Application of Pd-C nano-composite material to oxidative catalysis of organic matter

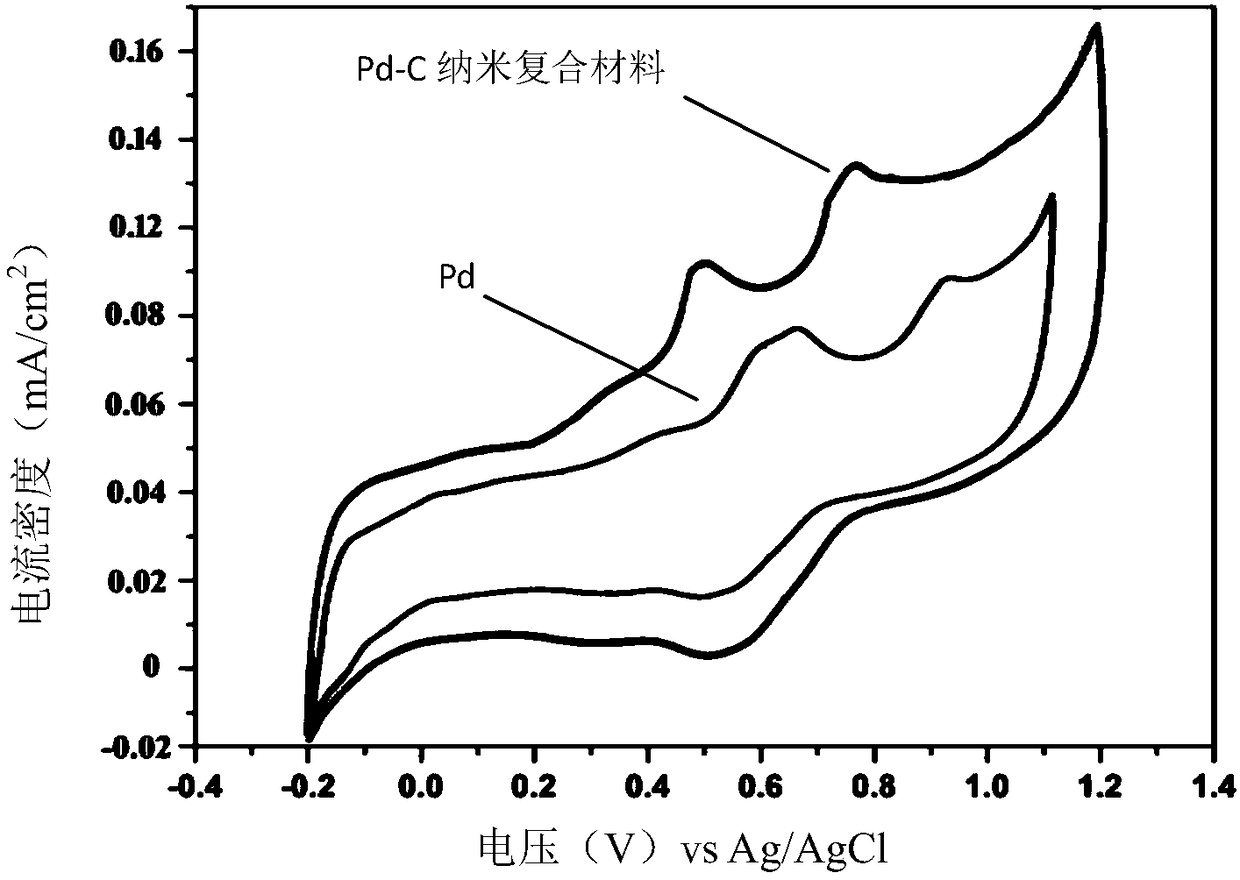

A technology of nanocomposite materials and organic matter, applied in the direction of physical/chemical process catalysts, nanotechnology, nanotechnology, etc., can solve the problem of palladium-carbon catalyst catalytic activity needs to be improved, catalytic performance and stability are not good, active ingredient loading rate is not high, etc. problem, to achieve the effect of high load rate, uniform dispersion and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

