A kind of bioactive composite material and its preparation method and application

A composite material and bioactive technology, applied in the field of bioactive composite materials and their preparation, can solve the problems of weak interaction between BG and PDC, insufficient biological activity, low mechanical properties, etc., achieve good application prospects, improve the biological phase. Capacitive, highly bioactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of PDC prepolymer

[0041] Add citric acid and 1,8-octanediol in a molar ratio of 1:0.8, with a total mass of 16.1g, into a 250ml round-bottomed flask, stir and dissolve in an oil bath at 160°C in a nitrogen atmosphere, and wait until completely dissolved , the temperature was lowered to 140° C., and the reaction was continued for 30 minutes to obtain a PDC prepolymer.

[0042] (2) Preparation of PDC-Si prepolymer

[0043] The PDC prepolymer obtained in step (1) was added to an ethanol solution containing 6.15 g of KH560 (the molar ratio of citric acid and KH560 was 1:0.5) for reaction to obtain a PDC-Si prepolymer.

[0044] (3) Preparation of citric acid-based bioactive composite materials modified by silane coupling agent

[0045] The PDC-Si prepolymer obtained in step (2) and bioactive glass particles (70% SiO 2 -30% CaO (mol.%)) is mixed according to the weight ratio of 40:60, after stirring evenly, carry out thermosetting molding at 50 ℃, obtain ...

Embodiment 2

[0048] (1) Preparation of PDC prepolymer

[0049] Add citric acid and 1,8-octanediol in a molar ratio of 1:1, with a total mass of 17.6g, into a 250ml round-bottomed flask, stir and dissolve in an oil bath at 160°C in a nitrogen atmosphere, and wait until completely dissolved Afterwards, the temperature was lowered to 140° C., and the reaction was continued for 30 minutes to obtain a PDC prepolymer.

