A kind of preparation method of perovskite film layer and perovskite light-emitting diode device

A light-emitting diode and perovskite technology, applied in the field of electroluminescent diode devices, can solve the problems of low perovskite film coverage, affecting device performance, and low raw material utilization, and achieve easy operation, improved luminous intensity, and coverage large effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

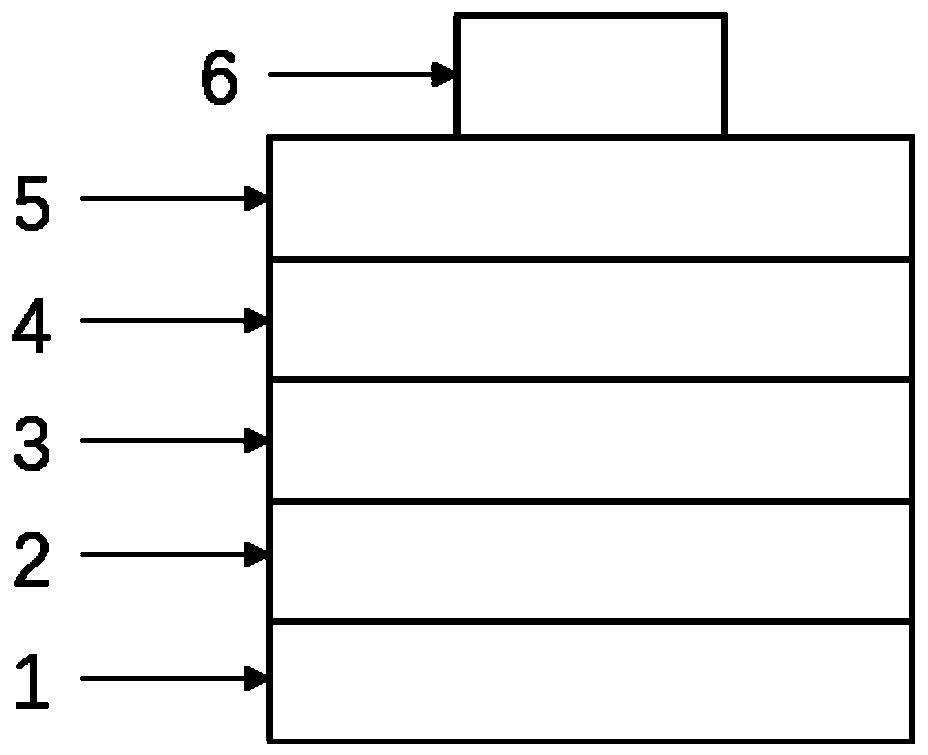

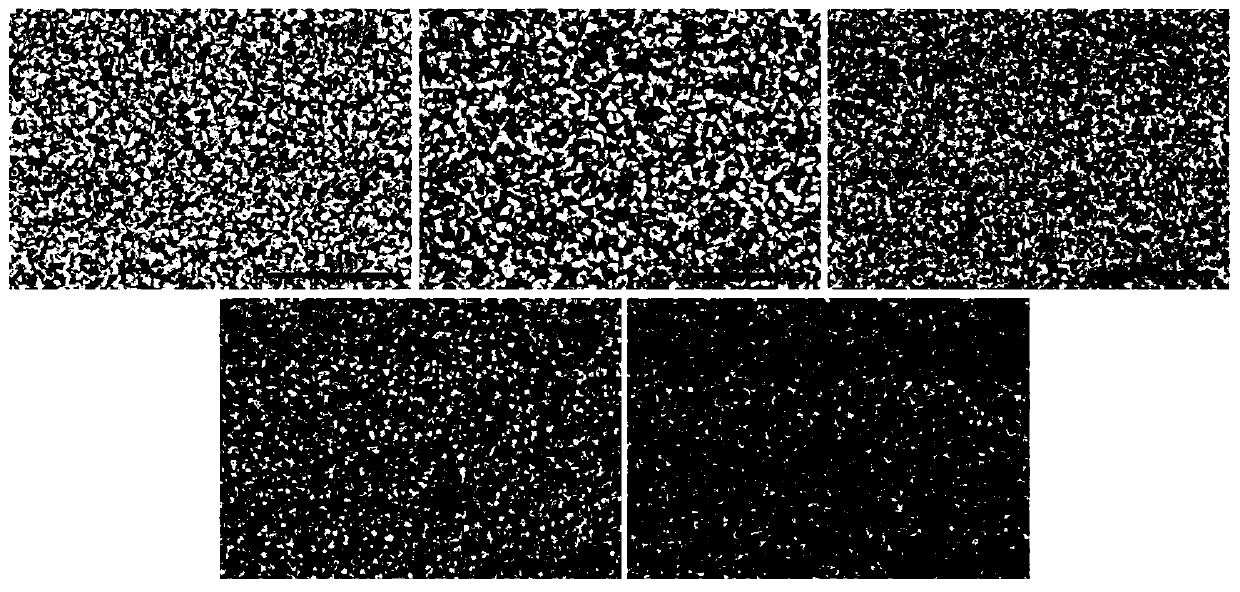

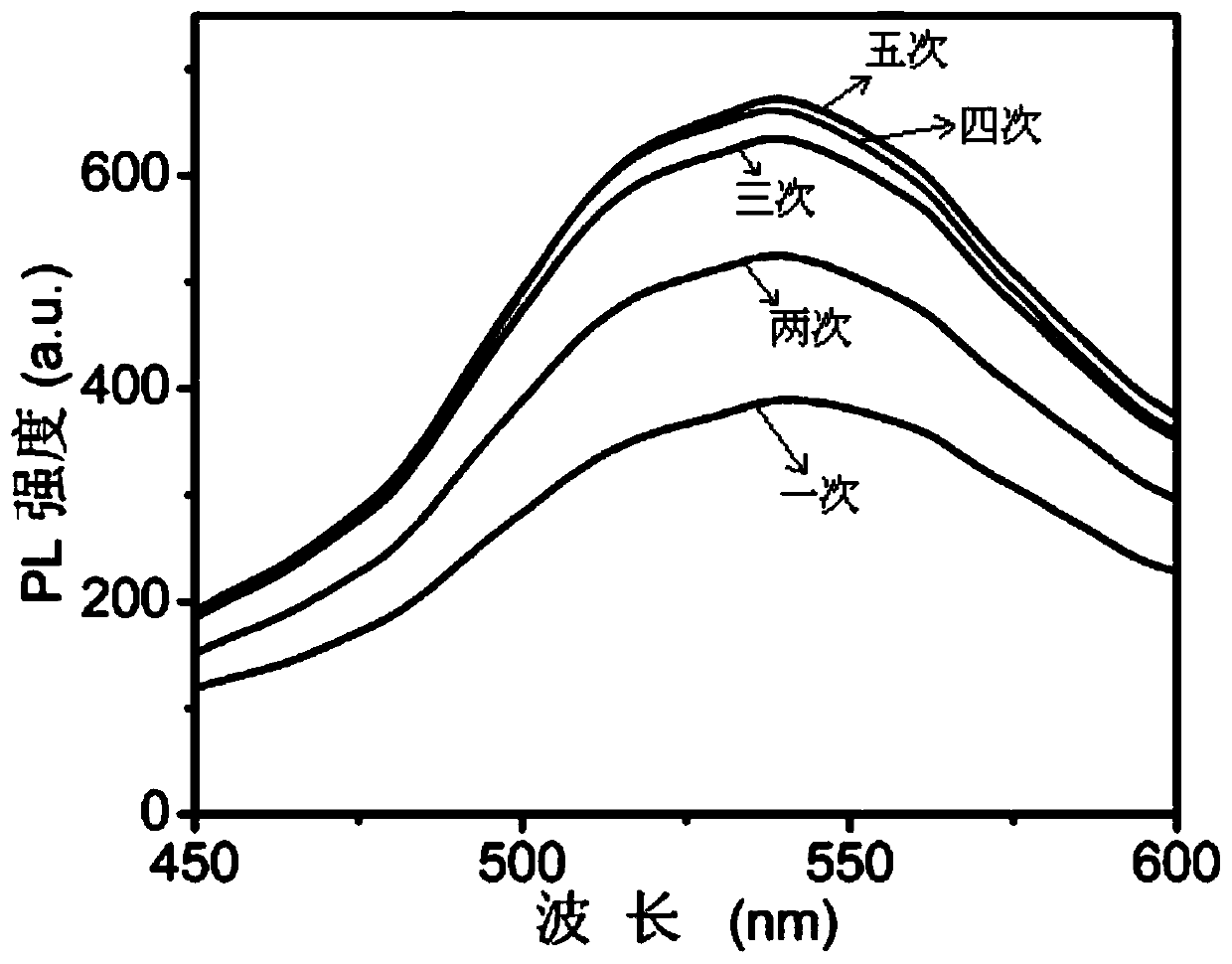

[0029] A perovskite light-emitting diode device is prepared with a structure such as figure 1 As shown, wherein the light-emitting layer is a perovskite film layer prepared by multiple spin coating methods; the preparation method of the perovskite light-emitting diode device includes the following steps:

[0030] 1) The transparent conductive glass substrate 1 is processed, wherein the transparent conductive glass substrate 1 is a smoked tin oxide (ITO) substrate.

[0031] First, rinse the transparent ITO conductive glass substrate in deionized water, then scrub it with acetone, ethanol, and deionized water, then use an ultrasonic instrument to ultrasonicate it in acetone, ethanol, and deionized water for 10 minutes, and finally bake it in a clean environment until Removes moisture completely.

[0032] 2) Preparation of the hole transport layer 2 .

[0033] Put the cleaned and dried transparent ITO conductive glass substrate in a UV ozone cleaner for 10 minutes, then spin-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com