Preparation method of space optical isolator and optical waveguide based on oxygen ion implantation of terbium gallium garnet optical waveguide

A technology of terbium gallium garnet and oxygen ion implantation, which is applied to optical waveguides, light guides, instruments, etc., to achieve the effect of improving coherent signal-to-noise ratio, reducing loss, and ensuring that the linear polarization direction remains unchanged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

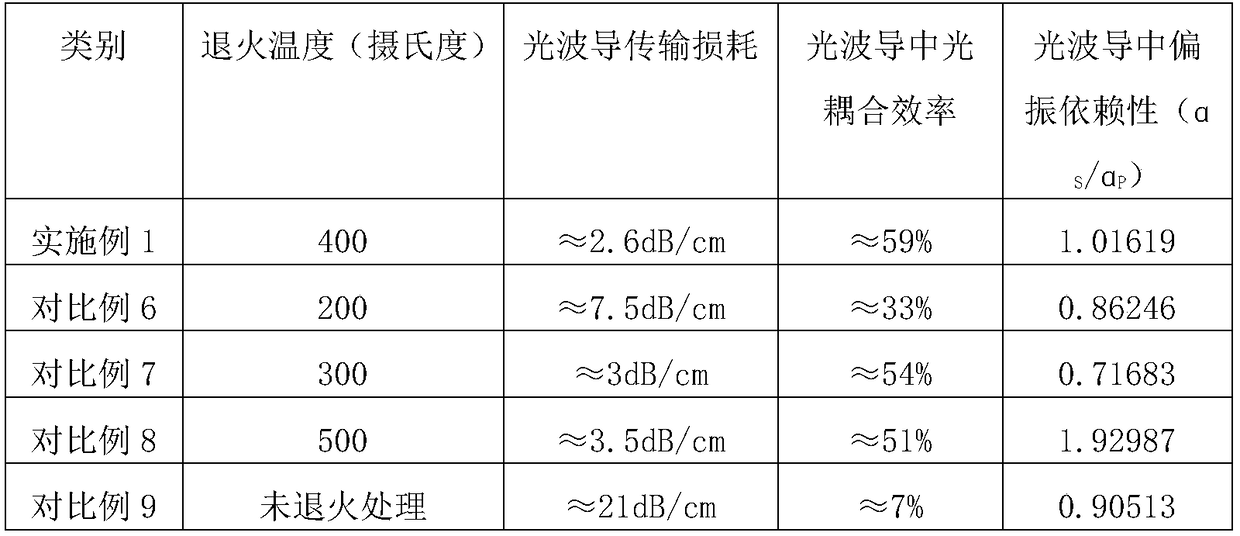

Embodiment 1

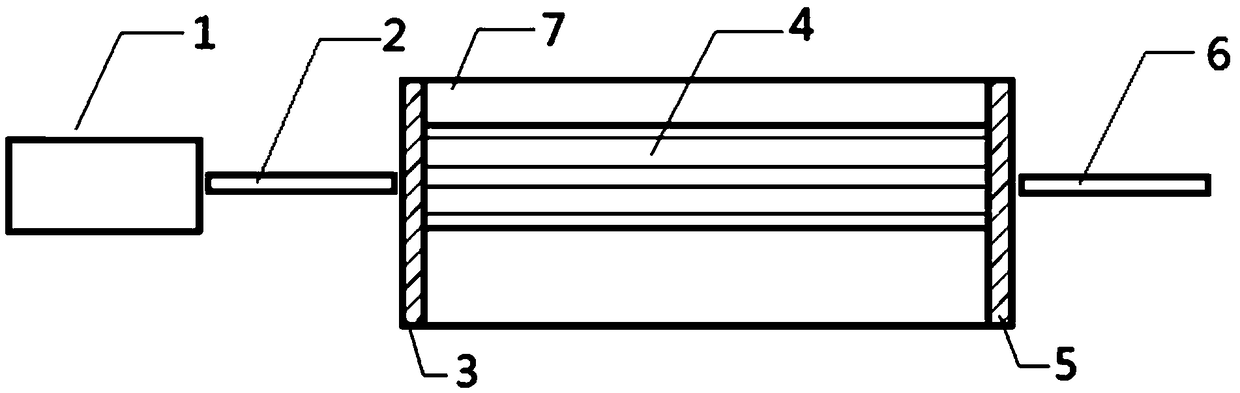

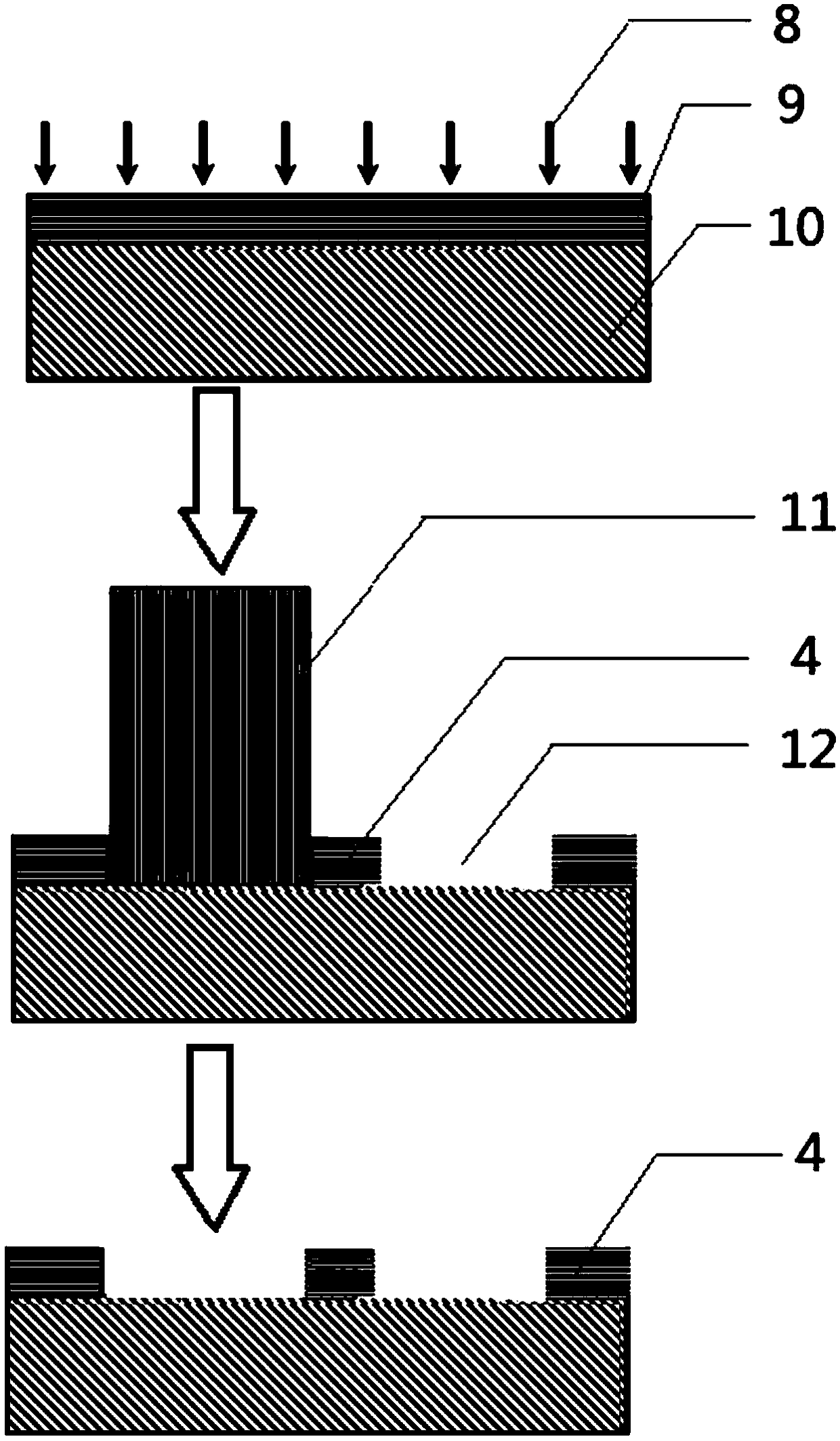

[0035] Such as figure 2 As shown, a method for preparing an optical waveguide based on oxygen ion implantation of terbium gallium garnet crystal includes the following steps:

[0036] (1) Optically polish the surface to be processed of the terbium gallium garnet crystal 10, and remove the surface impurities of the polished terbium gallium garnet crystal after optical polishing; c axis is vertical;

[0037] (2) Using an ion beam accelerator to emit an oxygen ion beam 8 to bombard the surface of the terbium gallium garnet crystal 10 to form a planar optical waveguide 9 with a thickness of 8 μm on the polished surface of the directly bombarded terbium gallium garnet crystal 10;

[0038] The oxygen ion beam 8 emitted by the ion beam accelerator has an energy of 15Mev and a dose of 1×10 15 ions / cm 2 ;

[0039] (3) A diamond cutting blade 11 is used in the planar optical waveguide 9 to cut two parallel grooves 12, the groove 12 has a depth of 8 μm and a width of 100 μm; the distance betwee...

Embodiment 2

[0043] A method for preparing an optical waveguide based on oxygen ion implantation of terbium gallium garnet crystal includes the following steps:

