Nano-grade aqueous narrow molecular weight distribution acrylic acid copolyester and preparation method thereof

A narrow molecular weight distribution, acrylic copolyester technology, applied in the chemical industry, can solve the problems of VOC hazards, environmental governance difficulties, etc., and achieve the effects of strong waterproof ability, good waterproof performance, and excellent environmental protection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

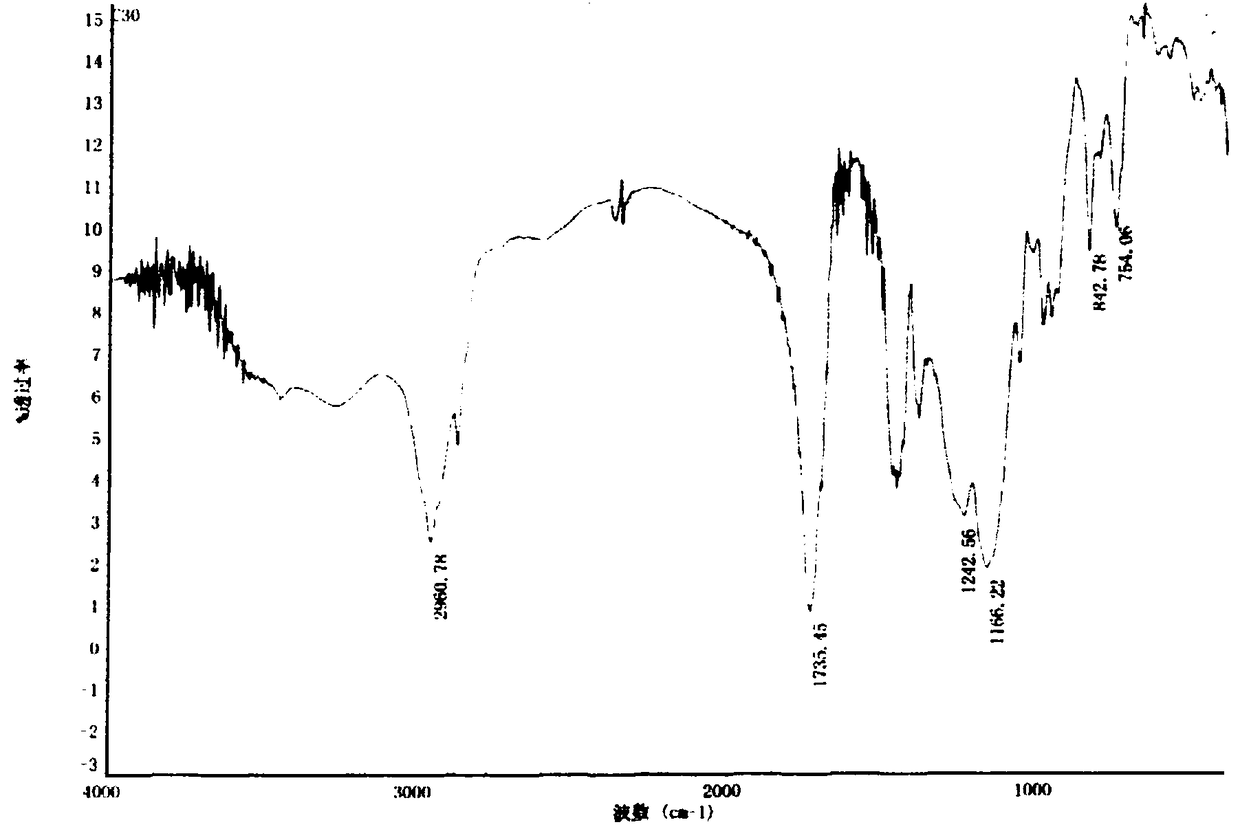

[0057] Embodiment 1, the preparation of nanoscale water-based narrow molecular weight distribution acrylic copolyester C30

[0058] The preparation method of nanoscale water-based narrow molecular weight distribution acrylic acid copolyester of the present invention is as follows:

[0059] A) Dissolve the emulsifier sodium lauryl sulfate of formula quantity 50% quality in the ultrapure water of formula quantity 90% quality in reactor, stir until sodium lauryl sulfate dissolves completely, form emulsifier aqueous solution, then heat to 80°C and maintain a constant temperature.

[0060] B) add the water of remaining formula quantity in the container, then add the initiator ammonium persulfate of formula quantity, stir until ammonium persulfate dissolves completely, obtain initiator aqueous solution.

