A kind of negative electrode aqueous lithium supplement additive and preparation method thereof

An additive, water-based technology, applied in battery electrodes, secondary battery repair/maintenance, structural parts, etc., can solve problems such as cost increase, efficiency reduction, and inability to use negative electrode lithium supplementation additives, achieving easy operation, improving first efficiency, Improve the effect of gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

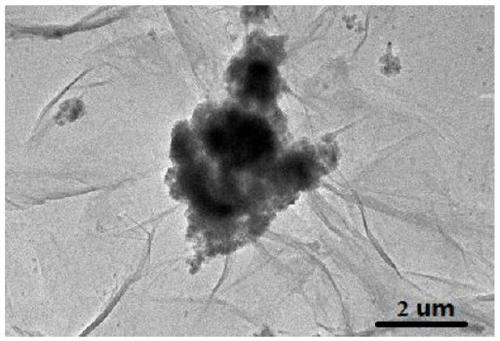

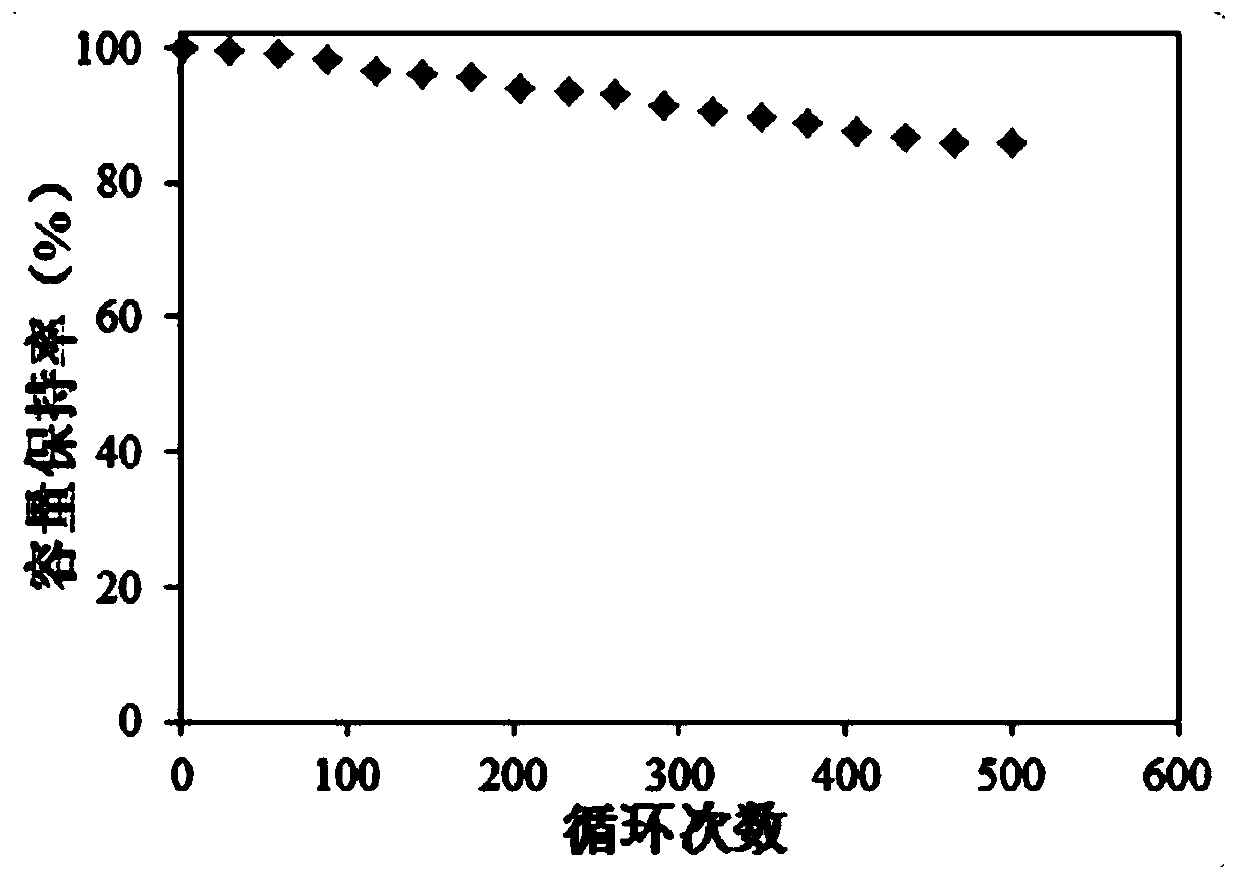

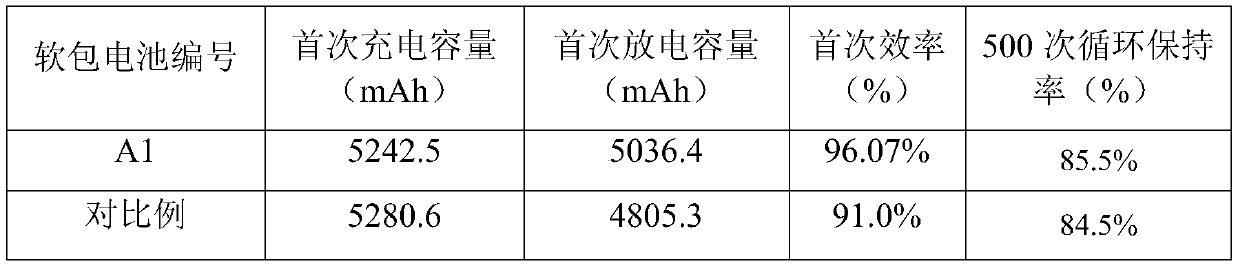

[0032] Mix 1.0g of polytetrafluoroethylene with 100.0g of deionized water, and stir thoroughly for 30 minutes to form a stable glue. Then, add 5.0 g of silicon powder to the glue, stir it ultrasonically to completely immerse it, let it stand for 2 minutes, filter it, and dry it in a vacuum oven at 45°C to obtain product A. In an environment with a dew point of -40°C, the above-mentioned product A was mixed with 25.0 g of pure lithium liquid under an argon atmosphere, and kept reacting at 185°C for 20 minutes, then cooled and left for 30 minutes to form product B. Then add product B and 0.1g graphite oxide to the mixed solution of ethanol and deionized water (V:V=5:5), and transfer to the microwave reactor, adjust the microwave power to 360W, and heat the mixed solution to the reflux state , slowly add 0.3g ascorbic acid to it, keep the reaction for 15min after the dropwise addition, cool at room temperature, centrifuge, collect the precipitate, wash, and vacuum-dry to obtain t...

Embodiment 2

