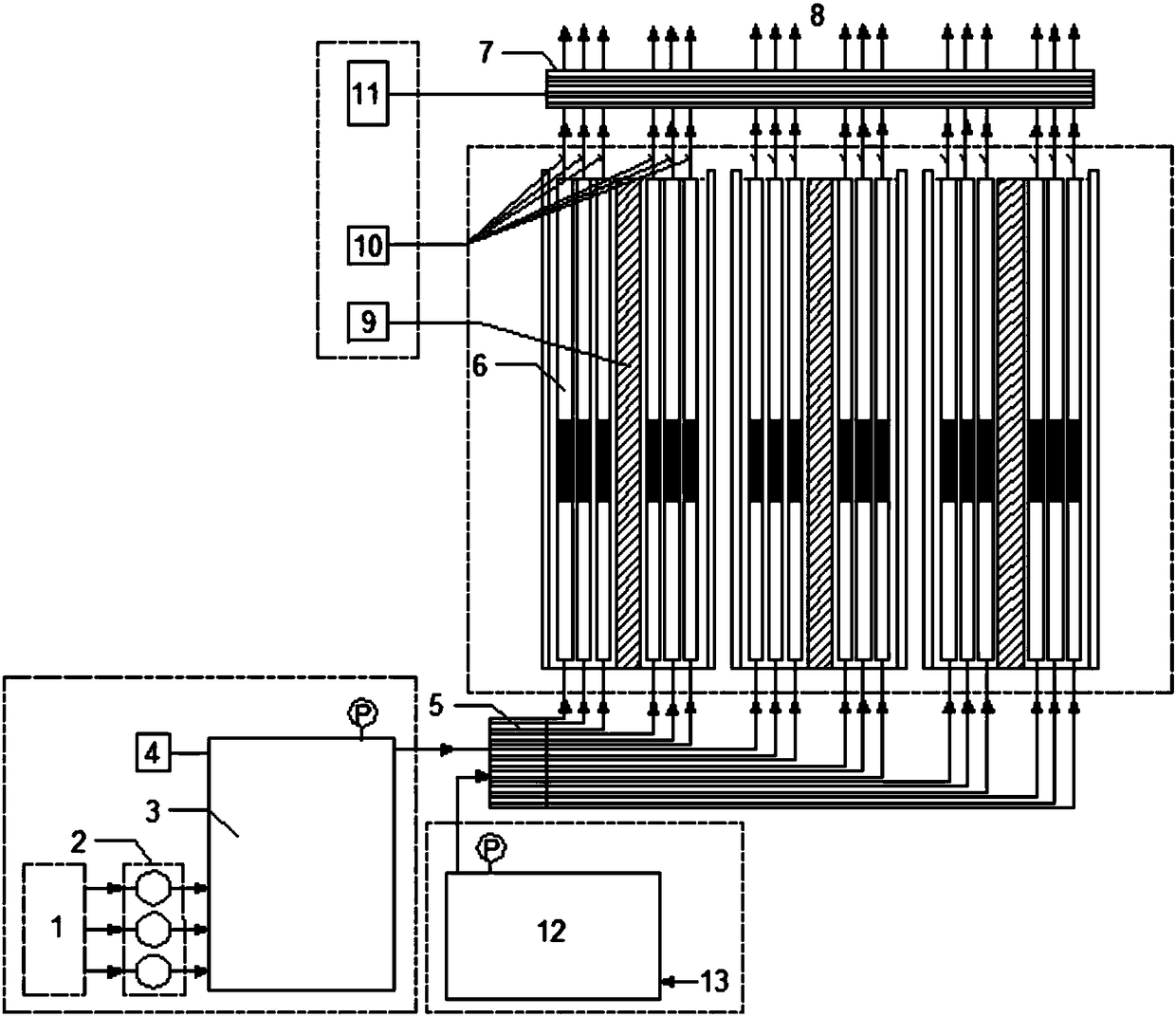

Multifunctional experimental device for purifying gaseous pollutants

A technology for experimental devices and pollutants, applied in measurement devices, chemical instruments and methods, instruments, etc., can solve problems such as high consumption and low efficiency, and achieve the effects of reducing device investment, flexible expansion, and reducing space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

