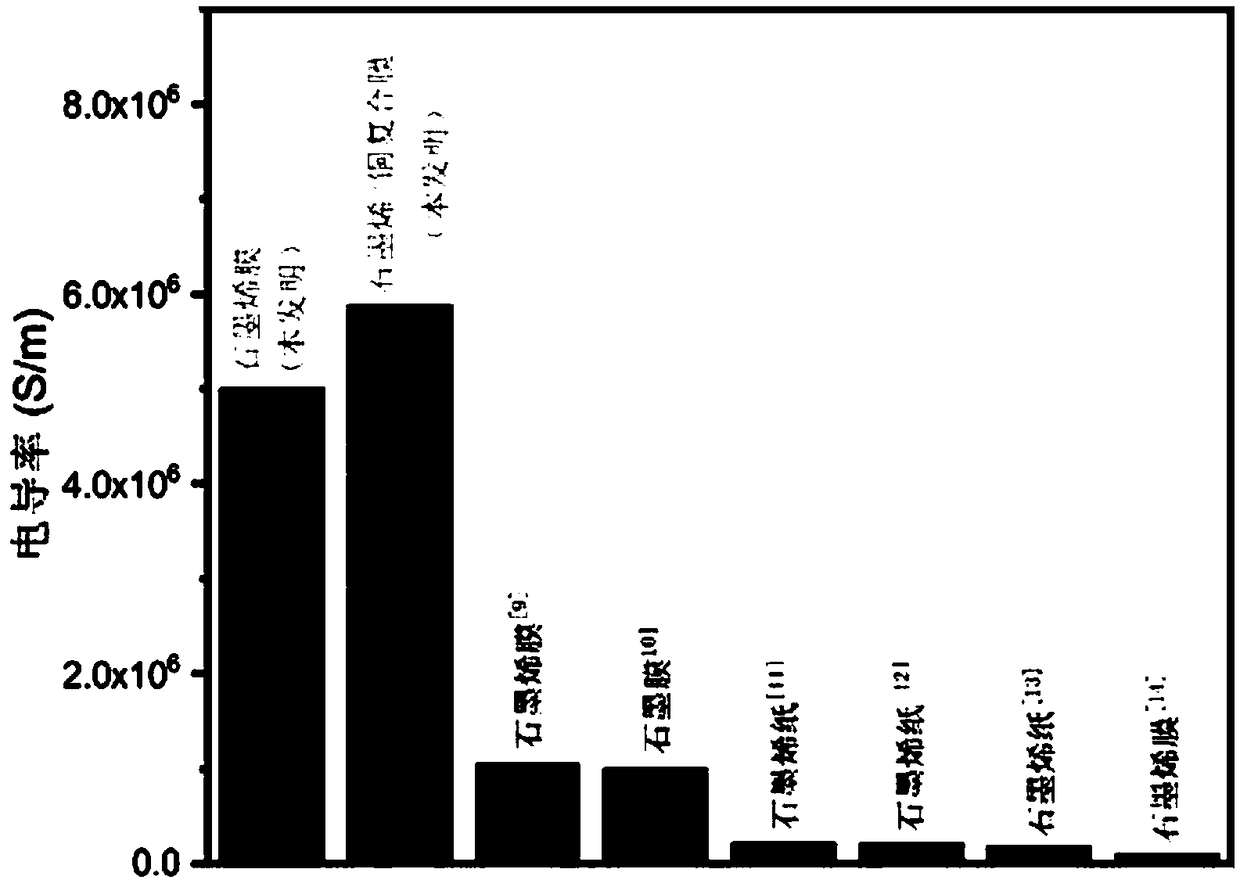

Large-flake graphite/metal heterojunction composite thin film for heat conducting and preparation method thereof

A technology of composite film and graphene film, which is applied in metal material coating process, superimposed layer plating, ion implantation plating, etc., can solve the problem of increasing interface thermal resistance and reduce interface thermal resistance and operating cost Low, thickness controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

