A kind of polymer emulsion waterproof coating and preparation method thereof

A technology for polymer emulsions and waterproof coatings, applied in antifouling/underwater coatings, radiation-absorbing coatings, coatings, etc., can solve the problem of separation of waterproof coating filling materials and film-forming materials, anti-fouling performance (poor self-cleaning property) , Low strength of mechanical properties, etc., to achieve the effect of improving stability and mechanical properties, strong UV resistance, and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 24 parts of polyvinyl acetate-ethylene copolymer emulsion, 31.5 parts of polyacrylate emulsion, 8 parts of water, 16.7 parts of white carbon black, 4.5 parts of plasticizer dioctyl phthalate, 0.2 parts of LX-7 dispersant into the reaction vessel 0.1 part of wetting agent polyethylene glycol, 1 part of antifreeze propylene glycol, 0.5 part of PB2706 defoamer, at room temperature (20-28 ℃), at the speed of 800-1500 rpm, stirring for 15 minutes, and then Add 7.5 parts of heavy calcium carbonate, 3 parts of titanium dioxide, and 3 parts of barium sulfate, and stir for 20 minutes under vacuum-0.1MPa conditions, then discharge and pack. Product performance test results are shown in Table 1:

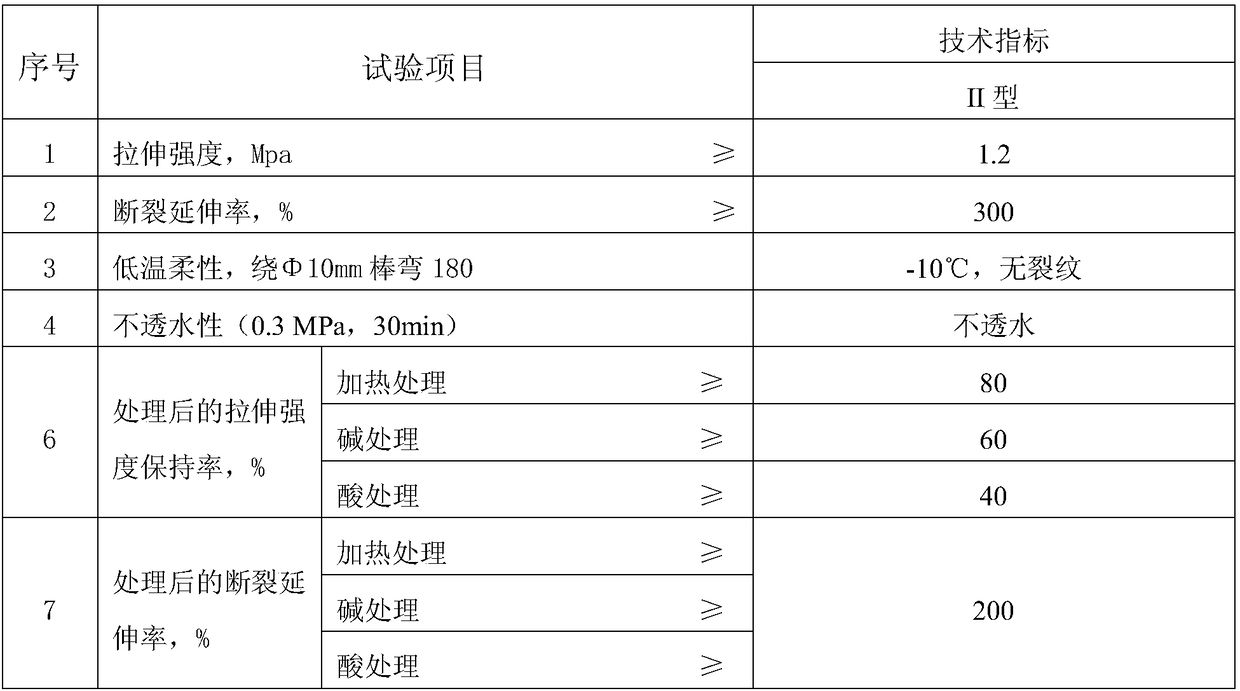

[0022] Table 1-performance test results of Example 1 of the present invention

[0023] Test items

Embodiment 2

[0025] Add 20 parts of polyvinyl acetate-ethylene copolymer emulsion, 32 parts of polyacrylate emulsion, 9.5 parts of water, 20.5 parts of white carbon black, 4 parts of plasticizer dibutyl phthalate, 0.2 parts of dispersant (PS5000) in the reaction vessel 1 part, 0.1 part of wetting agent polyethylene glycol, 1 part of antifreeze propylene glycol, 1 part of defoamer (DP602), at room temperature (20-28 ℃), at the speed of 800-1500 rpm, stirring for 15 minutes, Then add 7 parts of heavy calcium carbonate, 2.35 parts each of titanium dioxide and barium sulfate, and stir for 20 minutes under the condition of vacuum -0.1MPa, then discharge and pack. Product performance test results are shown in Table 2:

[0026] Table 2-performance test results of Example 2 of the present invention

[0027] Test items

Embodiment 3

[0029] In the reaction vessel, add 16 parts of polyvinyl acetate-ethylene copolymer emulsion, 32 parts of polyacrylate emulsion, 9 parts of water, 22 parts of white carbon black, 4.5 parts of plasticizer chlorinated paraffin, 0.2 part of dispersant sodium hexametaphosphate, Wet agent polyethylene glycol 0.1 part, antifreeze agent propylene glycol 1 part, defoamer (DP628) 1 part, at room temperature (20-28 ℃), at the speed of 800-1500 rpm, stir for 15 minutes, then add 8.2 parts of heavy calcium carbonate, 3 parts of titanium dioxide and 3 parts of barium sulfate each, under the condition of vacuum -0.1MPa, stir for 20 minutes and then discharge and pack. Product performance test results are shown in Table 3:

[0030] Table 3-performance test result of embodiment 3 of the present invention

[0031] Test items

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com