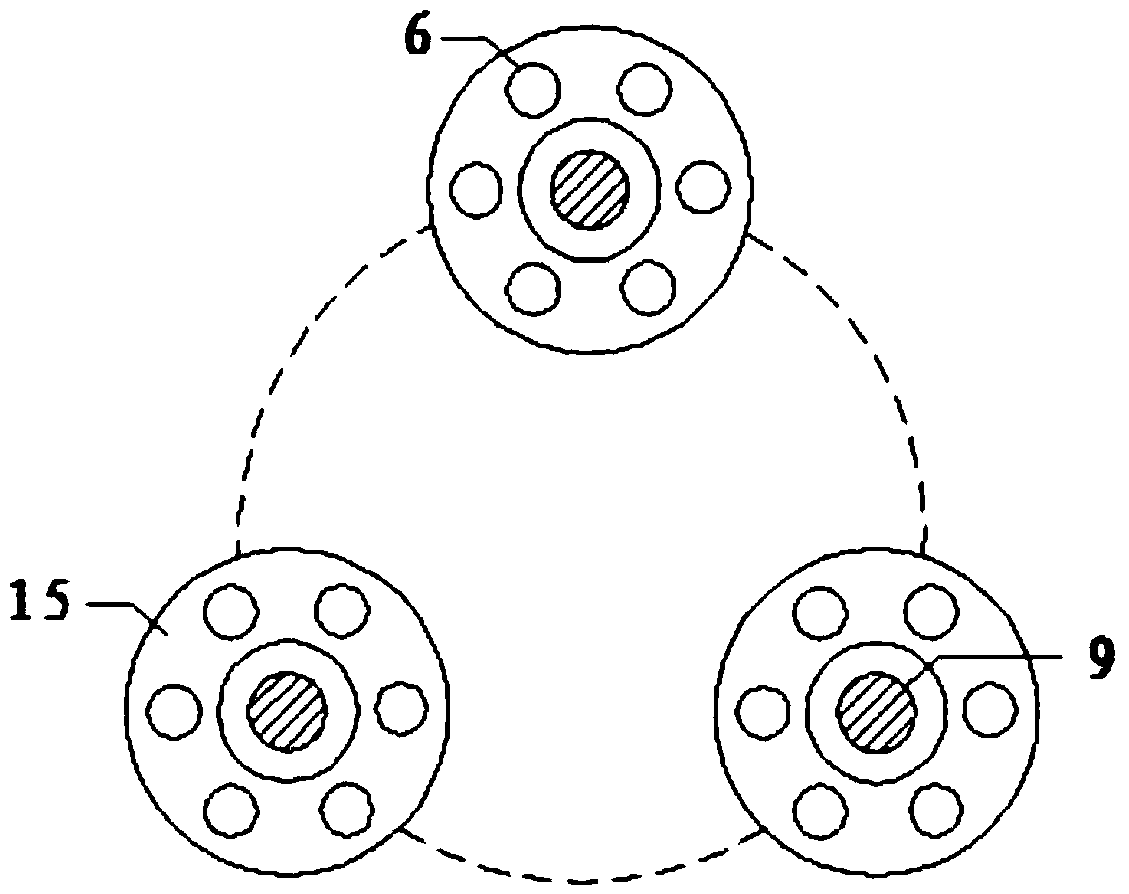

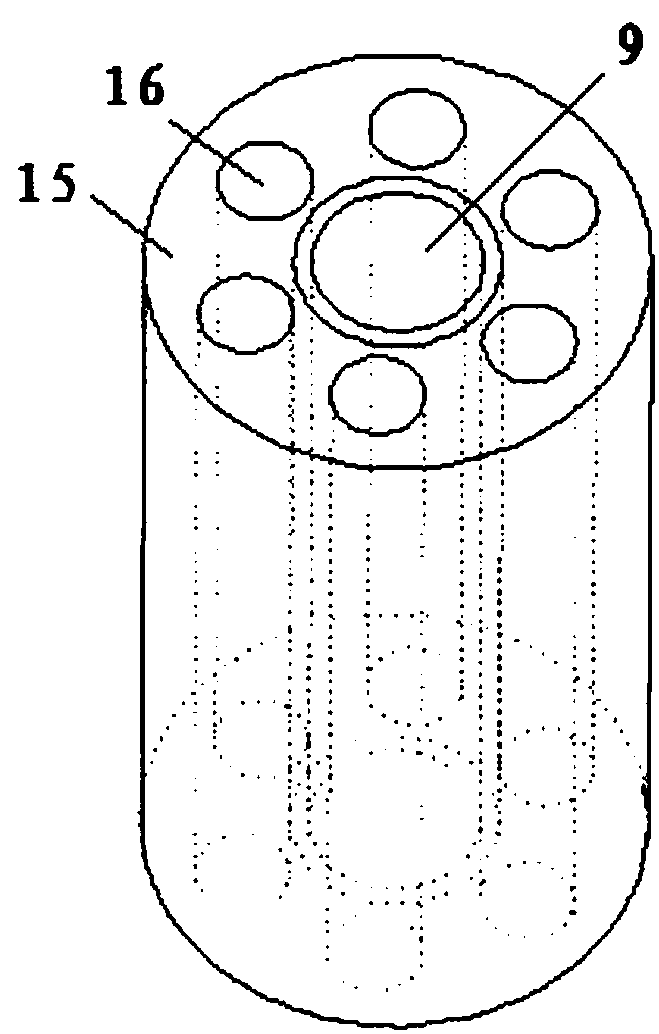

Method used

Image

Examples

Embodiment 1

[0028] Example 1: SO 2 Exhaust gas adsorption teaching experiment.

[0029] A university carried out experimental teaching of waste gas adsorption and purification. The content of the experiment was to measure the adsorption of SO by activated carbon in a fixed bed. 2 Simulate the breakthrough curve of exhaust gas to compare the adsorption effect of modified and unmodified activated carbon. When using a conventional adsorption experiment device, generally each device is equipped with 4 adsorption columns, the laboratory needs to purchase at least 4 sets of the same device, and configure 4 gas sources (gas cylinders) and at least 8 to 10 A gas composition detection instrument. To complete the experiment in a class of 32 students, in order to ensure that everyone participates in the operation, the students in the class need to be divided into two groups to conduct the experiment in turn. After the first batch of students completed the breakthrough curve test of unmodified act...

Embodiment 2

[0032] Example 2: The catalytic oxidation catalyst of NO exhaust gas is preferably developed.

[0033] Still taking the configuration of the above device as an example to describe the research process and effect of carrying out the NO exhaust gas oxidation catalyst screening activity test, and then optimizing the catalyst formulation.

[0034] A feasible technical route for smoke / exhaust gas denitrification is to partially oxidize NO into NO 2 , and then absorb and purify it with the help of wet desulfurization and denitrification equipment. Since the oxidation process of NO is very slow under low temperature and low concentration conditions, the key to this technical route is to develop efficient catalytic oxidation materials. During the research and development process, it is planned to use the impregnation method to test the catalytic activity of materials loaded with metal oxide active components on different supports.

[0035] Firstly, six kinds of metal oxides were loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com