Preparation method and application of cellulose-based nitrogen-doped fluorescent carbon quantum dots

A carbon quantum dot, cellulose-based technology, which is applied in the field of preparing nitrogen-doped fluorescent carbon quantum dots based on cellulose, can solve the problems of complex synthesis steps, non-renewable raw materials, expensive instruments and equipment, etc., so as to solve the problems of expensive raw materials and good biological Compatible, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

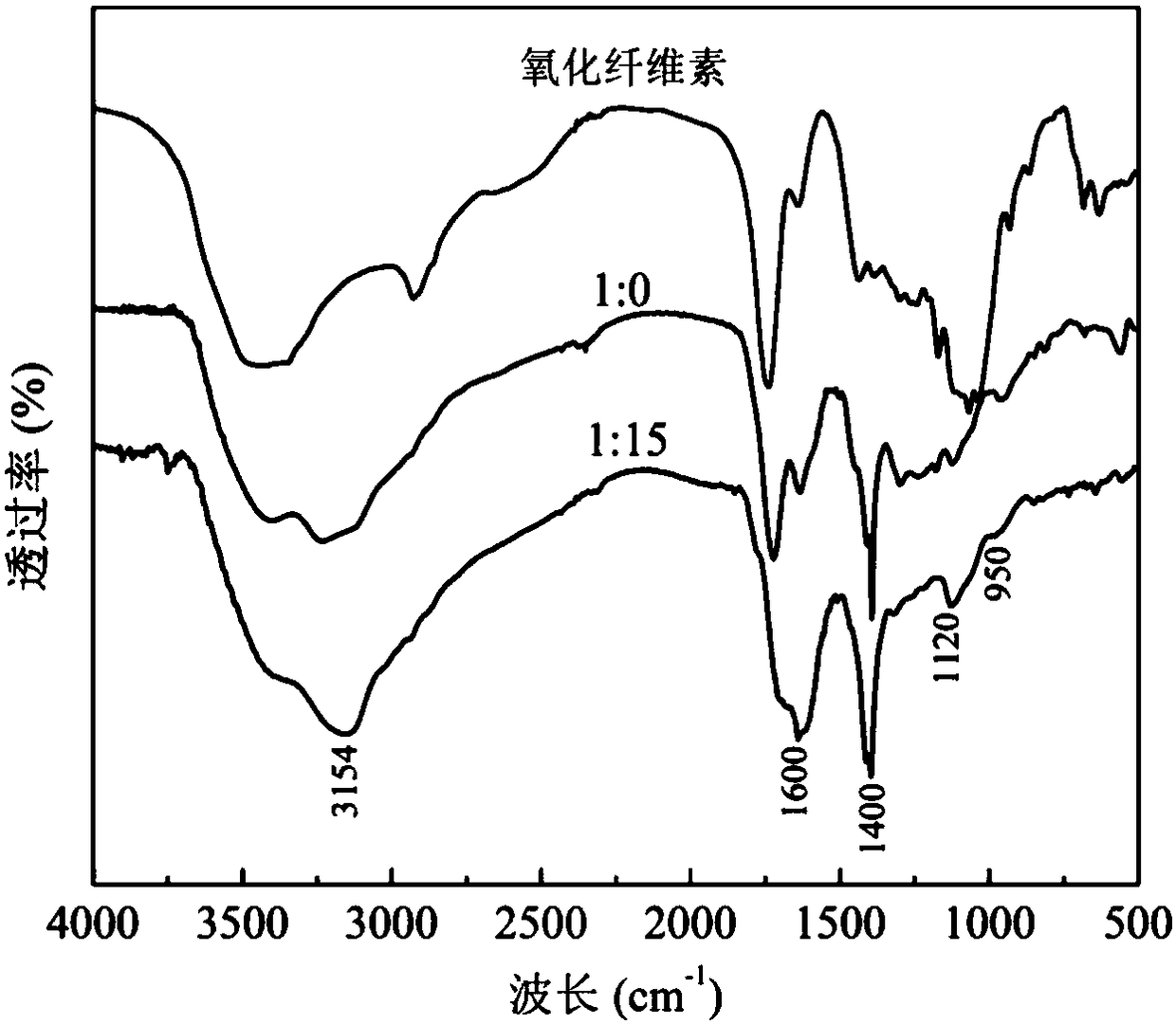

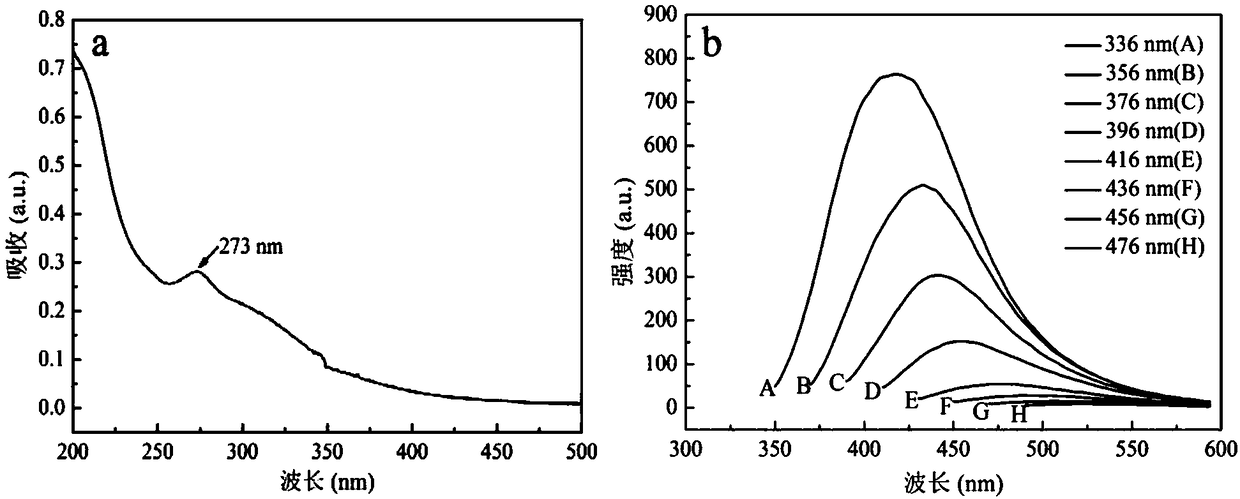

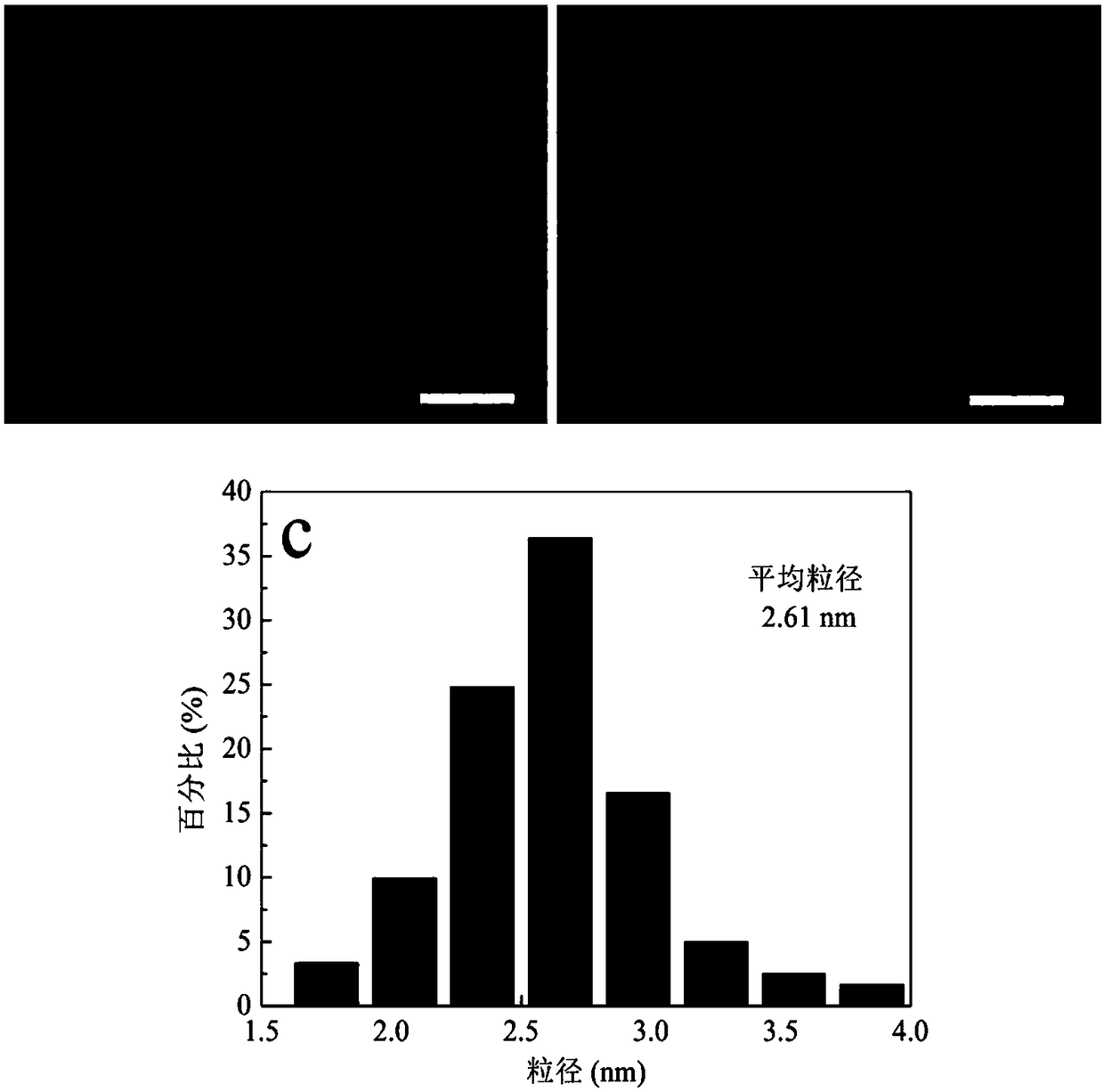

Embodiment 1

[0036] Weigh 10g of softwood dissolving pulp cellulose (polymerization degree 884, purchased from Shandong Bohai Industrial Co., Ltd.) and add to 140mL HNO 3 and H 3 PO 4 In the mixed solution (2:1, V / V), swell at room temperature for 30 minutes, and add 1.96g NaNO under the condition of