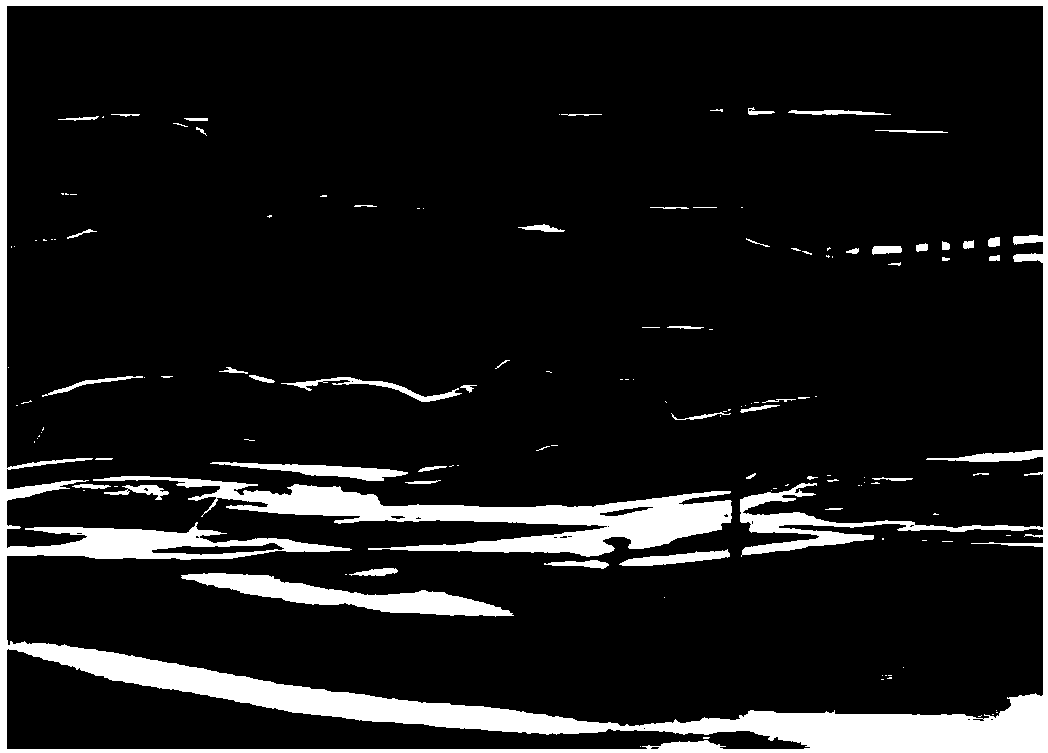

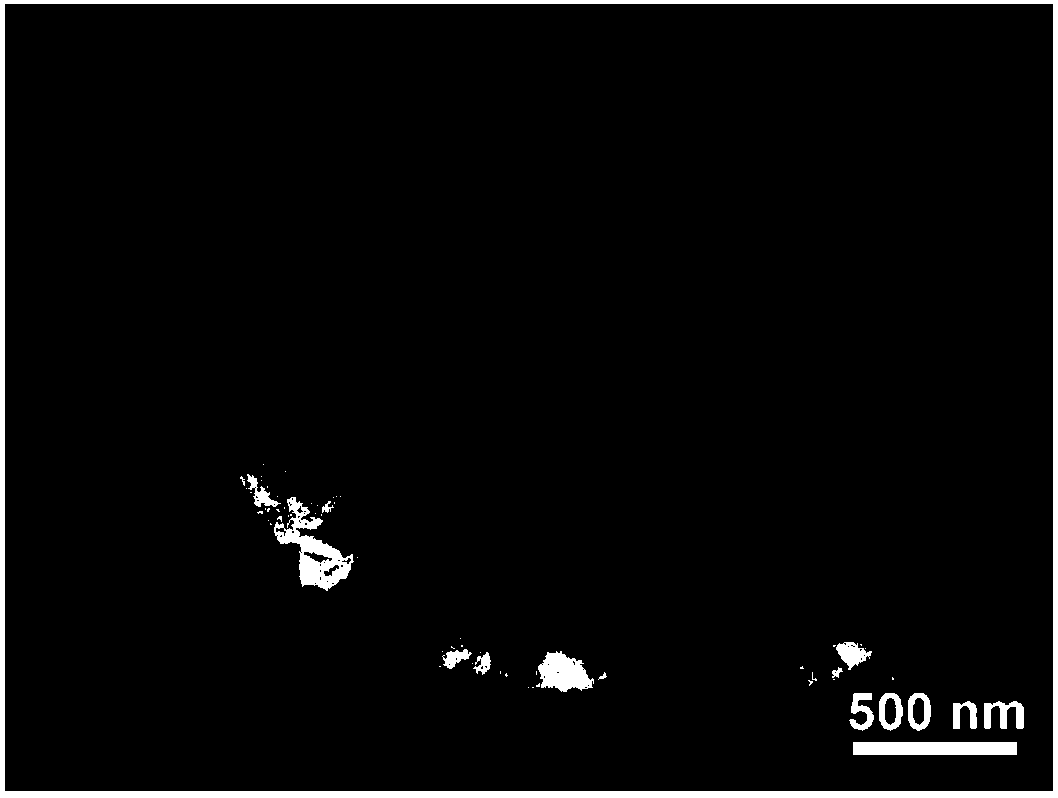

[0051] 1) Preparation of graphene membrane: the suspension of graphene oxide was diluted to a concentration of 2mg mL with ultrapure water with a resistivity of 18.25MΩ·cm -1 . After centrifugation at 5000rpm for 30min, take the bottom 30% volume solution and dilute to 2mg mL -1 , centrifuge again to enter the next cycle. Repeat the above operation 5 times, take the final 30% volume solution at the bottom, and concentrate it to 20mgmL -1 The large-scale graphene oxide dispersion liquid was scraped on the surface of copper foil, and vacuum-dried at 60°C for 24 hours to separate the large-scale graphene oxide film from the copper foil. The large-scale graphene film was synthesized by heating and rolling at 200°C.

[0052] 2) Preparation of flexible graphene film: place the large-scale graphene film after heating and rolling in a graphite high-temperature furnace, and first carbonize it at 1300 °C for 2 hours, with a heating rate of 5 °C min -1 , and then heat treated at 3000...

Embodiment 2

[0057] 1) Preparation of graphene membrane: the suspension of graphene oxide was diluted with ultrapure water with a resistivity of 18.25MΩ·cm to a concentration of 5mg mL -1 . After centrifugation at 6000rpm for 30min, take the bottom 20% volume solution and dilute to 5mg mL -1 , centrifuge again to enter the next cycle. Repeat the above operation 7 times, take the last 20% volume solution at the bottom, and concentrate it to 20mgmL -1 The large-scale graphene oxide