Carbon-coated nickel cobalt selenide nano material with excellent water electrolysis performance and preparation method of carbon-coated nickel cobalt selenide nano material

A nanomaterial and carbon-coated technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of limited reserves, large-scale promotion and application, restrictions on large-scale commercial applications, high Overpotential and other issues, to achieve excellent catalytic activity, cheap raw materials, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

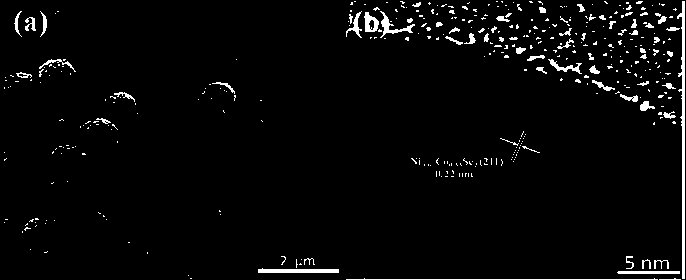

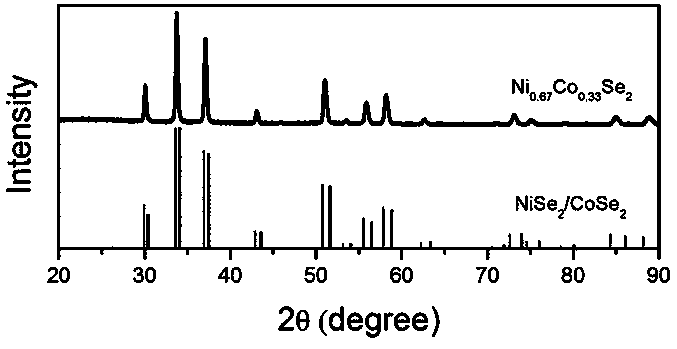

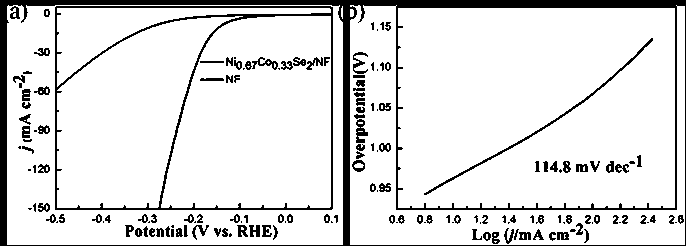

[0022] A carbon-coated nickel-cobalt selenide (Ni 0.67 co 0.33 Se 2 ) The preparation method of nanometer material comprises the following steps:

[0023] (1) 0.1746 g of Co(NO 3 ) 2 ·6H 2 O and 0.3489 g Ni(NO 3 ) 2 ·6H 2 O was added to a mixed solution of 9.375 milliliters of N,N-dimethylformamide (DMF) and 5.625 milliliters of ethanol, and then 0.36 grams of polyvinylpyrrolidone (PVP-K30) and 0.1995 grams of terephthalic acid were added, stirred and dissolved until Homogenize the solution, transfer the mixed solution to a hydrothermal kettle, and keep it at 120 degrees Celsius for 24 hours to synthesize the Co-Ni-MOFs material, take it out and cool it at room temperature.

[0024] (2) The Co-Ni-MOFs material obtained in step (1) was washed twice with deionized water and ethanol respectively, dried in vacuum at 80 degrees Celsius for 2 hours, cooled and ground into powder for later use.

[0025] (3) Weigh 0.1 g of the powder obtained in step (2) and 0.5 g of selenium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com