Biological medical fertilizer and preparation method thereof

A biomedical fertilizer and mixture technology, applied in the direction of nitrogen fertilizer, potassium fertilizer, phosphate fertilizer, etc., can solve the problems of food pollution, ecological damage, resource waste, etc., and achieve the effect of high utilization rate, high absorption and utilization rate, and reasonable nutrient distribution ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

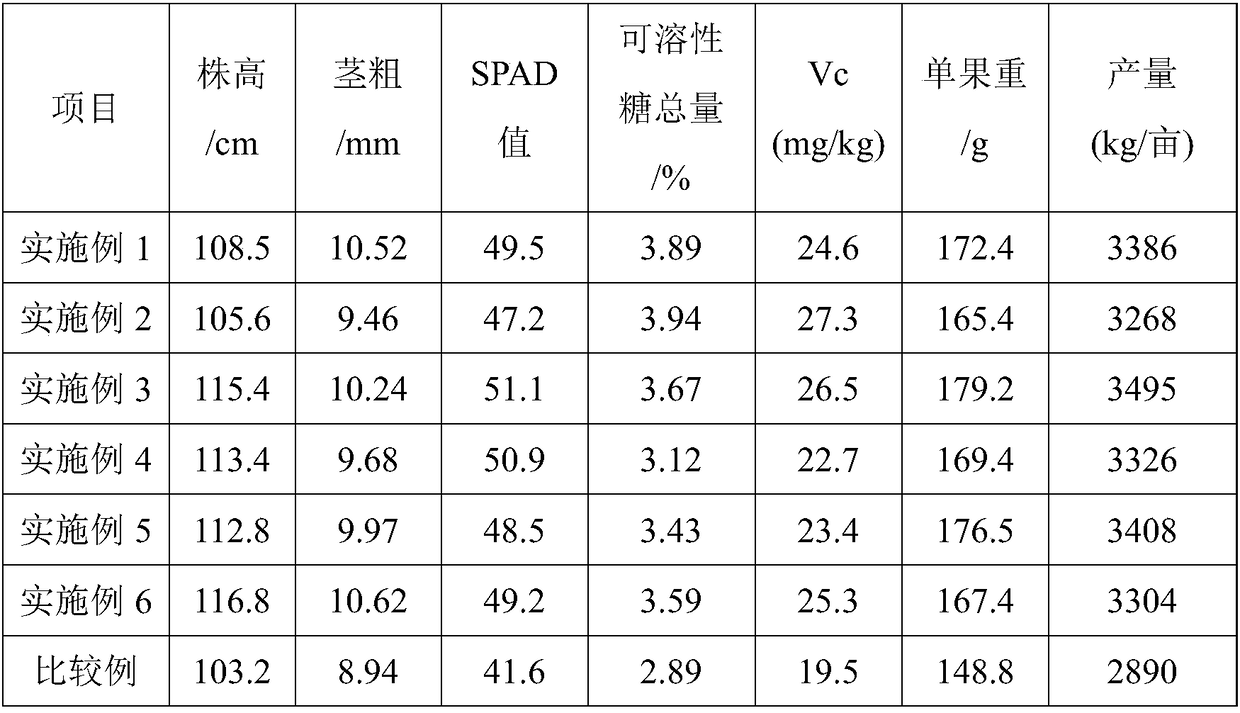

Examples

Embodiment 1

[0021] Add 165.5kg of water to the reaction kettle, start heating to 45°C, adjust to heat preservation state, start stirring, add 1.5kg of diethylenetriaminepentacarboxylic acid, stir for 10min until completely dissolved, add 25kg of urea ammonium nitrate solution, 200kg of polyphosphoric acid Ammonium solution, 90kg potassium pyrophosphate and stir for 60min until completely dissolved, add 3.5kg boric acid, 2.5kg EDTA-Fe-13, 2.5kgEDTA-Mn-13, 1.0kg EDTA-Cu-15, 3.0kg EDTA-Zn-15 and stir for 20min Until it is completely dissolved, add 2.5kg of diethyl diethyl ethyl hexanoate and 1.0kg of brassinolide and stir for 10 minutes until it is completely dissolved, then add 1kg of carboxylic acid type anionic silicone surfactant and stir for 10 minutes until it is completely dissolved, and a stable and uniform liquid is obtained.

Embodiment 2

[0023] Add 197.45kg of water to the reactor, turn on the heating to 45°C, adjust to the heat preservation state, start stirring, add 0.5kg of ethylenediaminetetraacetic acid, stir for 5min until completely dissolved, add 40kg of urea, 155kg of potassium acetate, 90kg of pyrophosphoric acid Potassium was stirred for 50 minutes until completely dissolved, then added 7.5kg disodium octaborate tetrahydrate, 2.5kg EDTA-Fe-13, 4.0kg EDTA-Zn-15, 0.05kg ammonium molybdate and stirred for 15 minutes until completely dissolved, then added 1kg diethyl diethyl ethyl hexanoate , 1kg brassinolide, 0.5kg forchlorfenuron, stirred for 10 minutes until completely dissolved, and finally added 0.6kg carboxylic acid type anionic silicone surfactant and 0.4kg lecithin, stirred for 10 minutes until completely dissolved, and a stable and uniform liquid was obtained.

Embodiment 3

[0025] Add 100.19kg of water to the reactor, turn on the heating to 40°C, adjust to the heat preservation state, start stirring, add 1.5kg of diethylenetriaminepentacarboxylic acid, stir for 10min until completely dissolved, add 90kg of urea, 165kg of ammonium polyphosphate solution , 125kg of potassium acetate and stirred for 60min until completely dissolved, adding 5kg of disodium octaborate tetrahydrate, 3.25kg of EDTA-Fe-13, 2.5kg of EDTA-Mn-13, 1.5kg of EDTA-Cu-15, 2.5kg of EDTA-Zn-15, Stir 0.06kg ammonium molybdate for 20 minutes until completely dissolved, add 2.0kg brassinolide, 0.5kg polyglutamic acid and stir for 10 minutes until completely dissolved, then add 0.3kg carboxylic acid anionic silicone surfactant and 0.7kg dodecyl Sodium alkylbenzene sulfonate was stirred for 10 minutes until it was completely dissolved, and a stable and uniform liquid was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com