[0035] Mix 2.0g polyvinylidene fluoride with 100.0g deionized water, stir well for 30min to form a stable glue. Then add 10.0g of silicon powder to the glue, stir it ultrasonically to completely immerse it, let it stand for 8 minutes, filter it, and dry it in a vacuum oven at 45°C to obtain product A. In an environment with a dew point of -45°C, the above-mentioned product A was mixed with 48.0 g of pure lithium liquid under an argon atmosphere, and kept reacting at 190°C for 25 minutes, then cooled and left for 30 minutes to form product B. Then add product B and 0.2g graphite oxide to the mixed solution of ethanol and deionized water (V:V=6:4), and transfer to the microwave reactor, adjust the microwave power to 400W, and heat the mixed solution to the reflux state , slowly add 0.7g of hydrazine hydrate to it, keep the reaction for 20min after the dropwise addition, cool at room temperature, centrifuge, collect the precipitate, wash, and vacuum dry to obtain the product.

Embodiment 3

[0037]Mix 3.0g of FEP with 100.0g of deionized water, stir well for 25min to form a stable glue. Then add 5.0g of silicon powder to the glue, stir it ultrasonically to completely immerse it, let it stand for 5 minutes, filter it, and dry it in a vacuum oven at 45°C to obtain product A. In an environment with a dew point of -40°C, the above product A was mixed with 30.0 g of pure lithium liquid under an argon atmosphere, and kept reacting at 180°C for 20 minutes, then cooled and left for 30 minutes to form product B. Then add product B and 0.1g graphite oxide to the mixed solution of ethanol and deionized water (V:V=8:2), and transfer to the microwave reactor, adjust the microwave power to 300W, and heat the mixed solution to reflux , slowly add 0.2g of ammonia water and 0.4g of hydrazine hydrate to it, keep the reaction for 15min after the dropwise addition, cool at room temperature, centrifuge, collect the precipitate, wash, and vacuum-dry to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com