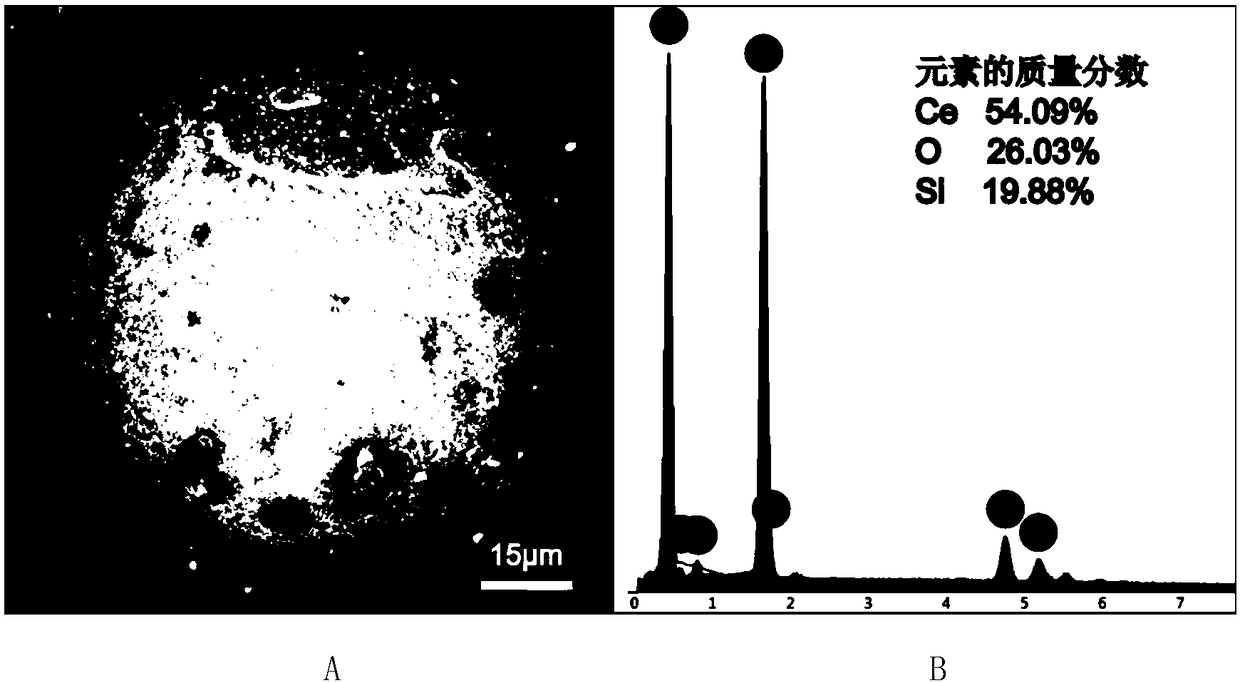

Preparation and application of cerium oxide modified porous silicon-based microsphere adsorbent

A technology based on porous silicon and cerium oxide, which is applied in the direction of adsorption of water/sewage treatment, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as difficult application of column separation technology and limit industrial application, and achieve product Good sphericity, cost-saving experiment, and wide-ranging sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of tetravalent cerium salt solution: 9g CeCl 3 ·7H 2 O was dissolved in 90g of distilled water, and then 1.8g of 30% H 2 o 2 Add it dropwise to the above solution while stirring, and then let it stand for 1 hour to make it oxidize more thoroughly;

[0035] (2) Carrying of tetravalent cerium salt: the tetravalent cerium salt aqueous solution of step (1) and 25g porous silica microspheres are transferred in the eggplant-shaped flask together, and the rotation speed of the control rotary evaporator is 30rpm, and rotary evaporation The temperature is 45 degrees Celsius, the vacuum degree is maintained at 5KPa, and the rotary evaporation time is 3 hours;

[0036] (3) Aging: the porous silica microspheres loaded with tetravalent cerium salt in step (2) are poured into 20 milliliters of ammonia water with a mass fraction of 10%, and the pH value of the control solution is 8, and at 60 Heating for half an hour in a water bath at 100°C, then standing and agin...

Embodiment 2

[0043] (1) Preparation of tetravalent cerium salt solution: 7.5gCeCl 3 ·7H 2 O was dissolved in 120g of distilled water, and then 3g of 30% H 2 o 2 Add it dropwise to the above solution while stirring, and then let it stand for 2 hours to make it oxidize more thoroughly;

[0044] (2) Loading of tetravalent cerium salt: the tetravalent cerium salt aqueous solution of step (1) and 15g porous silica microspheres are transferred together in the eggplant-shaped flask, and the rotation speed of the control rotary evaporator is 100rpm, and the rotary evaporation The temperature is 60 degrees Celsius, the vacuum degree is maintained at 60KPa, and the rotary evaporation time is 2 hours;

[0045] (3) Aging: the porous silica microspheres loaded with tetravalent cerium salt in step (2) are poured into 30 milliliters of ammonia water with a mass fraction of 15%, the pH value of the control solution is 11, and at 90 Heating for half an hour in a water bath at 100°C, then standing and a...

Embodiment 3

[0052] (1) Preparation of tetravalent cerium salt solution: 12gCe 2 (SO 4 ) 3 ·8H 2 O was dissolved in 150g of distilled water, and then 5g of 30% H 2 o 2 Add it dropwise to the above solution while stirring, then let it stand for 8 hours to make it oxidize more thoroughly;

[0053] (2) Carrying of tetravalent cerium salt: the tetravalent cerium salt aqueous solution of step (1) and 25g porous silica microspheres are transferred together in the eggplant-shaped flask, and the rotational speed of the control rotary evaporator is 150rpm, and rotary evaporation The temperature is 80 degrees Celsius, the vacuum degree is maintained at 50KPa, and the rotary evaporation time is 4 hours;

[0054] (3) Aging: the porous silica microspheres loaded with tetravalent cerium salt in step (2) are poured into 20 milliliters of ammonia water with a mass fraction of 20%, and the pH value of the control solution is 9, and at 80 Heating for half an hour in a water bath at 100°C, then standin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com