Imidazole ionic liquid, ionic liquid electrolyte as well as preparation method and application thereof

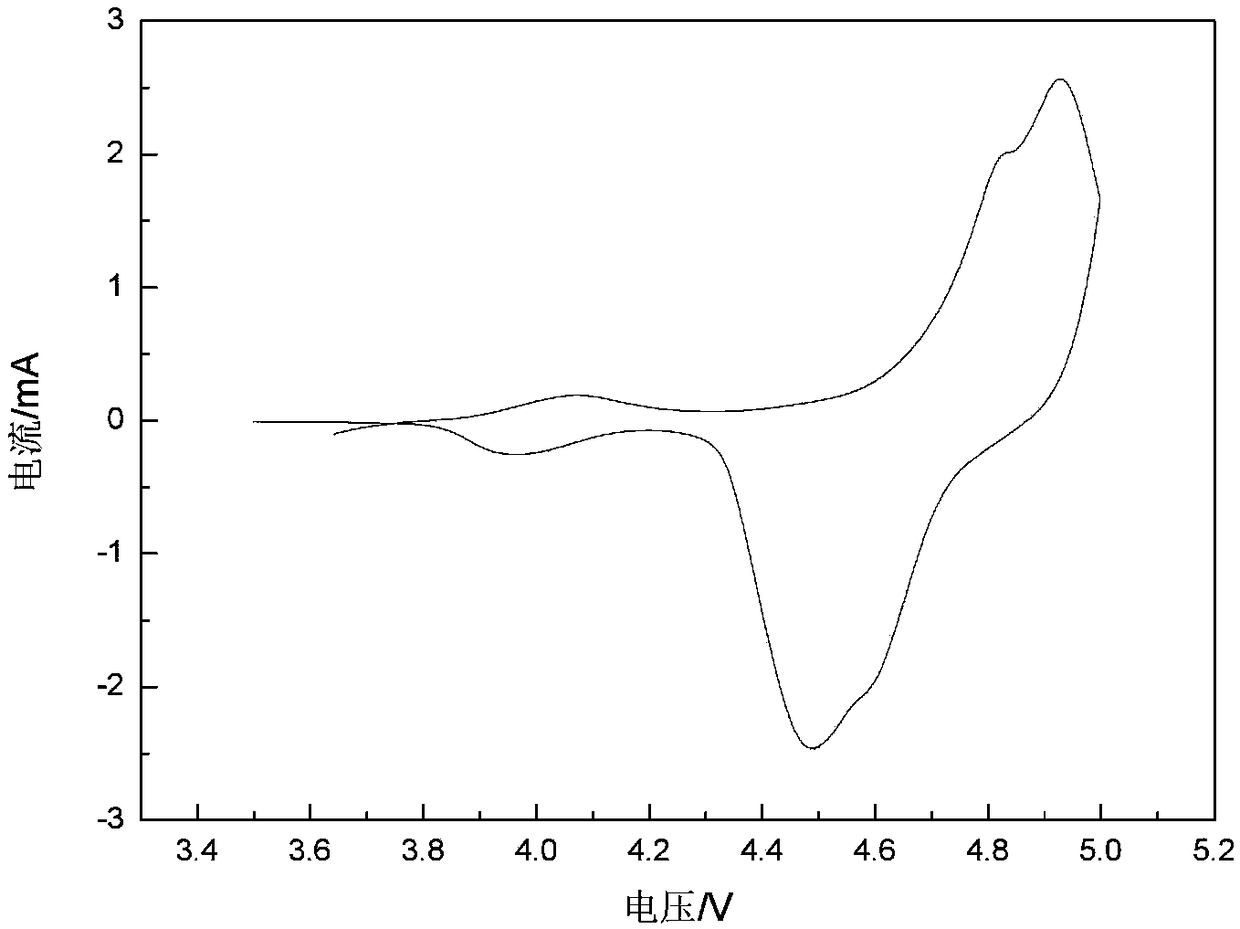

A technology of ionic liquids and imidazoles, which is applied in the electrolyte of high-voltage lithium-ion batteries. In the field of imidazoles ionic liquids, it can solve the problems of deteriorating battery performance and increasing interface impedance, achieving good safety, improving cycle performance, and wide range. The effect of the electrochemical window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] In addition, this embodiment also provides a method for preparing an imidazole-based ionic liquid, comprising the following steps:

[0058] Step S110, according to the molar ratio of 2-methylimidazole and chloroalkyl ether in the ratio of 1:1 to 1:1.1, react 2-methylimidazole and chloroalkyl ether at 100-150°C for 24~ After washing, add triethylamine in an equimolar amount to 2-methylimidazole, and react at 100-130°C for 16-24 hours to obtain 1-alkoxyalkyl-2-methylimidazole with the following structural formula:

[0059]

[0060] Among them, R 1 for CH 2 (CH 2 ) a O(CH 2 ) b CH 3 , a is 0 or 1, and b is 0 or 1.

[0061] The obtained product containing 1-alkoxyalkyl-2-methylimidazole was washed 2 to 3 times with absolute ethanol, then subjected to vacuum distillation and collected fractions to obtain purified 1-alkoxyalkyl-2 - Methylimidazole.

[0062] In other preferred embodiments, the molar ratio of 2-methylimidazole to chloroalkyl ether is 1:1.05.

[006...

Embodiment 1

[0087] Get 0.5mol 2-methylimidazole, 0.525mol 2-chloroethyl methyl ether (structural formula is ) and 80ml of absolute ethanol, mixed and dissolved, and transferred into a 250ml hydrothermal kettle to react for 48h at 140°C; then use 100ml of absolute ethanol and anhydrous ether (1:4, v / v) mixed solvent to dissolve the reaction generated The brown oil was washed three times, then mixed with 0.5mol triethylamine and transferred into a 250ml hydrothermal kettle to react at 130°C for 16h; the white salt impurities generated by the reaction were removed by suction filtration, the filtrate was collected, and the filtrate was distilled under reduced pressure , Collect the fraction ie 1-methoxyethyl-2-methylimidazole. The yield was 82%.

[0088] Add 0.35mol 1-methoxyethyl-2-methylimidazole and 0.385mol chloropropene to a 100ml flask respectively to obtain a mixture; under the protection of nitrogen atmosphere, stir the above mixture at 60°C for 8h to obtain the reaction Product; w...

Embodiment 2

[0094] Take 0.5mol 2-methylimidazole, 0.525mol 2-chloroethyl ethyl ether and 80ml of absolute ethanol, mix and dissolve, transfer to a 250ml hydrothermal kettle and react at 140°C for 54h; then use 100ml of absolute ethanol and absolute Diethyl ether (1:4, v / v) mixed solvent to wash the brown oil produced by the reaction three times, then mix it with 0.5mol triethylamine and transfer it into a 250ml hydrothermal kettle to react at 130°C for 20h; remove the reaction product by suction filtration white salt impurities, the filtrate was collected, and the filtrate was distilled under reduced pressure, and the collected fraction was 1-ethoxyethyl-2-methylimidazole. The yield was 81%.

[0095] Add 0.35mol 1-ethoxyethyl-2-methylimidazole and 0.385mol vinyl chloride to a 100ml flask respectively to obtain a mixture; under the protection of nitrogen atmosphere, stir the above mixture at 60°C for 10h to obtain the reaction The product; washed three times with ether, and the reaction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com