Preparation method of sulfur-doped carbon quantum dot

A technology of carbon quantum dots and sulfur doping, applied in the direction of nano-carbon, nanotechnology, etc., can solve the problems of expensive preparation process and cumbersome carbon source materials, and achieve the effects of large-scale preparation, good repeatability and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

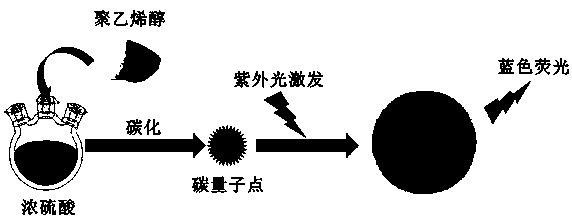

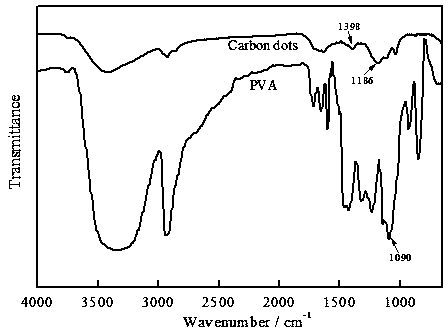

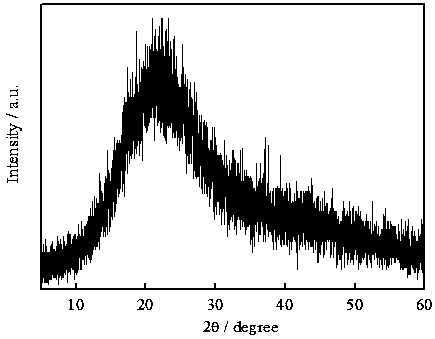

[0020] Embodiment 1: with molecular weight being 75000, polyvinyl alcohol that alcoholysis degree is 99% is carbon source material, prepares carbon quantum dot, steps are as follows:

[0021] Step 1, preparation of carbon quantum dots: place polyvinyl alcohol with a molecular weight of 75,000 and a degree of alcoholysis of 99% in a vacuum oven at a temperature of 60°C for 24 hours; disperse the dried polyvinyl alcohol into concentrated sulfuric acid Prepare a dispersion liquid with a concentration of 1g / L in the mixture, mechanically stir at a temperature of 60°C and a rotational speed of 200rpm and continue to react for 6h to obtain a concentrated sulfuric acid dispersion of carbides, which is marked as product A;

[0022] Step 2. Washing and purification of carbon quantum dots: After diluting product A with deionized water (the mass ratio of product A to deionized water is 1:10), let it stand for 12 hours. The sulfuric acid dispersion of the obtained carbide was filtered and...

Embodiment 2

[0024] Embodiment 2: with the molecular weight being 70000, alcoholysis degree being the carboxyl modified polyvinyl alcohol of 88% as carbon source material, preparing carbon quantum dots, the steps are as follows:

[0025] Step 1, preparation of carbon quantum dots: place carboxylated polyvinyl alcohol with a molecular weight of 70,000 and a degree of alcoholysis of 88% in a vacuum oven at a temperature of 60°C for 24 hours; disperse the dried polyvinyl alcohol into Prepare a dispersion liquid with a concentration of 1 g / L in concentrated sulfuric acid, mechanically stir at a temperature of 60°C and a rotational speed of 200 rpm, and continue to react for 6 hours to obtain a concentrated sulfuric acid dispersion liquid of carbides, which is marked as product A;

[0026] Step 2. Washing and purification of carbon quantum dots: After diluting product A with deionized water (the mass ratio of product A to deionized water is 1:10), let it stand for 12 hours. The sulfuric acid di...

Embodiment 3

[0028] Embodiment 3: with molecular weight being 25000, alcoholysis degree is the polyvinyl alcohol modified by sulfonic acid group of 88% as carbon source material, prepares carbon quantum dots, and the steps are as follows:

[0029] Step 1, preparation of carbon quantum dots: placing sulfonated polyvinyl alcohol with a molecular weight of 25,000 and a degree of alcoholysis of 88% in a vacuum drying oven at a temperature of 60°C for 24 hours; dispersing the dried polyvinyl alcohol into Prepare a dispersion liquid with a concentration of 1 g / L in concentrated sulfuric acid, mechanically stir at a temperature of 60°C and a rotational speed of 200 rpm, and continue to react for 6 hours to obtain a concentrated sulfuric acid dispersion liquid of carbides, which is marked as product A;

[0030] Step 2. Washing and purification of carbon quantum dots: After diluting product A with deionized water (the mass ratio of product A to deionized water is 1:10), let it stand for 12 hours. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com