A kind of polyvinylidene fluoride resin and its preparation method and application

A technology of polyvinylidene fluoride resin and vinylidene fluoride, which is applied in the field of polyvinylidene fluoride resin and its preparation, can solve the problems of poor processing performance and insufficient strength, and achieves improved processing performance, improved impact resistance, good phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

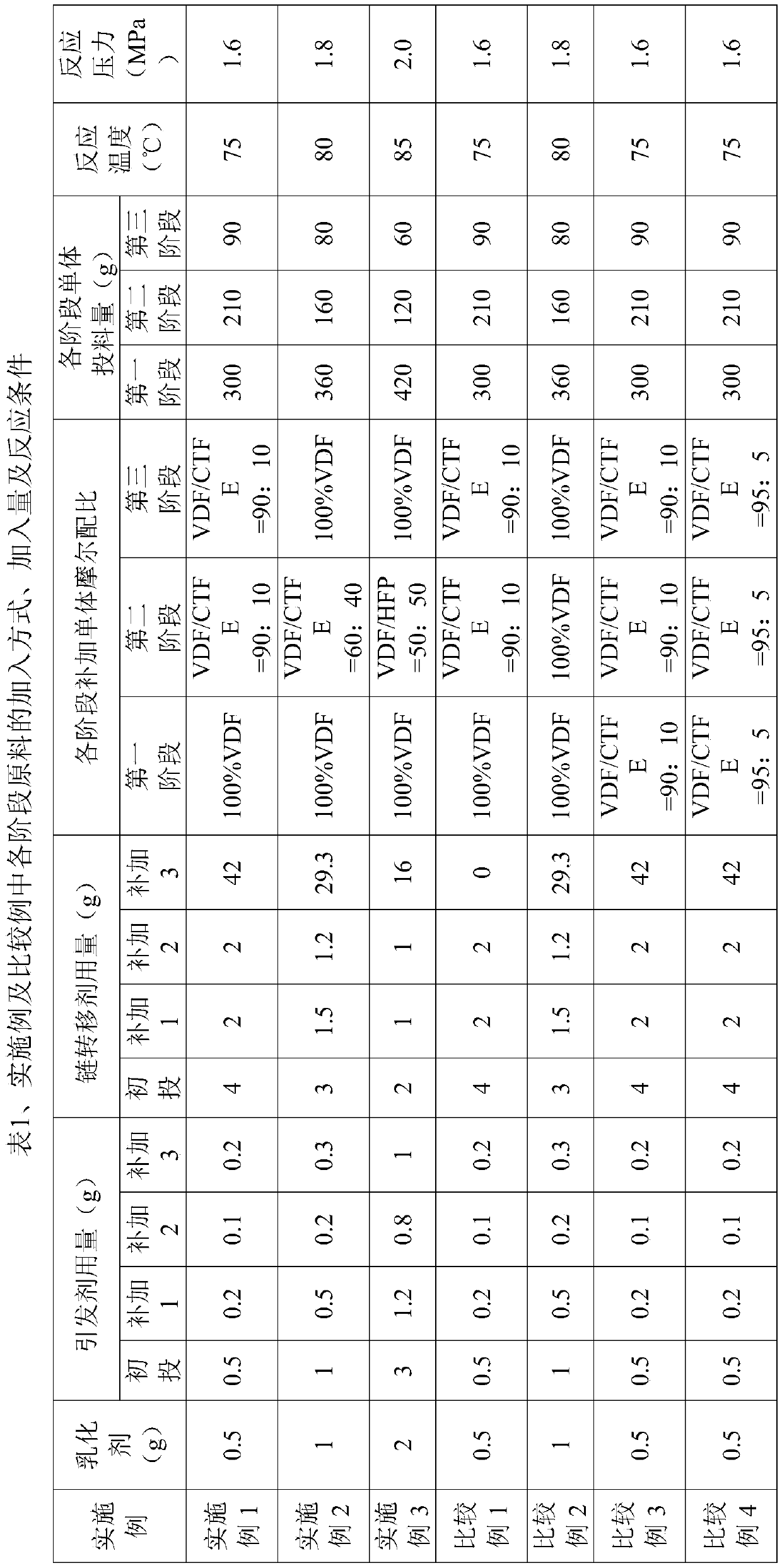

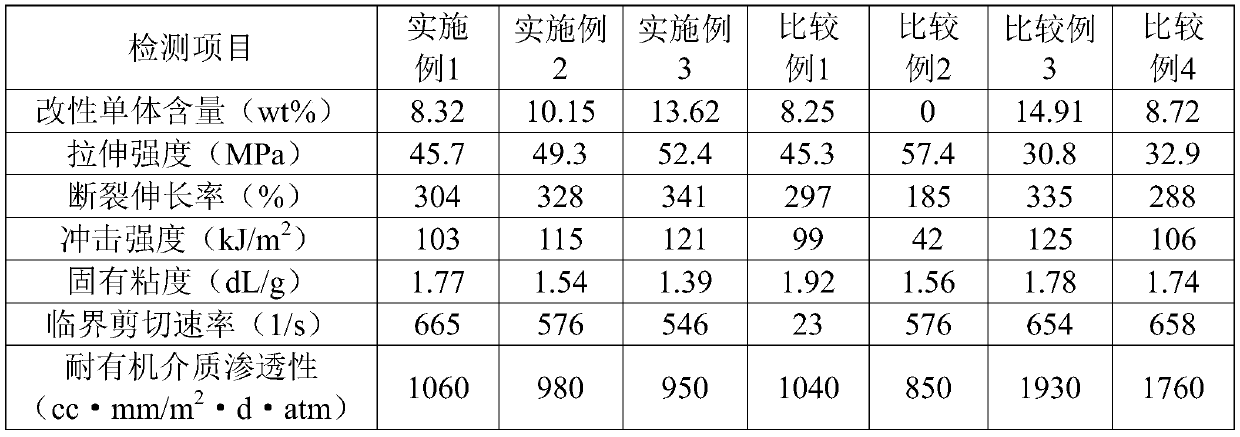

[0065] Embodiment 1, preparation polyvinylidene fluoride resin

[0066] Add 2500g of deionized water and ammonium perfluorooctanoate emulsifier into a 5L vertical kettle (300rpm), then raise the temperature of the polymerization kettle and add VDF monomer. After the temperature of the polymerization kettle reaches 75°C and the pressure of the kettle reaches 1.6MPa, pass Add the initiator diisopropyl peroxydicarbonate and the chain transfer agent acetone to the auxiliary pump to start the reaction. During the reaction, the addition methods of the monomer, initiator and chain transfer agent are shown in Table 1. Stable to the completion of the reaction, wherein, the first stage stops the reaction when the consumption of vinylidene fluoride monomer is 50% (300g VDF) of the total monomer total weight of the three stages; the second stage is when the consumption of the mixed monomer is three Stop reaction when 35% (210g mixed monomer) of all monomer gross weights of the stage; Stop...

Embodiment 2

[0069] Embodiment 2, preparation polyvinylidene fluoride resin