[0061] C) Add the basic monomer methyl methacrylate, methacrylic acid and butyl acrylate of the recipe amount into the container respectively, stir evenly, remove the polymeriza...

Embodiment 2

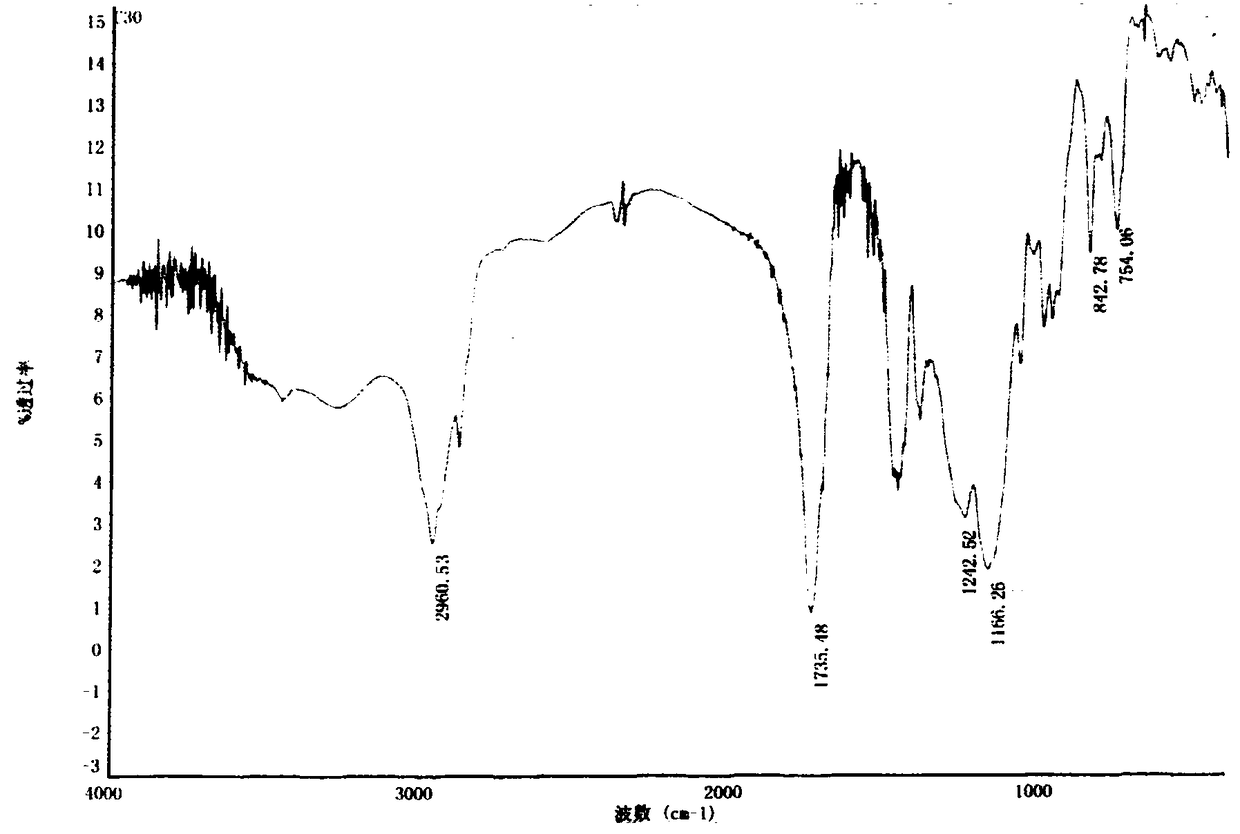

[0064] Embodiment 2, preparation of nanoscale water-based narrow molecular weight distribution acrylic copolyester C30

[0065] A) in the reactor, dissolve the emulsifier sodium octadecyl sulfate of formula amount 45% quality with the ultrapure water of formula amount 80% quality, stir until sodium octadecyl sulfate dissolves completely, form emulsifier aqueous solution, then heat to 70°C and maintain a constant temperature.

[0066] B) add the water of remaining formula quantity in the container, then add the initiator potassium persulfate of formula quantity, stir until potassium persulfate dissolves completely, obtain initiator aqueous solution;

[0067] C) Add the basic monomer methyl methacrylate, methacrylic acid and butyl acrylate of the recipe amount into the container respectively, stir evenly, remove the polymerization inhibitor, and add the emulsifier of the remaining recipe amount of 55% by mass, and stir slowly Until the emulsifier and basic monomer are complet...