[0050] (2) Preparation of PDC-Si prepolymer

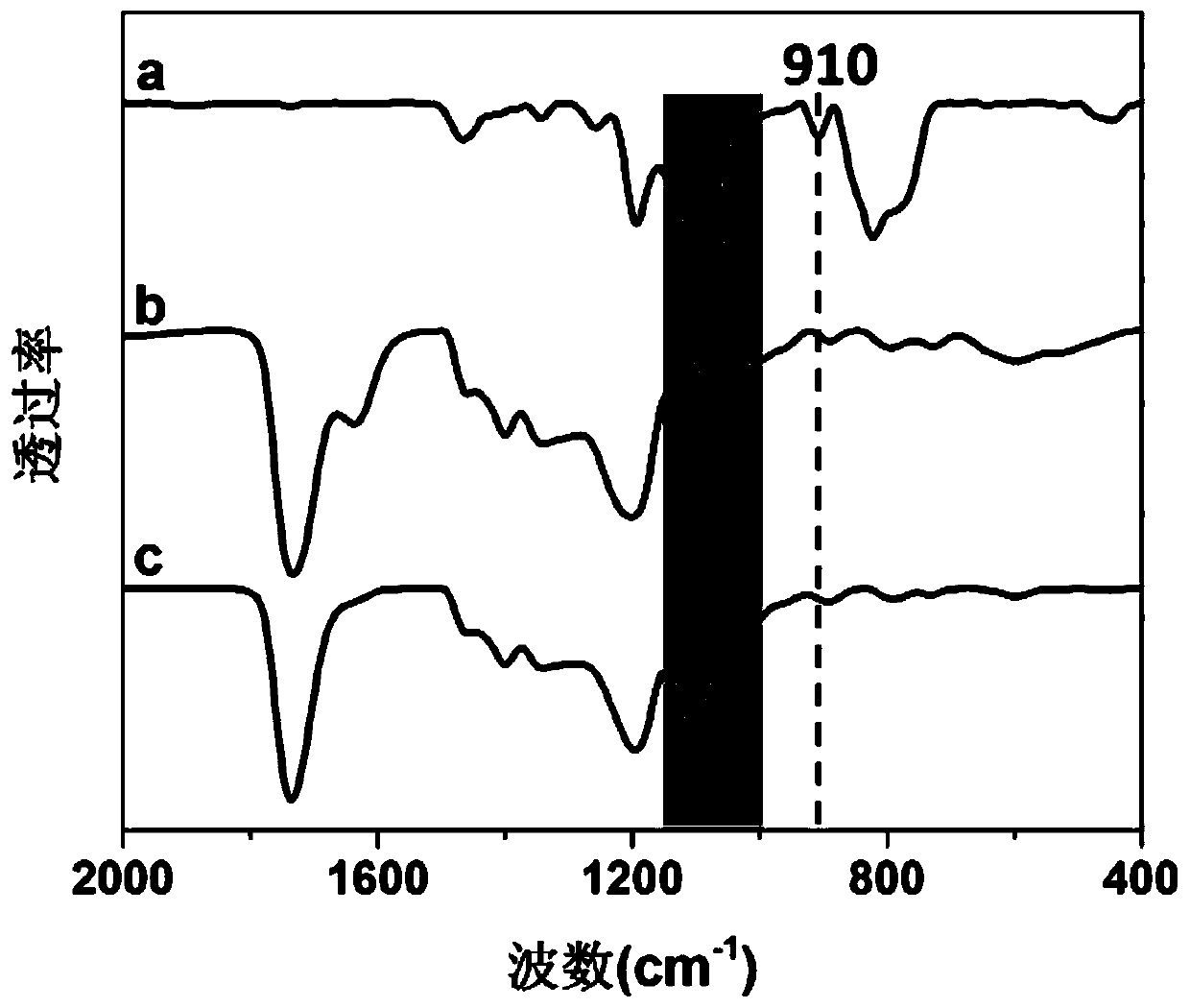

[0051] The PDC prepolymer that step (1) obtains is joined in the ethanol solution that contains 6.15g KH560 (citric acid and KH560 molar ratio are 1:0.5) carry out reaction, obtain PDC-Si prepolymer (see figure 2 ).

[0052] (3) Preparation of citric acid-based bioactive composite materials modified by silane coupling agent

[0053] The PDC-Si prepolymer obtained in step (2) and bioactive glass particles (54.2% SiO 2 -35%CaO-10.8%P 2 o 5 (mol.%)) were mixed according to the weight ratio of 50:50, stirred evenly, and then therma...

Embodiment 3

[0056] (1) With step (1) in embodiment 2.

[0057] (2) Add the PDC prepolymer obtained in step (1) to the same volume of ethanol as in Example 2 (which does not contain KH560, so that the molar ratio of citric acid and KH560 is 1:0) to obtain a PDC prepolymer.

[0058] (3) Preparation of citric acid-based bioactive composites

[0059] The PDC prepolymer obtained in step (2) and bioactive glass particles (54.2% SiO 2 -35%CaO-10.8%P 2 o 5 (mol.%)) were mixed according to the weight ratio of 50:50, and after stirring evenly, thermosetting molding was performed at 80°C to obtain a citric acid-based bioactive composite material.

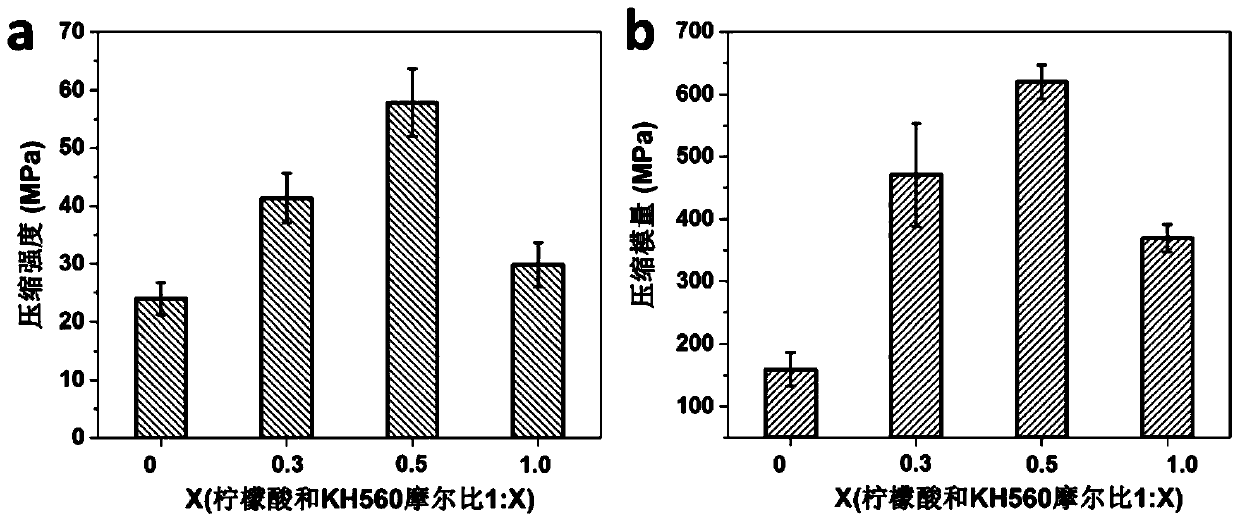

[0060] The compressive strength of the composite material measured by the universal material testing machine is 24±3MPa, and the compressive modulus is 160±27MPa (see image 3 The molar ratio of citric acid and KH560 is 1:0 group), the mechanical properties of the composite material are obviously lower than the composite material prepared in Example 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com