Preparation method of electrode slice with high electrochemical performance

An electrochemical and electrode sheet technology, which is applied in the field of electrode sheet preparation, can solve the problems of low energy density of electrochemical capacitors, poor performance of porous carbon material products, and difficult control of pore structure, so as to achieve infiltration and rich pore structure. Sequence and pore structure rich and diverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the preparation method of banana peel-based activated carbon electrode sheet

[0036] (1) Wash the impurities on the surface of the banana peel, cut them into pieces with clean scissors, put them in a 101-2 oven produced by Shanghai Sanfa Instrument Co., Ltd., and dry them, and then pre-treat the banana peels: The dried banana peels are heated in a crucible and then placed in a muffle furnace, pre-oxidized at 250°C for 2-4 hours, and then cooled to room temperature to obtain pre-oxidized banana peels;

[0037] (2) Preparation of activated carbon: Preoxidized banana peel and ZnCl 2 Mix according to the mass ratio of 1:3, and add distilled water to make it fully mixed. After soaking for 24 hours, put the mixture in a blast drying oven to dry for 1.5 to 3 hours, and then put it in a tube resistance furnace. 2 In the presence of an inert atmosphere, the temperature was raised to 600, 700, 800, and 900°C at a rate of 5°C / min, and the temperature was gradually ...

Embodiment 2

[0042] Embodiment 2: performance test experiment

[0043] Each sample in embodiment 1 is carried out performance test from the following aspects, specifically as follows:

[0044] 1. Structural characterization

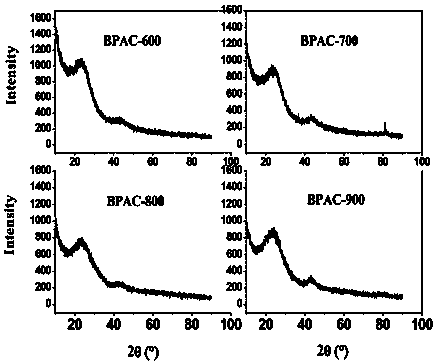

[0045] (1) XRD test

[0046] Select the D8 ADVANCE X-ray diffractometer produced by German Bruker Company to scan and carry out XRD test on the sample in Example 1, specifically: first grind the sample to be tested into powder, fill the sample tank and compact it, and set the working voltage of the instrument 35kV, scanning range 2θ=10~90°, the test results are as followsfigure 1 shown.

[0047] figure 1 The XRD curves of activated carbon obtained after activated carbonization at different temperatures are shown. It can be seen from the figure that the banana peel-based activated carbon has an obvious 002 peak at about 25°, and a low-intensity 100 peak near 42°, which shows that the obtained activated carbon is mainly amorphous. The activated carbon has a graphit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com