Preparation method of semiconductor composite material based on chemical vapor deposition

A chemical vapor deposition and composite material technology, applied in the field of metal semiconductor materials, can solve the problems of low repetition rate, unstable product structure and performance, and achieve the effects of simple preparation, promotion of hydrogen production efficiency and oxygen production efficiency, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

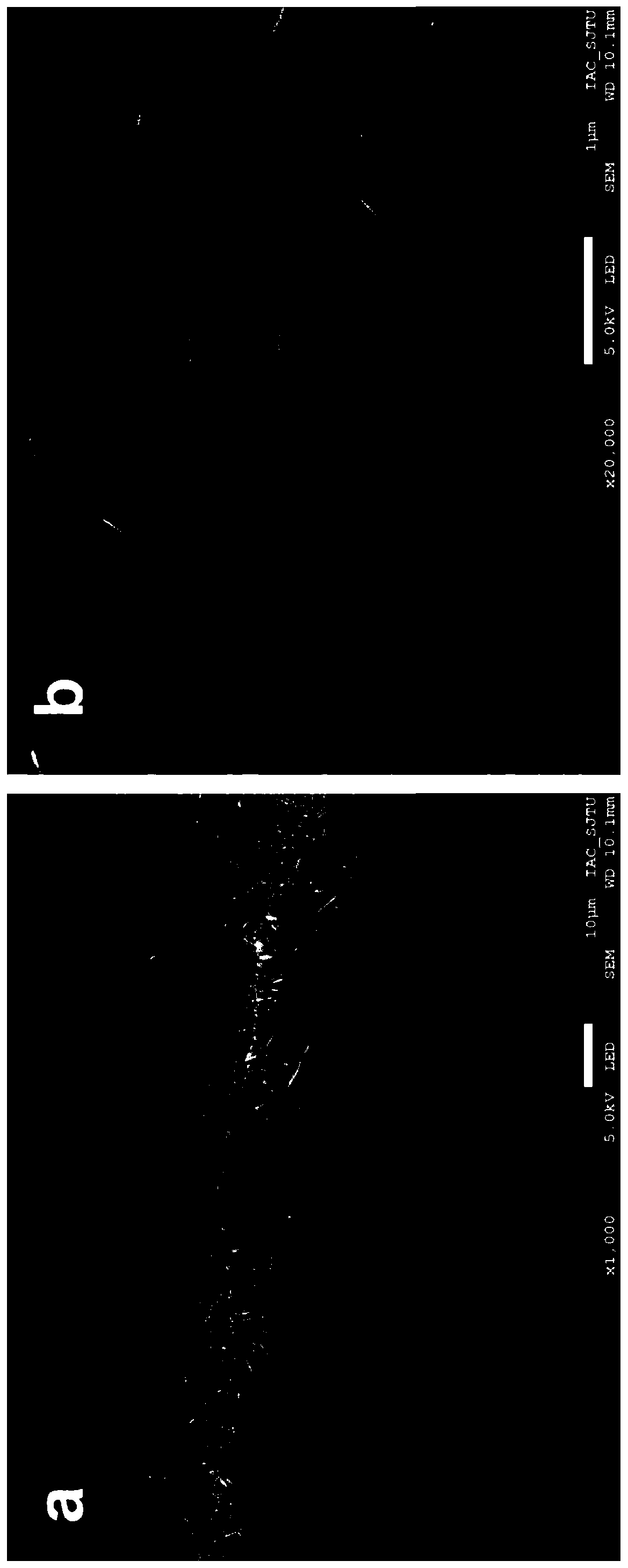

[0041] (1) Preparation of iron-nickel alloy-molybdenum sulfide

[0042]Wash the iron-nickel foam alloy (as the substrate) and silicon oxide with ethanol, acetone, 0.5M hydrochloric acid and deionized water in sequence, place the molybdenum oxide powder on the silicon oxide, and put it into a quartz boat, and put the iron-nickel foam alloy sheet Put it on the top of the quartz boat (that is, above the molybdenum oxide powder), put it into the tube furnace; put the sulfur powder in another quartz boat, also put it into the tube furnace, and put the sulfur powder and molybdenum oxide in the tube furnace Different temperature control areas, the sulfur powder is in the temperature area of the air flow inlet, and the molybdenum oxide is located in the middle area of the tube furnace. Firstly, nitrogen is passed into the tube furnace, air is exhausted, and then the temperature of the molybdenum oxide area is increased to 650 degrees Celsius, and then the temperature of the sulfur...

Embodiment 2

[0048] (1) Preparation of iron-nickel alloy-molybdenum selenide

[0049] Preparation of iron-nickel alloy-molybdenum selenide: the same as in Example 1, but the sulfur powder needs to be replaced with selenium powder.

