Porous metal support type micro-tube solid oxide fuel cell and preparation method thereof

A technology of solid oxides and fuel cells, applied in the direction of fuel cells, fuel cell shapes/forms, circuits, etc., can solve the problems of complex preparation process, high cost, poor mechanical strength, etc., and achieve simple preparation process, reliable performance, Effect of system cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

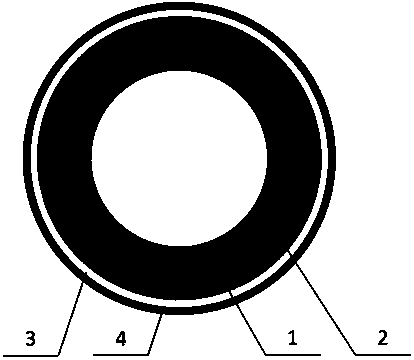

[0031] Specific Embodiment 1: This embodiment describes a porous metal-supported microtubular solid oxide fuel cell. The solid oxide fuel cell is sequentially composed of a cylindrical stainless steel microtubular support layer 1 , an anode functional layer 2, an electrolyte layer 3 and a cathode functional layer 4; the diameter of the inner circumference of the stainless steel microtube support layer 1 is 1~2.6mm, and the wall thickness is 0.2~0.6mm, and the stainless steel microtube support layer 1 has a total Divided into 3 layers, the battery structure is as figure 1 shown.

specific Embodiment approach 2

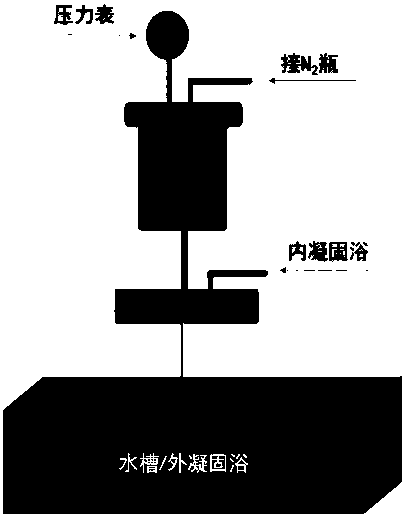

[0032] Specific embodiment two: a method for preparing the porous metal-supported microtubular solid oxide fuel cell described in specific embodiment one, the method includes the following steps:

[0033] Step 1: Preparation of slurry

[0034] (1) Metal polymer slurry: in terms of weight percentage, the content of each component is: stainless steel metal powder 61.8%, polyphenylene ether sulfone (PESf) 6.2% is a high molecular polymer, as a binder, N- Methylpyrrolidone (NMP) 27.6%, alcohol 3.1%, polyvinylpyrrolidone (PVP) 1.3%, the preparation method is as follows: weigh the raw materials and place them in a ball mill jar, and use a planetary ball mill for continuous ball milling for 48 h at a milling speed of 720 r / min to ensure that the stainless steel metal powder is uniformly dispersed in the organic solvent to obtain a uniform and stable metal-polymer slurry. The metal-polymer slurry used in the experiment should have good stability and fluidity, and have a certain visco...

specific Embodiment approach 3

[0041] Specific embodiment three: the preparation method of the porous metal-supported microtubular solid oxide fuel cell described in specific embodiment two, in step one, the material of the stainless steel metal powder is 400 series stainless steel, 300 series stainless steel, nickel Iron alloys, NiCrAlY alloys, Hastelloy-X alloys, Crofer 22APU and ITM ferritic stainless steel alloys.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com