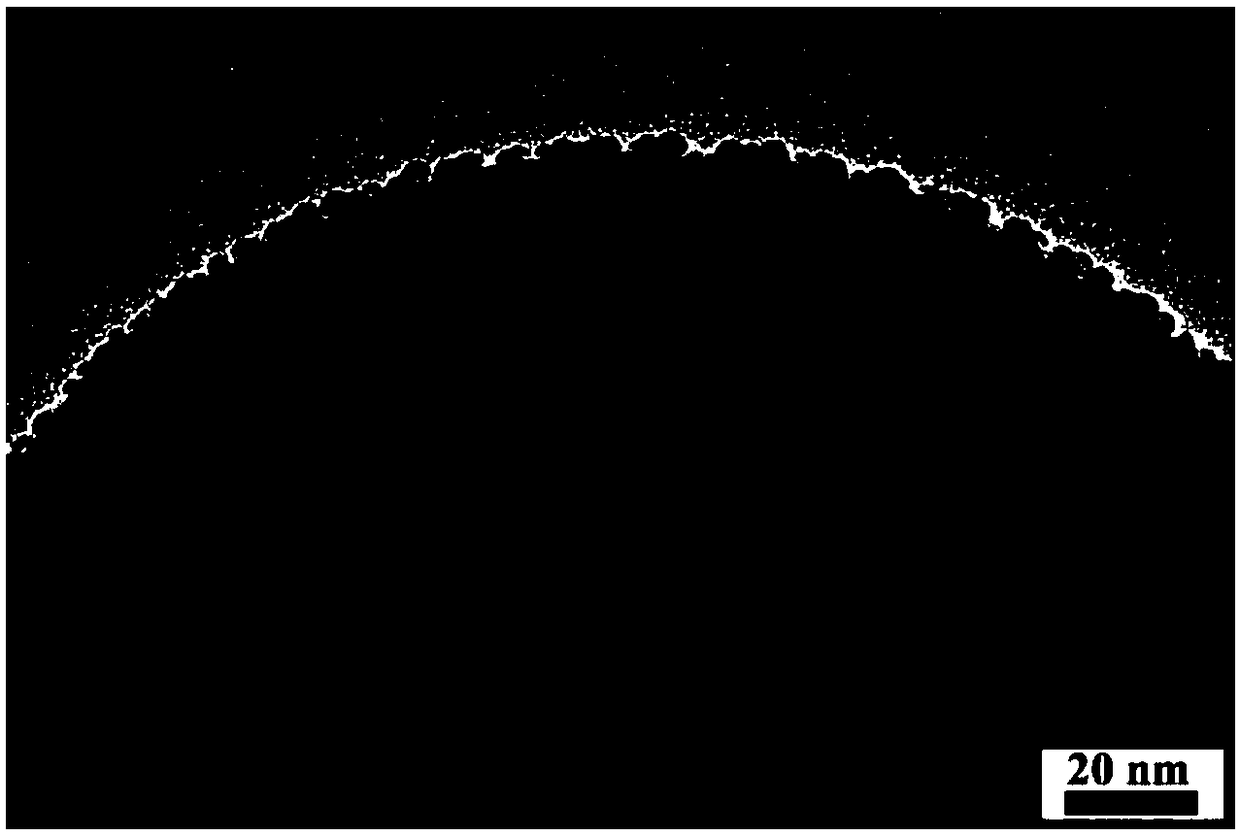

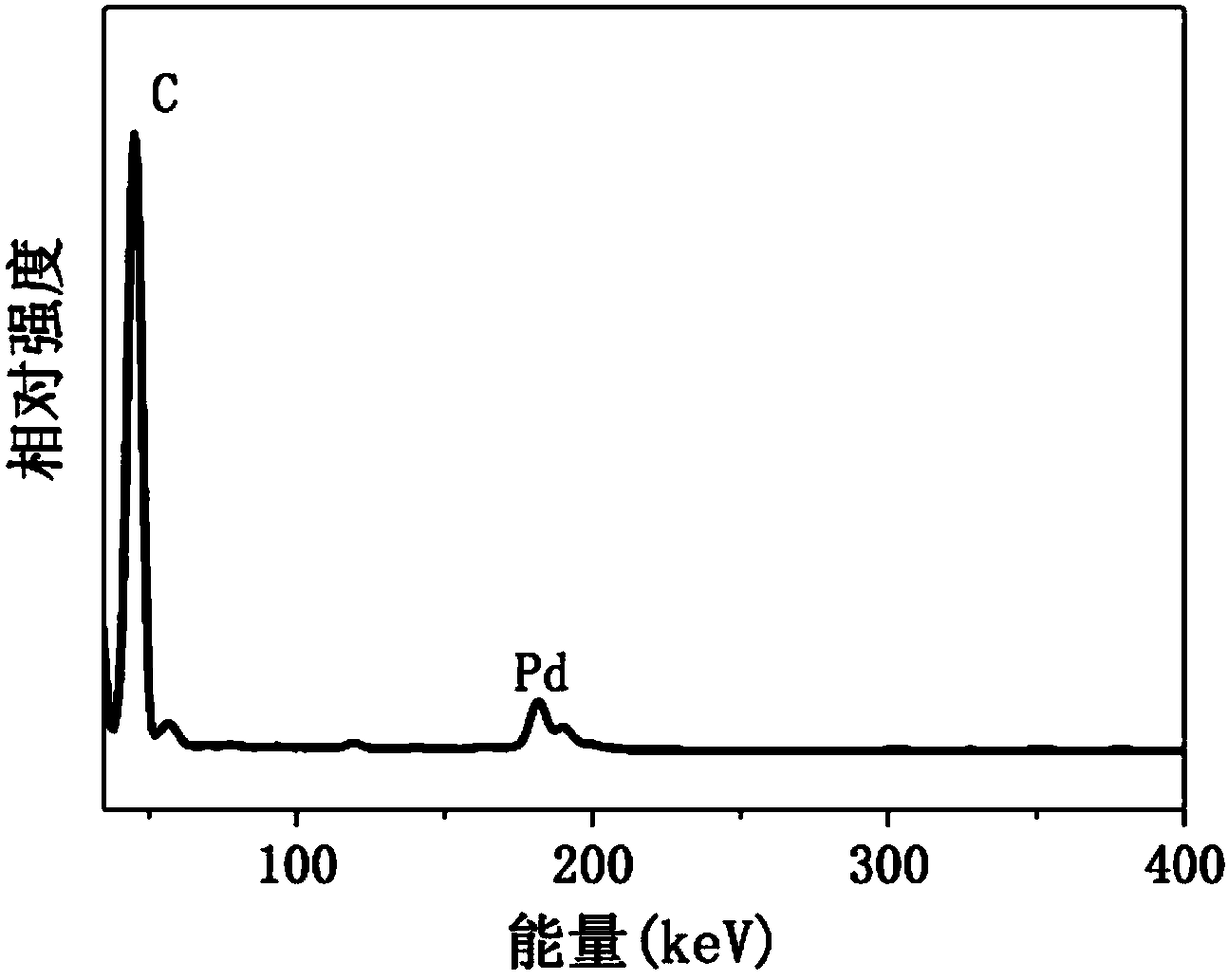

[0029] A preparation method of Pd-C nanocomposite material, comprising the following steps:

[0030] (1) Dissolve 3g of carbon source material (sucrose) in 150g of water, heat to 70°C and stir to disperse evenly, add 0.3g of stabilizer (polyvinylpyrrolidone) and mix evenly to obtain a mixture; place the mixture in a polytetrafluoroethylene seal In an autoclave and kept at 200°C for 10h, filtered, and dried to obtain a hydrothermal reaction product;

[0031] (2) Grinding 2.06g of the hydrothermal reaction product in an agate mortar, the dark powder of the gained is placed in a tube furnace, 2 / N 2 (The flow rate of hydrogen is 30cm 3 / min; the flow rate of nitrogen is 30cm 3 / min), heated at 350°C for 2h to obtain a spherical carbon material;

[0032] (3) Spherical carbon material is ultrasonically dispersed in water to obtain a 1.0wt% suspension; under vigorous stirring (600rpm), 5mL of the suspension is added dropwise to 1mL of palladium(II) acetate solution (0.005mol / L) ...

Embodiment 2

[0034] A preparation method of Pd-C nanocomposite material, comprising the following steps:

[0035] (1) Dissolve 3g of carbon source material (starch) in 150g of water, heat to 70°C, stir and disperse evenly, add 0.4g of stabilizer (hexadecylmethylammonium bromide), and mix evenly to obtain a mixture; Seal the autoclave with tetrafluoroethylene and keep it at 200°C for 10h, filter and dry to obtain the hydrothermal reaction product;

