High-temperature-resistant phenolic carrier glue film and preparation method thereof

A technology of high temperature resistance and phenolic glue, which is applied in the direction of adhesives, epoxy resin glue, polymer adhesive additives, etc., can solve the problems of insufficient high temperature resistance, poor toughness of phenolic film, poor bonding strength, etc., and achieve improvement Effect of heat resistance, good toughness and adhesive performance, excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Weigh 100 grams of boron phenolic resin, 30 grams of carboxyl-terminated liquid nitrile rubber (CTBN), 100 grams of ethanol solvent. Pour the materials into a high-speed mixer and stir fully at room temperature until the materials dissolve.

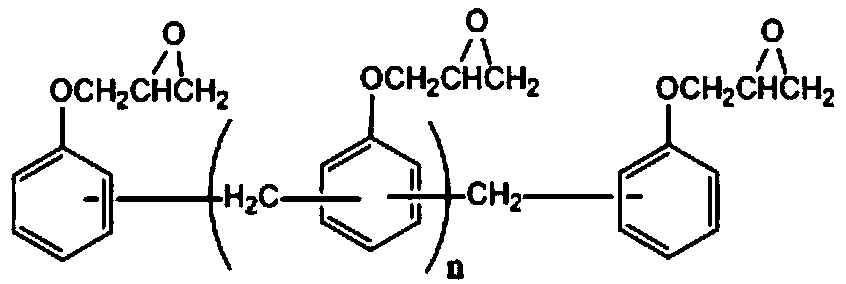

[0029] 2. Add 50 grams of F-51 epoxy resin and 5 grams of propylene oxide propylene ether into the above solution, stir well until the mixture is uniform, and obtain a phenolic / rubber / epoxy ternary system glue.

[0030] 3. Heat the glue solution obtained above to 60°C, and coat it on the glass fiber mesh cloth through a coating machine. After the glue solution is completely impregnated, put it in a 60°C oven for 1 hour to remove the ethanol solvent, and obtain a 0.5mm thickness High temperature resistant phenolic carrier film.

[0031] The adhesive film prepared above was used for the bonding of stainless steel, and samples were prepared according to GB7124-1986, and cured at 180°C for 3 hours to obtain test samples for tensile ...

Embodiment 2

[0033] 1. Weigh 100 grams of boron phenolic resin, 10 grams of powdered nitrile rubber (NBR), and 100 grams of ethanol solvent. Pour the material into a high-speed mixer and stir well at room temperature until the material is dispersed.

[0034] 2. Add 50 grams of F-51 epoxy resin and 5 grams of propylene oxide propylene ether diluent to the above solution, stir well until the mixture is uniform, and obtain a phenolic / rubber / epoxy ternary system glue.

[0035] 3. Heat the glue solution obtained above to 60°C, and coat it on the glass fiber mesh cloth through a coating machine. After the glue solution is completely impregnated, put it in a 60°C oven for 1 hour to remove the ethanol solvent, and obtain a 0.5mm thickness High temperature resistant phenolic carrier film.

[0036] 4. Use the adhesive film prepared above for bonding stainless steel, prepare samples according to GB7124-1986, and cure at 180° C. for 3 hours to obtain test samples for tensile shear strength. The meas...

Embodiment 3

[0038] 1. Weigh 100 grams of barium phenolic resin, 20 grams of powdered nitrile rubber (NBR), and 100 grams of ethanol solvent. Pour the material into a high-speed mixer and stir well at room temperature until the material is dispersed.

[0039] 2. Add 30 grams of F-51 epoxy resin and 5 grams of propylene oxide propylene ether diluent to the above solution, stir well until the mixture is uniform, and obtain a phenolic / rubber / epoxy ternary system glue.

[0040] 3. Heat the glue solution obtained above to 60°C, and coat it on the glass fiber mesh cloth through a coating machine. After the glue solution is completely impregnated, put it in a 60°C oven for 1 hour to remove the ethanol solvent, and obtain a 0.5mm thickness High temperature resistant phenolic carrier film.

[0041] 4. Use the adhesive film prepared above for bonding stainless steel, prepare samples according to GB7124-1986, and cure at 180° C. for 3 hours to obtain test samples for tensile shear strength. The mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com