Enzymolysis feather powder being high in digestion coefficient and preparing method of enzymolysis feather powder

The technology of high digestibility enzyme and digestibility enzyme is applied in the field of high-efficiency enzymatic hydrolysis of feather meal and its preparation, which can solve the problems of large amount of water added, unsatisfactory product smell, difficult drying, etc. low water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

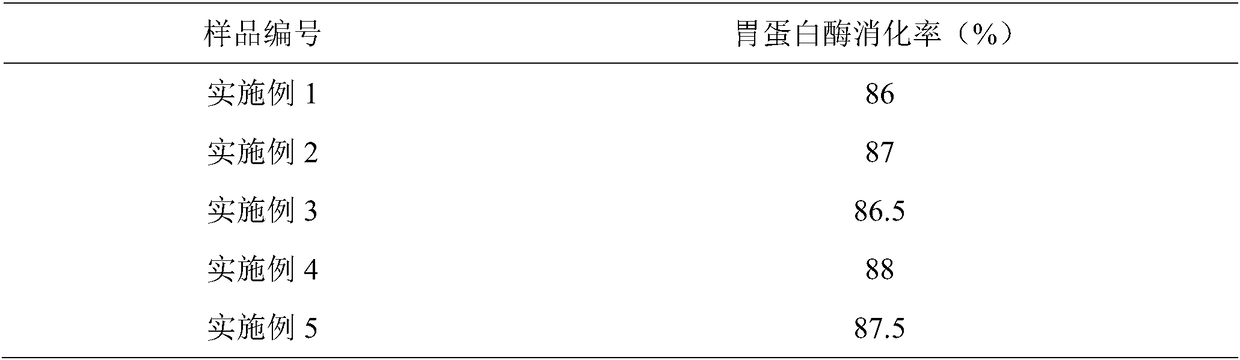

Examples

Embodiment 1

[0026] The preparation method of the high digestibility enzymolysis feather meal of the present embodiment comprises the following steps:

[0027] 1) Preparation of Bacillus licheniformis seed solution: Weigh 5.0g of peptone, 3.0g of beef extract, 5.0g of NaCl, add water to make up to 1000mL, adjust the pH to 7.0, sterilize at 121°C for 30min, cool to 30°C ℃, after inoculating the Bacillus licheniformis strain, culture it on a shaker at 120 rpm and 37° C. for 18 hours to obtain the Bacillus licheniformis seed liquid.

[0028] 2) Preparation of secondary strains of Bacillus licheniformis: Weigh 7kg of soybean meal powder, 3kg of corn flour, add 4kg of water and mix, then sterilize the mixture of soybean meal, corn flour and water at 121°C for 1 hour, and cool to 37°C , inoculate 1000 mL of the Bacillus licheniformis seed liquid in step 1), spread it to a thickness of 5 cm, and incubate at 37° C. for 24 hours to obtain the secondary strain of Bacillus licheniformis.

[0029] 3)...

Embodiment 2

[0037] The preparation method of the high digestibility enzymolysis feather meal of the present embodiment comprises the following steps:

[0038] 1) Preparation of plant lactic acid bacteria seed liquid: weigh 10.0g of casein peptone, 10.0g of beef extract, 5.0g of yeast powder, 5.0g of glucose, 5.0g of sodium acetate, 2.0g of diammonium citrate, 1.0g of Tween 80, 2.0 g K 2 HPO 4 , 0.2g MgSO 4 .7H 2 O, 0.05g MnSO 4 .H 2 O, 20.0 g CaCO 3 , add water to the volume to 1000mL, adjust the pH to 6.8, sterilize at 121°C for 20 minutes, cool to 30°C, inoculate Lactobacillus plantarum strains, and cultivate on a shaker at 130rpm and 37°C for 18h to obtain plant Lactobacillus seed liquid.

[0039] 2) Preparation of secondary strains of plant lactic acid bacteria: Weigh 6kg of soybean meal powder, 4kg of corn flour, add 4kg of water and mix well, then sterilize the mixture of soybean meal powder, corn flour and water at 121°C for 0.5h, and cool to 30°C , inoculate 1000 mL of the ...

Embodiment 3

[0046] The preparation method of the high digestibility enzymolysis feather powder of the present embodiment of the present embodiment comprises the following steps:

[0047] 1) Preparation of Bacillus licheniformis seed liquid: Weigh 5.0g of peptone, 3.0g of beef extract, and 5.0g of NaCl, add water to make the volume 1000mL, adjust the pH to 7.0, sterilize at 121°C for 20min, and cool to 25 ℃, after inoculating the Bacillus licheniformis strain, culture it on a shaker at 160 rpm and 37° C. for 20 hours to obtain the Bacillus licheniformis seed solution.

[0048] 2) Preparation of secondary strains of Bacillus licheniformis: Weigh 7kg of soybean meal powder, 3kg of corn flour, add 4kg of water and mix well, then sterilize the mixture of soybean meal, corn flour and water at 125°C for 0.5h, and cool to 40 ℃, inoculate 1000 mL of the Bacillus licheniformis seed solution in step 1), spread it to a thickness of 10 cm, and culture it at 40° C. for 18 hours to obtain the secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com