Process for freezing and denitrating sodium chlorate mother liquor by aid of membrane methods

A technology for freezing denitration and sodium chlorate, applied in the field of electrolysis process of halogen or its compounds, can solve the problems of inability to apply sodium chlorate, inability to apply, high production cost and use cost, etc. Need, the effect of high added value of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

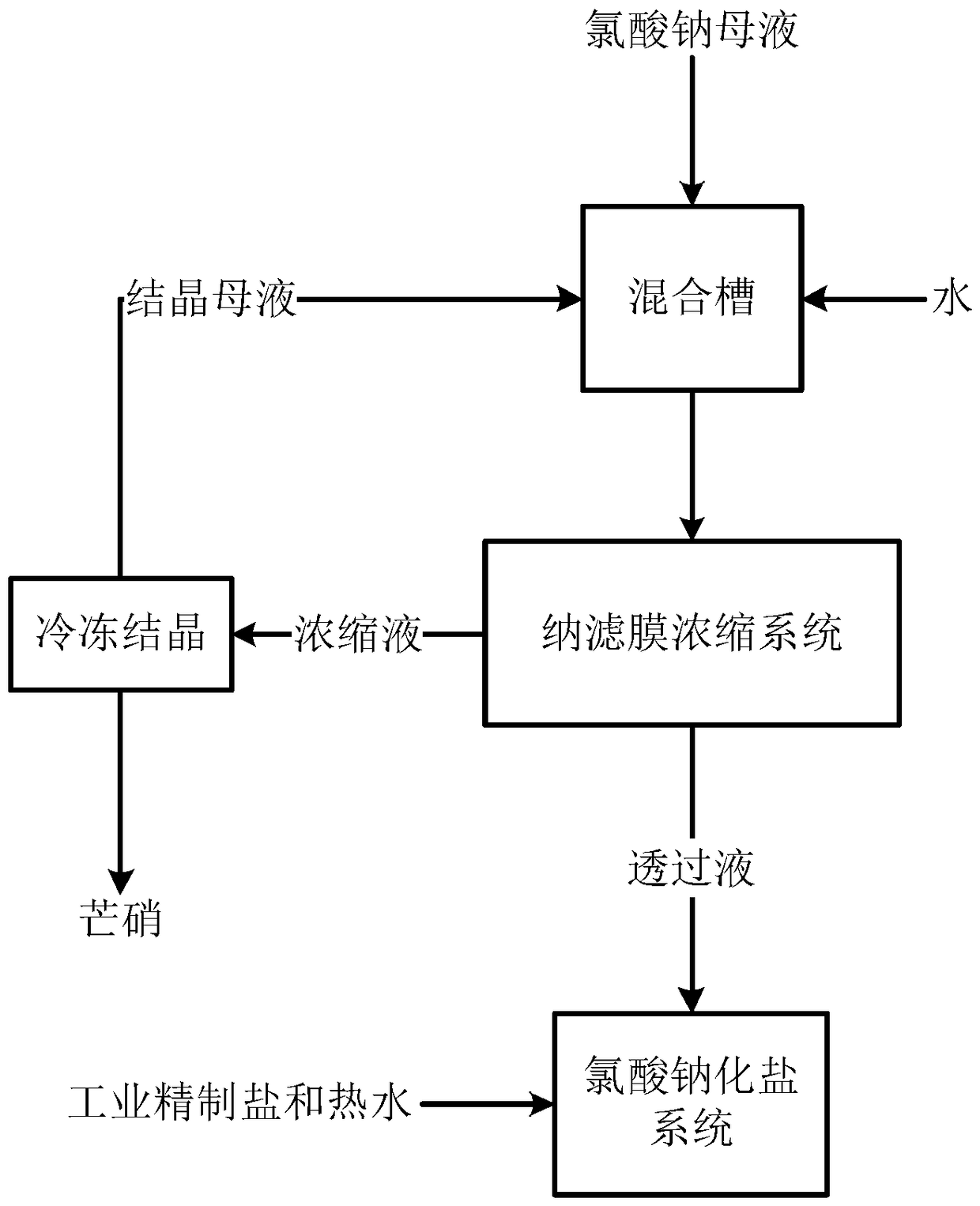

[0033] One of the embodiment of a kind of sodium chlorate mother solution membrane freezing denitrification process of the present invention, such as figure 1 , including the following steps:

[0034] (1) Dilution: Dilute the sodium chlorate mother liquor with water in the mixing tank so that the sodium chlorate concentration is lower than 200 g / L to obtain a sodium chlorate dilution; the sodium chlorate mother liquor comes out of the sodium chlorate electrolytic cell After the electrolyte solution is evaporated and crystallized, the mother liquor after centrifuge separation is a saturated solution of sodium chlorate at 40°C;

[0035] (2) Pretreatment: coarse filtration of sodium chlorate dilution, pH adjustment, dechlorination (adding Na 2 SO 3 Removal of free chlorine), pretreatment of fine filtration to obtain sodium chlorate pretreatment solution;

[0036] (3) Concentration: The sodium chlorate pretreatment liquid enters the nanofiltration membrane concentration system...

Embodiment 2

[0045] One of the embodiment of a kind of sodium chlorate mother liquid membrane freezing denitrification process of the present invention, the main technical scheme of this embodiment 2 is basically the same as that of embodiment 1, and the features not explained in this embodiment 2 are adopted in embodiment The explanation in 1 will not be repeated here. The difference between this example and Example 1 lies in: Step (1) Dilute the sodium chlorate mother liquor with water to make the sodium chlorate concentration 150 g / L. The volume ratio of sodium chlorate mother liquor to added water is 1:3.

[0046] Specifically, sodium chlorate mother liquor (consisting of sodium chloride concentration 120g / L, sodium sulfate concentration 15 g / L, sodium chlorate concentration 600g / L), 1 m 3 / h (45°C), add process water 3m into the mixing tank 3 / h, and centrifuge crystallization mother liquor (composed of sodium chloride concentration 30g / L, sodium sulfate concentration 17.5 g / L, sodi...

Embodiment 3

[0048] One of the embodiment of a kind of sodium chlorate mother liquor membrane freezing denitrification process of the present invention, the main technical scheme of the present embodiment 3 is basically the same as that of the embodiment 2, and the features not explained in the present embodiment 3 are adopted in the embodiment The explanation in 2 will not be repeated here. The difference between this example and Example 2 lies in: Step (1) Dilute the sodium chlorate mother liquor with water, so that the concentration of sodium chlorate is 117.6g / L. The volume ratio of sodium chlorate mother liquor to added water is 1:4.

[0049] Specifically, sodium chlorate mother liquor (consisting of sodium chloride concentration 120g / L, sodium sulfate concentration 15 g / L, sodium chlorate concentration 600g / L), 1 m 3 / h (45°C), add process water 4m into the mixing tank 3 / h, and the centrifuge crystallization mother liquor (composed of sodium chloride concentration 24g / L, sodium su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com