Method for preparing water-absorbent resin from waste macromolecular polymer

A technology of high molecular polymer and water-absorbent resin, which is applied in the field of preparing water-absorbent resin by using waste high-molecular polymer, can solve the problems of cumbersome process, complex structure, low utilization rate, etc., and achieves the advantages of simple process, simplified reaction equipment and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

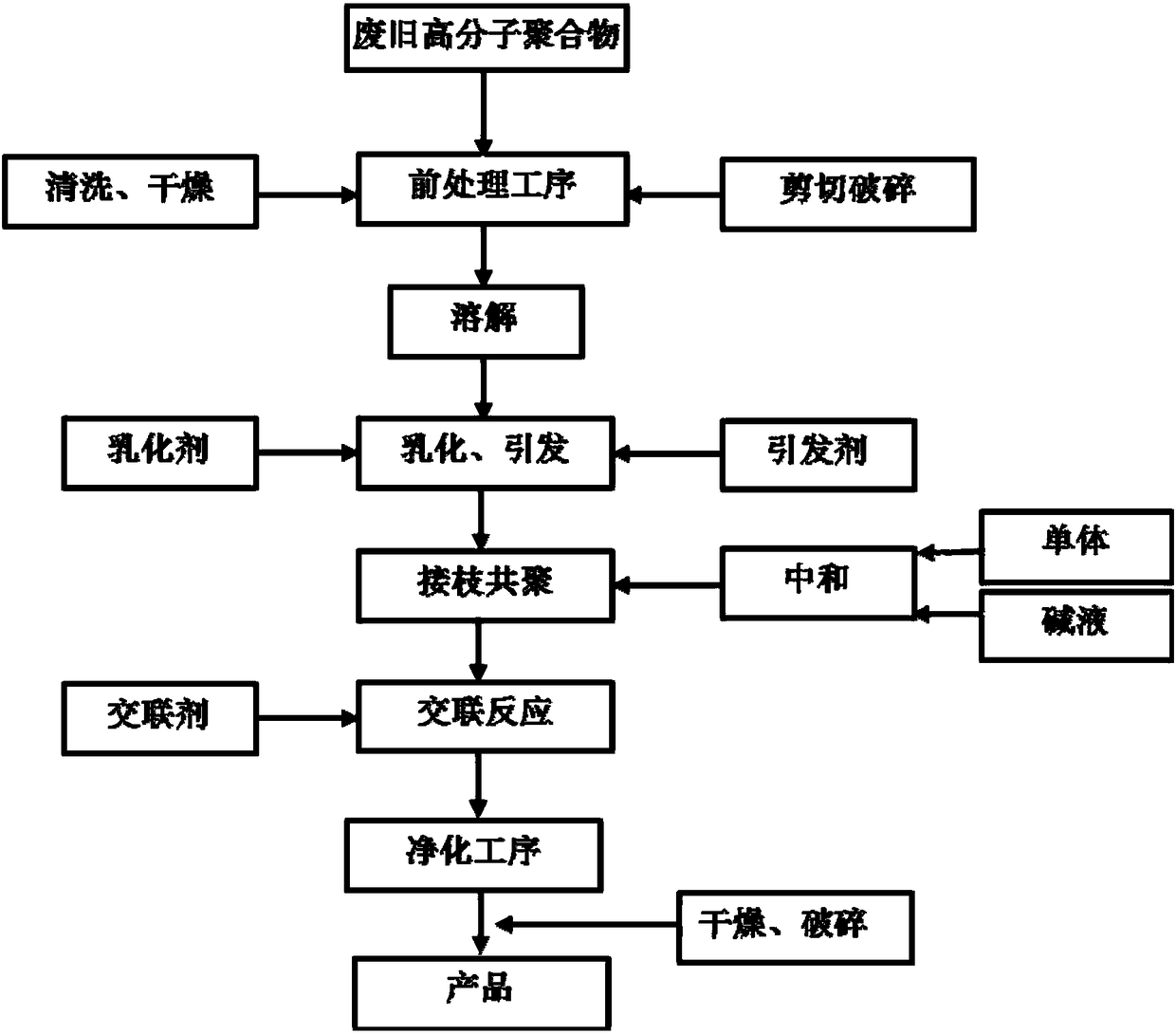

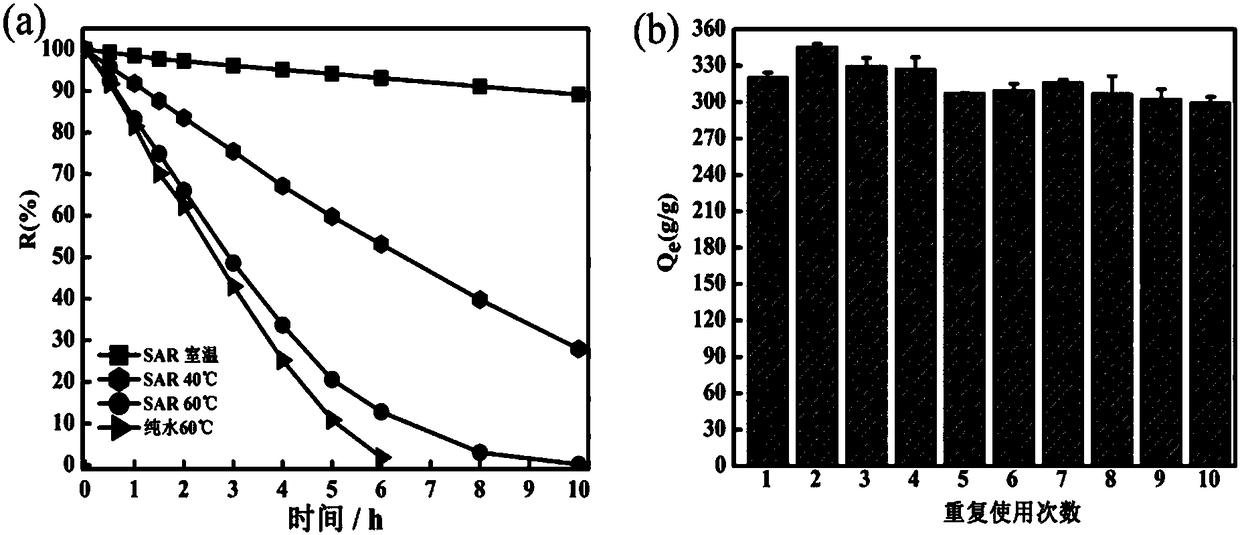

[0023] according to figure 1 Flow chart, take 1.00g of waste mixed plastic after washing, drying, shearing and crushing, and dissolve it completely in 0.02L xylene at 115°C under stirring conditions. Then add 0.30g emulsifier span60, after stirring for 10 minutes, add 0.045g initiator benzoyl peroxide dissolved in 4.20ml xylene, continue stirring for 10 minutes, and close the reaction kettle. Lower the system temperature to 95°C, then slowly add 8.00g of acrylic acid solution neutralized to 80% by NaOH dropwise, stir at 400rpm for 10 minutes, then add 1.00mL of 0.20g / mL N,N-methylenebisacrylamide solution , adjust the system oil-water volume ratio to 1.1:1.0. Continue to stir for 15 minutes, reduce the stirring speed to 200 rpm, and react for 3 hours, take out the product, wash with ethanol and water, dry at 80°C to constant weight, grind and sieve. The water absorption capacity of the product in distilled water and tap water are 239.07g / g and 97.36g / g respectively.

Embodiment 2

[0025] according to figure 1 Flowchart, take 1.00g of the above-mentioned waste mixed plastics, and dissolve them completely in 0.02L of xylene under stirring at 115°C. Then add 0.36g emulsifier span60, stir for 10 minutes, then add 0.048g initiator benzoyl peroxide dissolved in 5.22ml xylene, stir for 10 minutes, then close the reactor. When the temperature of the system drops to 95°C, slowly add 8.00 g of acrylic acid solution neutralized to 85% by NaOH dropwise, stir at 400 rpm for 10 minutes, then add 1.00 mL of 0.20 g / mL N,N-methylenebisacrylamide solution, Adjust the system oil-water volume ratio to 1.1:1.0. Continue to stir for 15 minutes, reduce the stirring speed to 250 rpm, and react for 3 hours, take out the product, wash with ethanol and water, dry at 80°C to constant weight, grind and sieve. The water absorption capacity of the product in distilled water and tap water are 310.02g / g and 116.12g / g respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com