[0070] Add 2800g of deionized water and potassium perfluorooctanoate emulsifier into a 5L vertical kettle (350rpm), then raise the temperature of the polymerization kettle and add VDF monomer. After the temperature of the polymerization kettle reaches 80°C and the pressure of the kettle reaches 1.8MPa, pass The auxiliary pump adds the initiator diethyl peroxydicarbonate and the chain transfer agent ethyl acetate to start the reaction. During the reaction, the addition methods of the monomer, initiator and chain transfer agent are shown in Table 1. Keep the reactor still warm. The pressure is stabilized to the completion of the reaction, wherein, the first stage stops the reaction when the consumption of vinylidene fluoride monomer is 60% (360g VDF) of the total monomer total weight of the three stages; the second stage is when the consumption of the mixed monomer is three Stop reaction when 27% (160g mixed monome...

Embodiment 3

[0073] Embodiment 3, preparation polyvinylidene fluoride resin

[0074] Add 3000g of deionized water and sodium perfluorooctanoate emulsifier into a 5L vertical kettle (rotating speed: 400rpm), then raise the temperature of the polymerization kettle and add VDF monomer. After the temperature of the polymerization kettle reaches 85°C and the pressure of the kettle reaches 2.0MPa, pass Add the initiator tert-butyl peroxypivalate and the chain transfer agent diethyl carbonate to the auxiliary pump to start the reaction. The addition methods of the monomer, initiator and chain transfer agent during the reaction are shown in Table 1. Warm autoclave pressure is stabilized to the completion of reaction, wherein, the first stage stops reaction when the vinylidene fluoride monomer consumption is 70% (420g VDF) of all monomer gross weights of three stages; The second stage is when the mixed monomer consumption Stop reaction when being 20% (120g mixed monomer) of all monomer gross weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com