[0050] (2) Iron-nickel alloy-molybdenum selenide for electrolysis of water

[0051] The hydrogen generation and oxygen generation reactions of iron-nickel alloy-molybdenum selenide: the same as in Example 1, but the reaction efficiency is different.

Embodiment 3

[0053] (1) Preparation of cobalt-molybdenum sulfide

[0054] Preparation of cobalt-molybdenum sulfide: the same as in Example 1, but the base material needs to be replaced with elemental cobalt flakes.

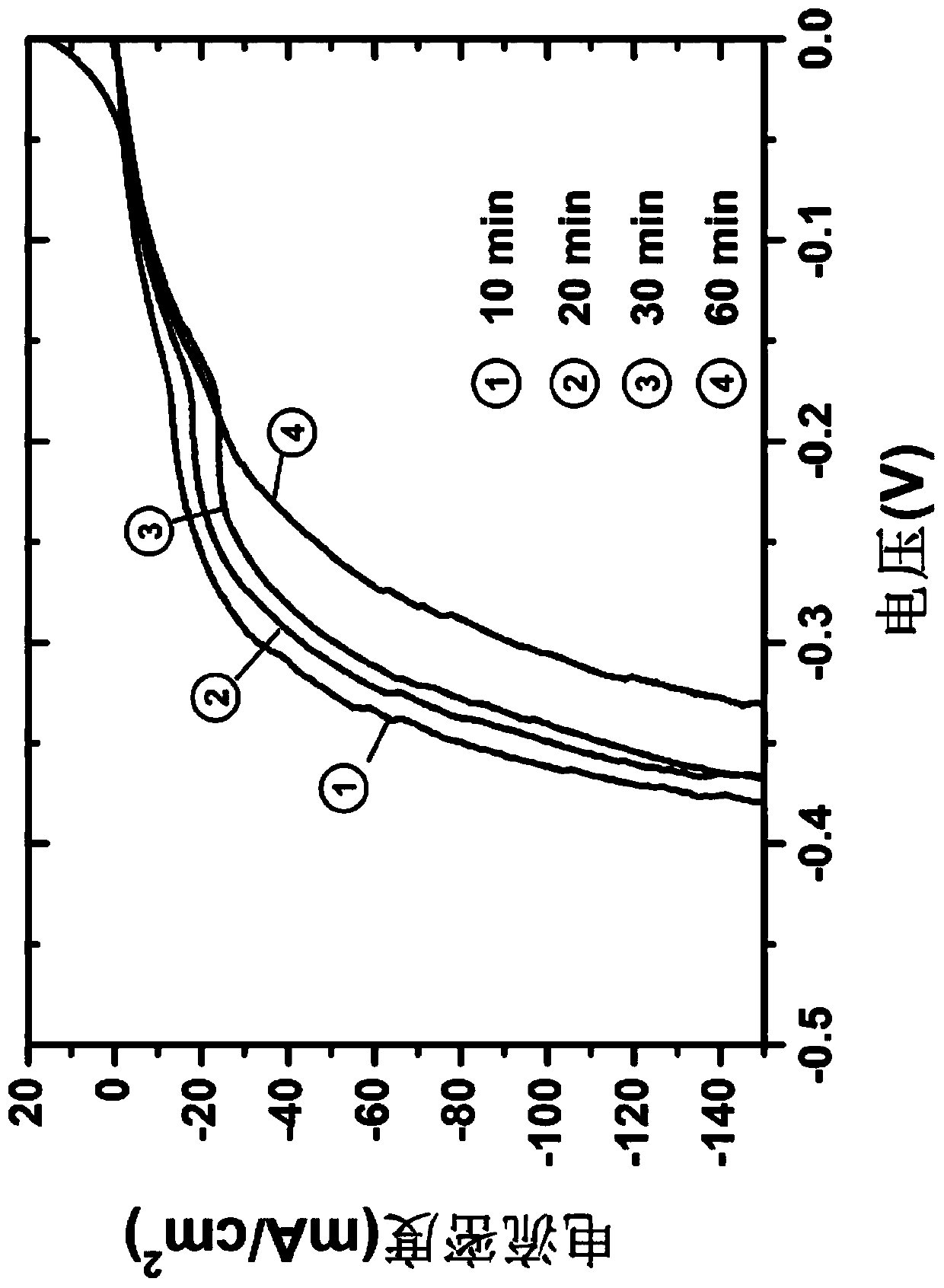

[0055] (2) Cobalt-molybdenum sulfide for electrolysis of water

[0056] Cobalt-molybdenum sulfide hydrogen generation and oxygen generation reaction: the same as Example 1, but the reaction efficiency is different. see Image 6 As shown, it can be seen that the cobalt-molybdenum sulfide prepared in this example has better moisture desorption and oxygen performance than ordinary pure Co flakes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com