Micro cutting fluid capable of reducing corrosion of metal material and preparation method thereof

A metal material and cutting fluid technology, applied in the field of micro cutting fluid and its preparation, can solve the problems affecting the health of operators, pollution, waste of resources, etc., and achieve good biodegradability, good biodegradability, and good anti-corrosion effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Put 900g of ricinoleic acid and 100g of praseodymium oxide into a stirrer, and stir and react at 100°C for 4 hours to form castor oil praseodymium salt, which is used as a trace cutting fluid precursor.

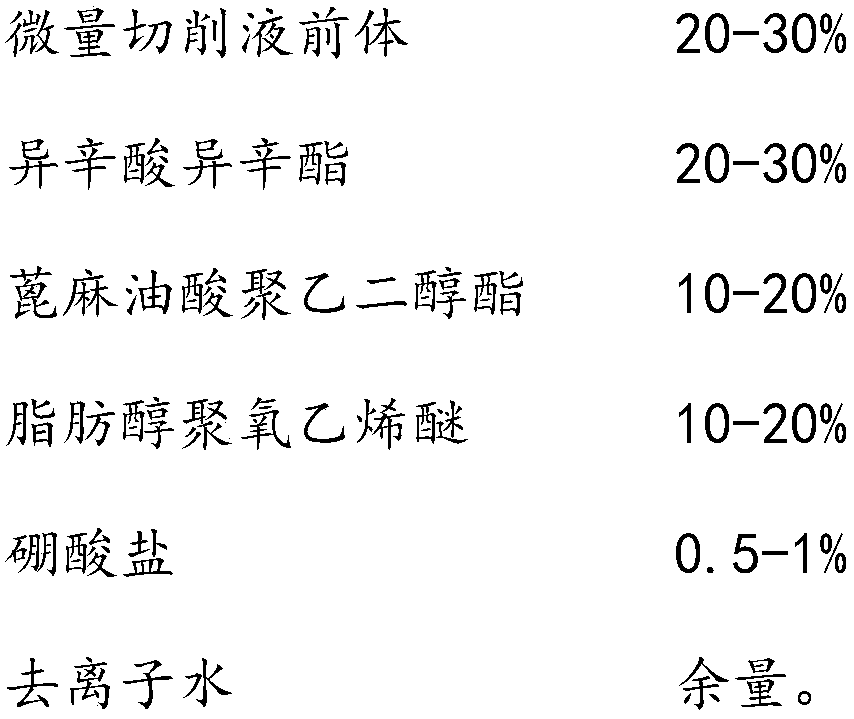

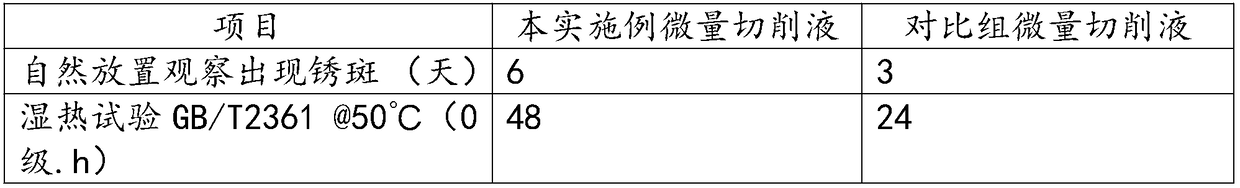

[0036] Take by weighing above-mentioned trace lubricating oil precursor 300g, isooctyl isooctanoate 200g, polyethylene glycol ricinoleate 150g, fatty alcohol polyoxyethylene ether (AEO-9) 150g, 200g potassium tetraborate solution (10g tetraboric acid Potassium is pre-dissolved in 190g deionized water) and mixed and stirred at a temperature of 50°C until it is transparent, it is a kind of cutting fluid that can reduce the corrosion of metal materials.

[0037] The preparation method of above-mentioned Polyethylene Glycol Ricinoleate is:

[0038] Step 1: Put 500g ricinoleic acid, 750g polyethylene glycol (PEG-400) and catalyst (4g isopropyl titanate) into the polymerization kettle respectively;

[0039] Step 2: Filling with nitrogen to replace the air in the polymerizat...

Embodiment 2

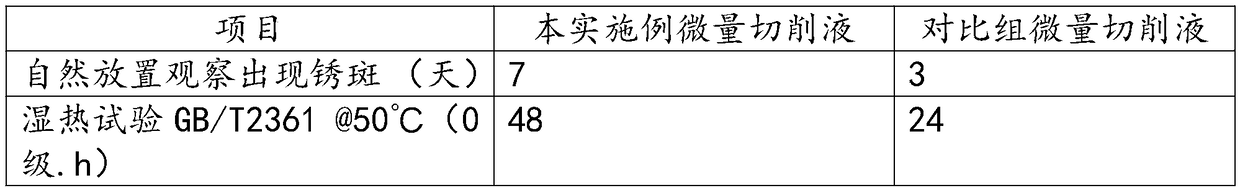

[0045] Put 850g of ricinoleic acid and 150g of praseodymium oxide into a stirrer, and stir and react at a temperature of 110°C for 3 hours to form castor oil praseodymium salt, which is used as a trace cutting fluid precursor.

[0046] Take by weighing above-mentioned trace amount lubricating oil precursor 250g, isooctyl isooctyl 250g, polyethylene glycol ricinoleate 200g, fatty alcohol polyoxyethylene ether (AEO-10) 100g, 200g sodium tetraborate solution (5g tetraboric acid Potassium is pre-dissolved in 195g deionized water) and mixed and stirred at a temperature of 60°C until it is transparent, it is a kind of cutting fluid that can reduce the corrosion of metal materials.

[0047] The preparation method of above-mentioned Polyethylene Glycol Ricinoleate is:

[0048] Step 1: 500g ricinoleic acid, 1000g polyethylene glycol (PEG-600) and catalyst (3g potassium perborate) are dropped into the polymerization kettle respectively;

[0049] Step 2: Filling with nitrogen to replace...

Embodiment 3

[0055] Put 860g of ricinoleic acid and 140g of praseodymium oxide into a stirrer, and stir and react at a temperature of 90°C for 4 hours to form castor oil praseodymium salt, which is used as a trace cutting fluid precursor.

[0056] Take by weighing above-mentioned trace lubricating oil precursor 200g, isooctyl isooctyl isooctyl 300g, polyethylene glycol ricinoleate 100g, fatty alcohol polyoxyethylene ether (AEO-12) 200g, 200g potassium metaborate solution (8g metaboric acid Potassium is pre-dissolved in 192g deionized water) and mixed and stirred at a temperature of 40°C until it is transparent, it is a kind of cutting fluid that can reduce the corrosion of metal materials.

[0057] The preparation method of above-mentioned Polyethylene Glycol Ricinoleate is:

[0058]Step 1: 500g ricinoleic acid, 500g polyethylene glycol (PEG-200) and catalyst (4g sodium perborate) are dropped into the polymerization kettle respectively;

[0059] Step 2: Filling with nitrogen to replace th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com