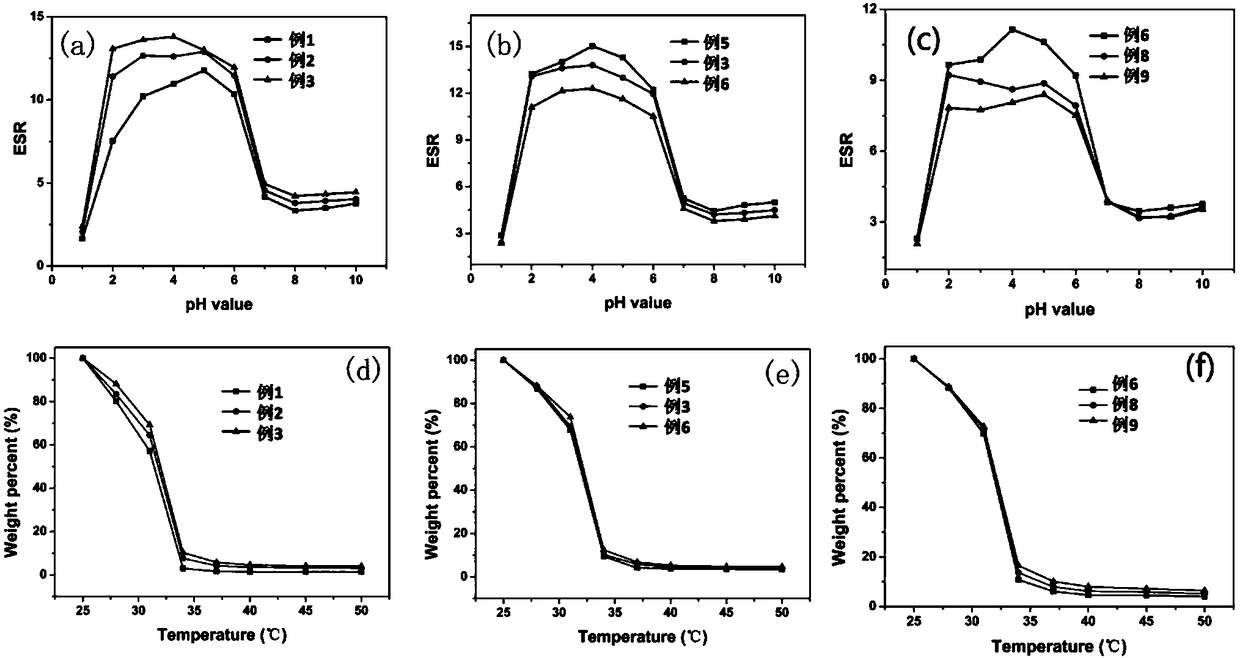

Examples

Embodiment 1

[0037] (1) Add 0.04g clay clay to 2.7mL deionized water, stir at 300rpm for 4h, dissolve evenly, then add 0.3g recrystallized NIPAM, 2.5mg photoinitiator 2959, 300μL genipin GP aqueous solution (1.5 mg / ml) and 3mg carboxymethyl chitosan CMCTs, continue to stir with 300rpm rotating speed for 2h, mix well, obtain NIPAM / clay / GP / CMCTs dispersion liquid; Transfer to the transparent plastic tube mold that diameter is 4.65mm, length is 60mm , and then use a power of 180W to put in a circulating water vacuum pump for 10min and fill it with high-purity nitrogen, repeat 3 times, then seal the other end of the plastic tube, and react in a water bath at room temperature for 20h to obtain a hydrogel of GP crosslinked CMCTs.

[0038](2) irradiate the hydrogel obtained in step (1) with a wavelength of 365nm and a power of 8W in a water bath at room temperature for 2h, rotate the sample by 90 degrees every 0.5h, and the distance from the lamp tube to the sample is 10mm, A high-strength dual-r...

Embodiment 2

[0040] (1) Add 0.04g clay clay to 2.7mL deionized water, stir at 300rpm for 4h, dissolve evenly, then add 0.3g recrystallized NIPAM, 2.5mg photoinitiator 2959, 300μL genipin GP aqueous solution (1.5 mg / ml) and 9mg carboxymethyl chitosan CMCTs, continue to stir at 300rpm for 2h, mix well to obtain NIPAM / clay / GP / CMCTs dispersion; transfer to a transparent plastic tube mold with a diameter of 4.65mm and a length of 60mm , and then use a power of 180W to put in a circulating water vacuum pump for 10min and fill it with high-purity nitrogen, repeat 3 times, then seal the other end of the plastic tube, and react in a water bath at room temperature for 20h to obtain a hydrogel of GP cross-linked CMCTs.

[0041] (2) irradiate the hydrogel obtained in step (1) with a wavelength of 365nm and a power of 8W in a water bath at room temperature for 2h, rotate the sample by 90 degrees every 0.5h, and the distance from the lamp tube to the sample is 10mm, A high-strength dual-responsive nanoc...

Embodiment 3

[0043] (1) Add 0.04g clay clay to 2.7mL deionized water, stir at 300rpm for 4h, dissolve evenly, then add 0.3g recrystallized NIPAM, 2.5mg photoinitiator 2959, 300μL genipin GP aqueous solution (1.5 mg / ml) and 15mg carboxymethyl chitosan CMCTs, continue to stir at 300rpm for 2h, mix well to obtain NIPAM / clay / GP / CMCTs dispersion; transfer to a transparent plastic tube mold with a diameter of 4.65mm and a length of 60mm , and then use a power of 180W to put in a circulating water vacuum pump for 10min and fill it with high-purity nitrogen, repeat 3 times, then seal the other end of the plastic tube, and react in a water bath at room temperature for 20h to obtain a hydrogel of GP cross-linked CMCTs.

[0044] (2) irradiate the hydrogel obtained in step (1) with a wavelength of 365nm and a power of 8W in a water bath at room temperature for 2h, rotate the sample by 90 degrees every 0.5h, and the distance from the lamp tube to the sample is 10mm, A high-strength dual-responsive nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com