Preparation method and application of ferroferric oxide nanoparticles

A technology of ferroferric oxide and nanoparticles, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of complex synthesis process, expensive raw materials, uneven sample shape, etc., and achieve rich sources and low prices , the effect of uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

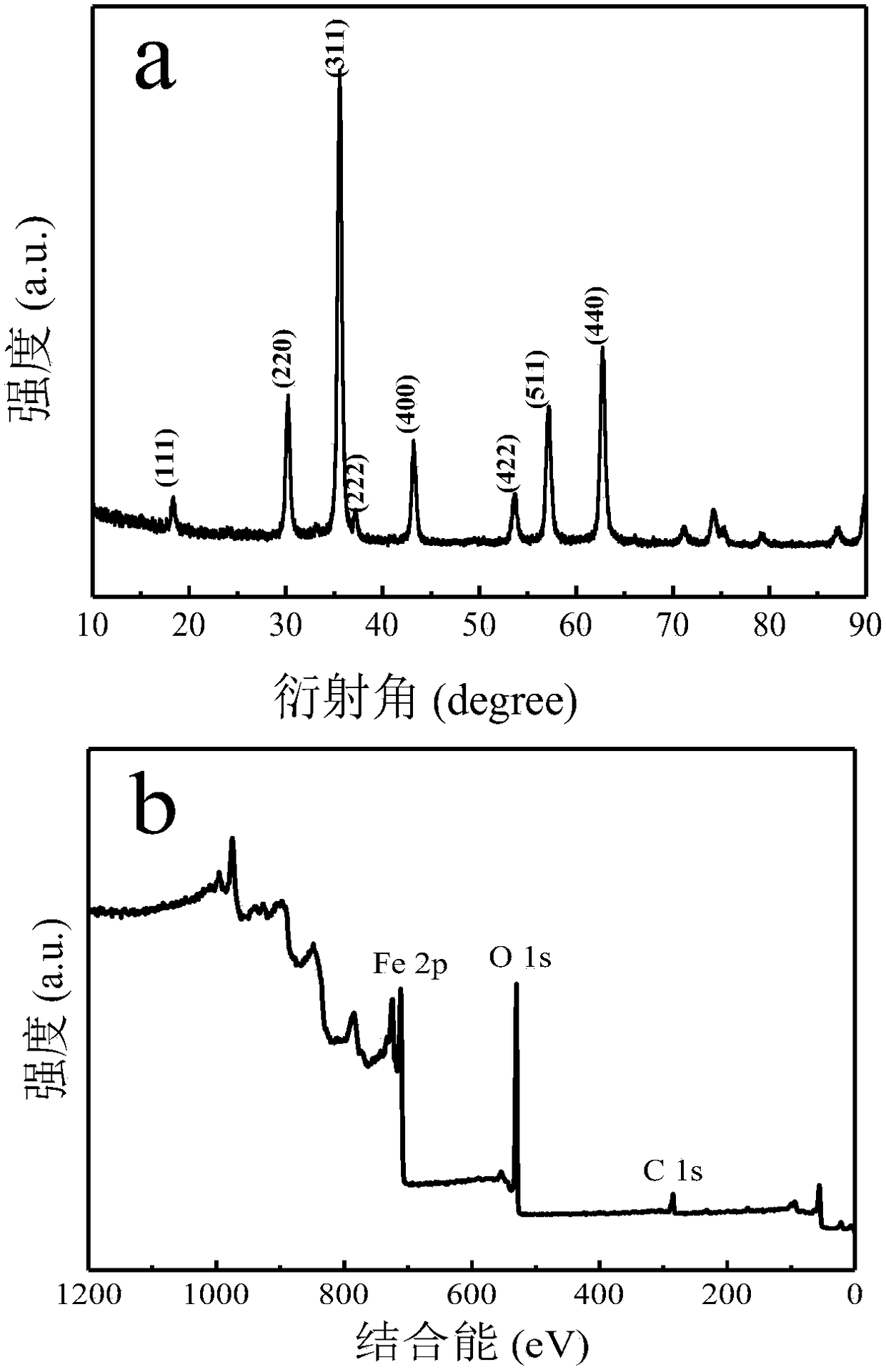

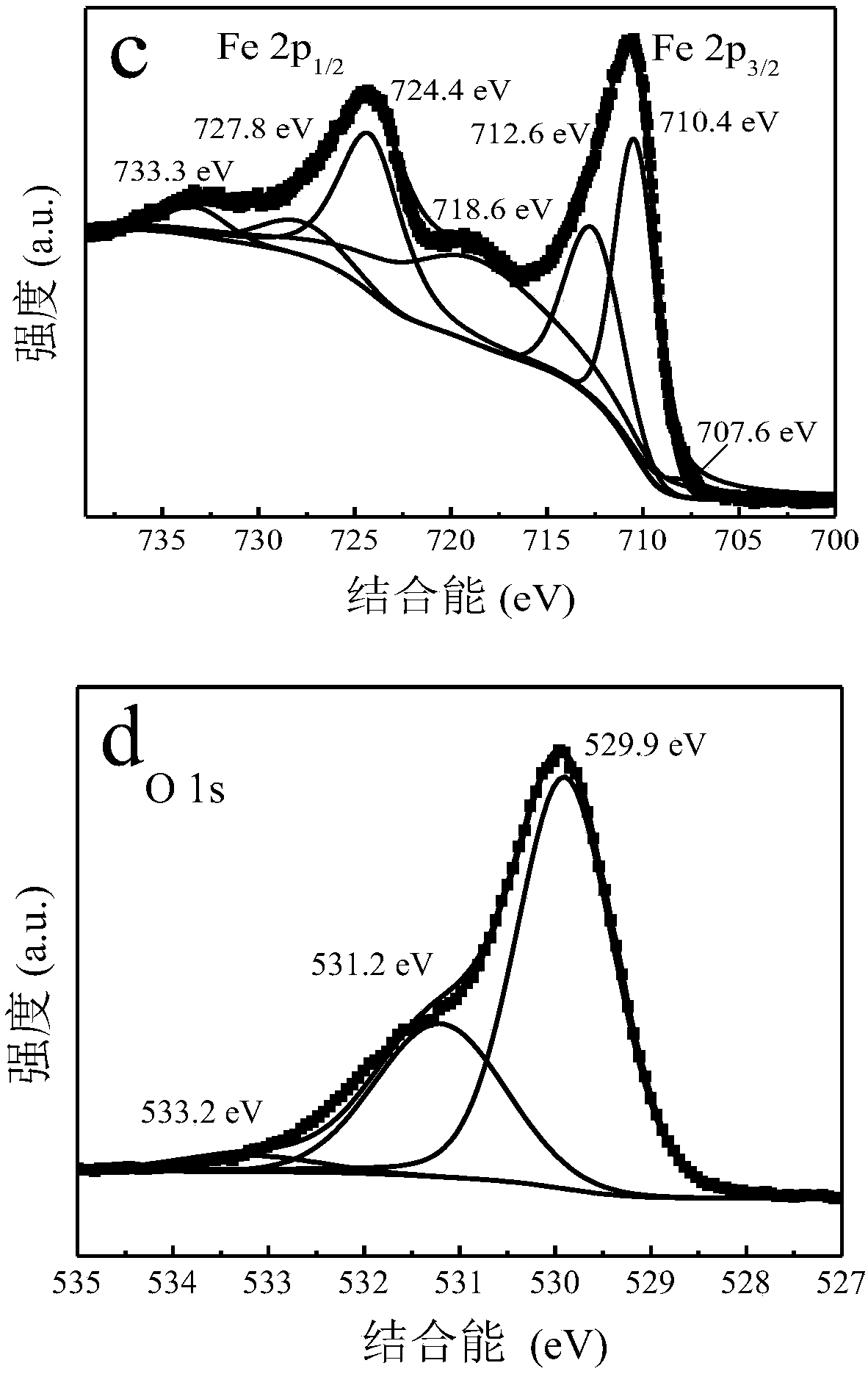

[0027] First, weigh 25mL of glycerol and 35mL of deionized water and mix them evenly; then add 6 mmol of ferric chloride hexahydrate and 6 mmol of urea and stir evenly to obtain a mixed solution; then transfer the mixed solution to a high-temperature and high-pressure reactor in 200°C for 10 h; finally cooled to room temperature naturally, washed three times with deionized water, washed once with absolute ethanol, magnetically separated, and vacuum-dried to obtain black magnetic Fe 3 o 4 nanoparticles.

Embodiment 2

[0029] First, weigh 25mL of glycerol and 15mL of deionized water and mix them evenly; then add 6mmol of ferric chloride hexahydrate and 6mmol of urea and stir evenly to obtain a mixed solution; then transfer the mixed solution to a high-temperature and high-pressure reactor , at 200°C, reacted for 10 h; finally cooled naturally to room temperature, washed three times with deionized water, washed once with absolute ethanol, magnetically separated, and dried in vacuum to obtain black magnetic Fe 3 o 4 nanoparticles.

Embodiment 3

[0031] First, weigh 35mL of glycerol and 25mL of deionized water and mix them evenly; then add 6mmol of ferric chloride hexahydrate and 6mmol of urea and stir evenly to obtain a mixed solution; then transfer the mixed solution to a high-temperature and high-pressure reactor , at 200°C, reacted for 10 h; finally cooled naturally to room temperature, washed three times with deionized water, washed once with absolute ethanol, magnetically separated, and dried in vacuum to obtain black magnetic Fe 3 o 4 nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com