Embodiment 3

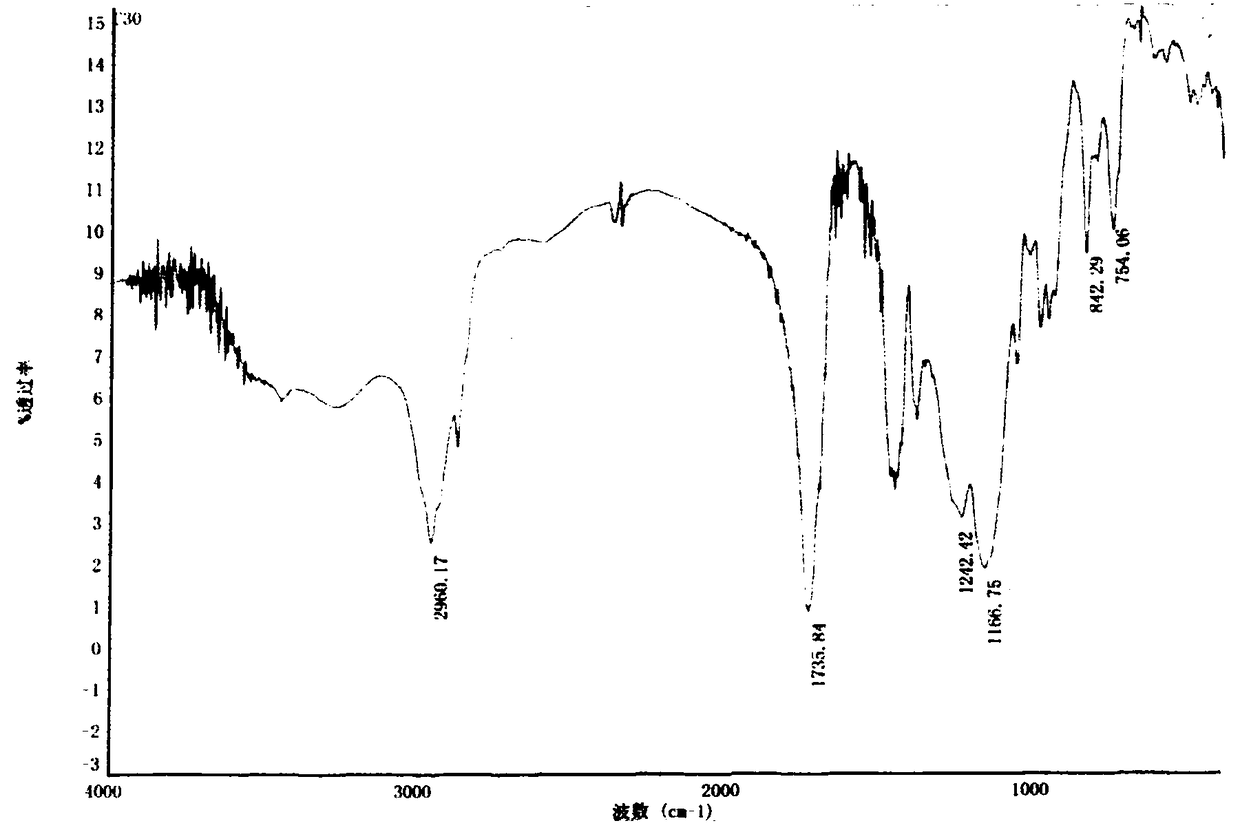

[0069] Embodiment 3, preparation of nanoscale water-based narrow molecular weight distribution acrylic copolyester C30

[0070] A) Dissolve emulsifier NP-10 with a formula quantity of 55% mass in ultrapure water with a formula quantity of 70% mass in the reactor, stir until the NP-10 is completely dissolved to form an aqueous emulsifier solution, then heat to 85°C and keep constant temperature.

[0071] B) add the water of remaining formula quantity in the container, then add the initiator ammonium persulfate of formula quantity, stir until ammonium persulfate dissolves completely, obtain initiator aqueous solution;

[0072] C) Add the basic monomers methyl methacrylate, methacrylic acid and butyl acrylate of the recipe amount into the container respectively, stir evenly, remove the polymerization inhibitor, and add the emulsifier of the remaining recipe amount of 45% by mass, and stir slowly Until the emulsifier and basic monomer are completely dissolved to obtain a mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com