dispersion liquid was scraped on the surface of copper foil, evaporated at room temperature for 24 hours, and the large-scale graphene oxide film was separated from the copper foil. The large-scale graphene film was synthesized by heating and rolling at 200°C.

[0058] 2) Preparation of flexible graphene film: place the heated and rolled graphene film in a graphite high-temperature furnace, and first carbonize it at 1000 °C for 2 hours, with a heating rate of 3 °C min -1 , and then heat treated at 3000°C for 1...

Embodiment 3

[0062] 1) Preparation of graphene membrane: the suspension of graphene oxide was diluted to a concentration of 2mg mL with ultrapure water with a resistivity of 18.25MΩ·cm -1 . After centrifugation at 3000rpm for 20min, take the bottom 30% volume solution and dilute to 2mg mL -1 , centrifuge again to enter the next cycle. Repeat the above operation 7 times, take the final 30% volume solution at the bottom, and concentrate it to 20mgmL -1 The large-scale graphene oxide dispersion liquid was scraped on the surface of copper foil, evaporated at room temperature for 24 hours, and the large-scale graphene oxide film was separated from the copper foil. The large-scale graphene film was synthesized by heating and rolling at 100°C.

[0063] 2) Preparation of flexible graphene film: place the heated and rolled graphene film in a graphite high-temperature furnace, and first carbonize it at 1300 °C for 2 hours, with a heating rate of 5 °C min -1 , and then heat treated at 2000°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com