[0036] (2) 2.05g of the hydrothermal reaction product is ground in an agate mortar, and the dark powder of the gained is placed in a tube furnace, 2 / N 2 (The flow rate of hydrogen is 30cm 3 / min; the flow rate of nitrogen is 30cm 3 / min), heated at 350°C for 2h to obtain a spherical carbon material;

[0037] (3) Spherical carbon material is ultrasonically dispersed in water to obtain a 1.0wt% suspension; under vigorous stirring (600rpm), 5mL of the suspension is added dropwise to 1mL of palladium(II) acetate solution (0.005mol / L) solution ...

Embodiment 3

[0039] A preparation method of Pd-C nanocomposite material, comprising the following steps:

[0040] (1) Dissolve 2g of carbon source material (glucose) in 150g of water, heat to 70°C and stir to disperse evenly, add 0.4g of stabilizer (sodium citrate) and mix evenly to obtain a mixture; place the mixture in a polytetrafluoroethylene seal In an autoclave and kept at 200°C for 10h, filtered, and dried to obtain a hydrothermal reaction product;

[0041] (2) 2g of the hydrothermal reaction product is ground in an agate mortar, and the dark powder of the gained is placed in a tube furnace, 2 / N 2 (The flow rate of hydrogen is 30cm 3 / min; the flow rate of nitrogen is 30cm 3 / min), heated at 350°C for 2h to obtain a spherical carbon material;

[0042](3) Spherical carbon material is ultrasonically dispersed in water to obtain a 1.0wt% suspension; under vigorous stirring (600rpm), 5mL of the suspension is added dropwise to 1mL of palladium(II) acetate solution (0.005mol / L) solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com