[0044] (1) Optically polish the surface to be processed of the terbium gallium garnet crystal 10, and remove the surface impurities of the polished terbium gallium garnet crystal after optical polishing; c axis is vertical;

[0045] (2) Using an ion beam accelerator to emit an oxygen ion beam 8 to bombard the surface of the terbium gallium garnet crystal 10, and form a flat optical waveguide 9 with a thickness of 9 μm on the polished surface of the terbium gallium garnet crystal 10 directly bombarded;

[0046] The oxygen ion beam 8 emitted by the ion beam accelerator has an energy of 16Mev and a dose of 5×10 15 ions / cm 2 ;

[0047] (3) A diamond cutting blade 11 is used to cut two parallel grooves 12 in the planar optical waveguide 9, the groove 12 has a depth of 9 μm and a width of 150 μm; the interval between the two grooves 12 is 25 μ...

Embodiment 3

[0051] A method for preparing an optical waveguide based on oxygen ion implantation of terbium gallium garnet crystal includes the following steps:

[0052] (1) Optically polish the surface to be processed of the terbium gallium garnet crystal 10, and remove the surface impurities of the polished terbium gallium garnet crystal after optical polishing; c axis is vertical;

[0053] (2) Using an ion beam accelerator to emit an oxygen ion beam 8 to bombard the surface of the terbium gallium garnet crystal 10 to form a planar optical waveguide 9 with a thickness of 10 μm on the polished surface of the terbium gallium garnet crystal 10 directly bombarded;

[0054] The oxygen ion beam 8 emitted by the ion beam accelerator has an energy of 17 Mev and a dose of 10×10 15 ions / cm 2 ;

[0055] (3) A diamond cutting blade 11 is used in the planar optical waveguide 9 to cut two parallel grooves 12, the groove 12 has a depth of 10 μm and a width of 200 μm; the distance between the two grooves 12 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com