Process for treating waste containing arsenic, method for preparing inorganic fiber and method for recovering arsenic

A treatment process and technology of inorganic fibers, applied in the field of waste treatment, can solve the problems that silicon-based substances and calcium-based substances are not used well, unfavorable for the recycling of arsenic-containing wastes, soil pollution, etc. Expanding the effect of recycling methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a treatment process for arsenic-containing waste, comprising the following steps:

[0049] S1, heating and melting;

[0050] Mixing the arsenic-containing waste material with the inorganic raw material to obtain a first mixture, so that the mass of the calcium compound and the silicon compound in the first mixture accounts for 60-80% of the mass of the first mixture, that is, the content of calcium and silicon is 60-80%, The mass ratio of calcium and silicon in the first mixture is 1.2-1.7:1, that is, the ratio of calcium to silicon is 1.2-1.7:1. Wherein, the inorganic raw material may be high calcium stone, coal gangue and other substances.

[0051] Then the first mixture is heated at 1300-1700°C.

[0052] S2, recovery of arsenic;

[0053] Lower the temperature of the steam containing arsenic, usually to 400-500°C (that is, the first cooling), and then carry out high-temperature electrostatic dust removal.

[0054] Then, the temperature of ...

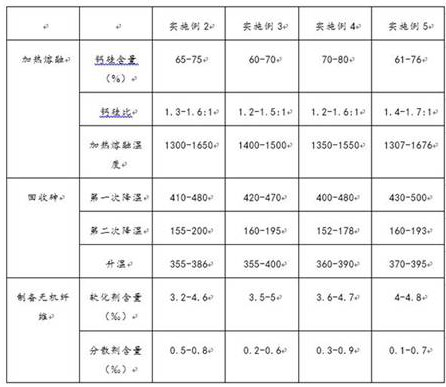

Embodiment 2-5

[0066] The operation of Embodiment 2-5 is basically the same as that of Embodiment 1, except that the operating conditions of Embodiment 2-5 are changed. Specifically, see Table 1 for the operating conditions.

[0067] The operating conditions of table 1 embodiment 2-5

[0068]

[0069] In addition, in Example 5, the limit is passed into the modification pool, and the amount of modifier added is 5-10% of the mass of the fiber to be modified. After modification, dehydration and drying are carried out.

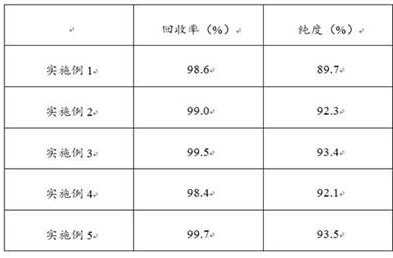

experiment example

[0071] The recovery rate and purity of the arsenic prepared in Examples 1-5 of the present invention were detected, and the detection results are shown in Table 2.

[0072] Table 2 Arsenic detection results

[0073]

[0074] According to Table 2, it can be seen that the arsenic recovered by the method provided by the embodiment of the present invention has a high recovery rate and a high purity, indicating that the arsenic recovery benefit is high and greater economic benefits are generated.

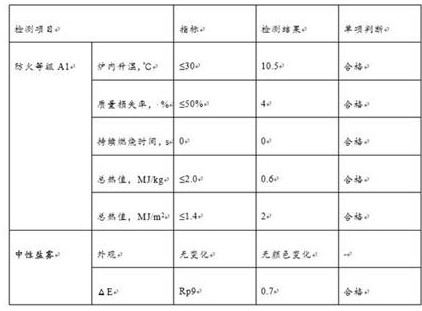

[0075] The inorganic fibers prepared in Example 1 of the present invention were tested, and the test results are shown in Table 3.

[0076] Table 3 Inorganic fiber test results

[0077]

[0078] It can be seen from Table 3 that the fiber prepared by the embodiment of the present invention has a relatively high fireproof rating and good corrosion resistance, and can be used as an industrial fireproof material.

[0079] In summary, the present invention increases the content of cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com