Phosphogypsum-based imitation-marble high-strength architectural decoration plate and preparing method

A technology for imitating marble and architectural decoration, applied in the field of preparation of imitation stone building materials, can solve the problems of insufficient overall improvement of imitation marble base material, slow improvement of activation degree and solidification performance, complicated preparation method of imitation marble floor, etc. And the effect of improving solidification performance, promoting solidification performance, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

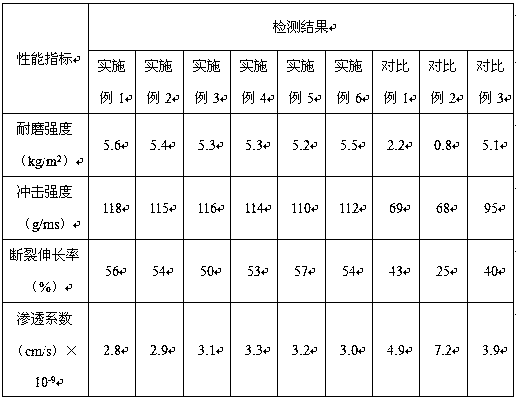

Examples

Embodiment 1

[0028] The preparation of phosphogypsum-based marble-like high-strength architectural decorative boards, the steps are as follows:

[0029] a. Grinding plant ash into nano-level fine powder with a particle size of 10-100 nm using a nano-grinding machine, and dispersing it in a fluidized device, the fluidized device includes at least one fluidized bed and a wall arranged on the fluidized bed The internal ice water circulation system is fed with water vapor at a temperature of 130°C, so that the plant ash fine powder is in full contact with the water vapor, and soaked in the water after the water vapor has condensed to form a leachate;

[0030] b. Simultaneously spray low-temperature rice husk ash with a temperature of 15° C. into the leachate prepared in step a, stir, mix evenly, quickly freeze and form, and pulverize, so that the pores on the surface of the rice husk ash are loaded with plant ash fine powder to obtain a composite powder;

[0031] c. Add 20 parts by weight of t...

Embodiment 2

[0034] The preparation of phosphogypsum-based marble-like high-strength architectural decorative boards, the steps are as follows:

[0035] a. Grinding plant ash into nano-level fine powder with a particle size of 10-100 nm using a nano-grinding machine, and dispersing it in a fluidized device, the fluidized device includes at least one fluidized bed and a wall arranged on the fluidized bed The internal ice water circulation system is fed with water vapor at a temperature of 120°C, so that the plant ash fine powder is in full contact with the water vapor, and soaked in the water after the water vapor has condensed to form a leachate;

[0036] b. Simultaneously spray low-temperature rice husk ash at a temperature of 10° C. into the leach solution prepared in step a, stir, mix evenly, quickly freeze and form, and pulverize, so that the pores on the surface of the rice husk ash are loaded with plant ash fine powder to obtain a composite powder;

[0037] c. Add 10 parts by weight ...

Embodiment 3

[0040] The preparation of phosphogypsum-based marble-like high-strength architectural decorative boards, the steps are as follows:

[0041] a. Grinding plant ash into nano-level fine powder with a particle size of 10-100 nm using a nano-grinding machine, and dispersing it in a fluidized device, the fluidized device includes at least one fluidized bed and a wall arranged on the fluidized bed The internal ice water circulation system is fed with water vapor at a temperature of 125°C, so that the plant ash fine powder is in full contact with the water vapor, and soaked in the water after the water vapor has condensed to form a leachate;

[0042] b. At the same time, spray low-temperature rice husk ash with a temperature of 18° C. into the leachate prepared in step a, stir, mix evenly, quickly freeze and form, and pulverize, so that the pores on the surface of the rice husk ash are loaded with plant ash fine powder to obtain a composite powder;

[0043] c. Add 18 parts by weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com