mechanical stirring at 10000r / min 2, adjust the reaction temperature of the system to 65 °C and heat the reaction for 24 hours to obtain the crude oxidized cellulose product; after cooling to room temperature, place the above crude product in 140 mL of ultra-pure water for precipitation, and after standing for 30 min, at a speed of 12000 r / min Centrifuge for 30 minutes, wash repeatedly with 95% ethanol / water solution (2:1, V / V) until the pH of the filtrate is neutral, and dry the precipitate under vacuum at 50°C for 48 hours to obtain purified oxidized cellulose; The oxidized cellulose was dissolved in ultrapure water, and ultrasonic dispersion was performed for 1 hour under the condition th...

Embodiment 2

[0039] Weigh 10g of softwood dissolving pulp cellulose (polymerization degree 884, purchased from Shandong Bohai Industrial Co., Ltd.) and add to 140mL HNO 3 and H 3 PO 4 In the mixed solution (2:1, V / V), swell at room temperature for 30 minutes, and add 1.96g NaNO under the condition of mechanical stirring at 10000r / min 2 , adjust the reaction temperature of the system to 65 °C and heat the reaction for 24 hours to obtain the crude oxidized cellulose product; after cooling to room temperature, place the above crude product in 140 mL of ultra-pure water for precipitation, and after standing for 30 min, at a speed of 12000 r / min Centrifuge for 30 minutes, wash repeatedly with ethanol / water solution (2:1, V / V) until the pH of the filtrate is neutral, and dry the precipitate under vacuum at 50°C for 48 hours to obtain purified oxidized cellulose; then the purified oxidized cellulose The cellulose was dissolved in ultrapure water, and ultrasonically dispersed for 1 hour under th...

Embodiment 3

[0042] The difference from Example 2 is that the oxidized cellulose nanoparticles and NH in ammonia 3 The mass ratio is 1:2.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com