Sodium-ion battery positive electrode material, preparation method thereof and sodium-ion battery

A sodium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that cannot be used in sodium batteries, achieve excellent specific capacity and cycle performance, convenient operation, and environmentally friendly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

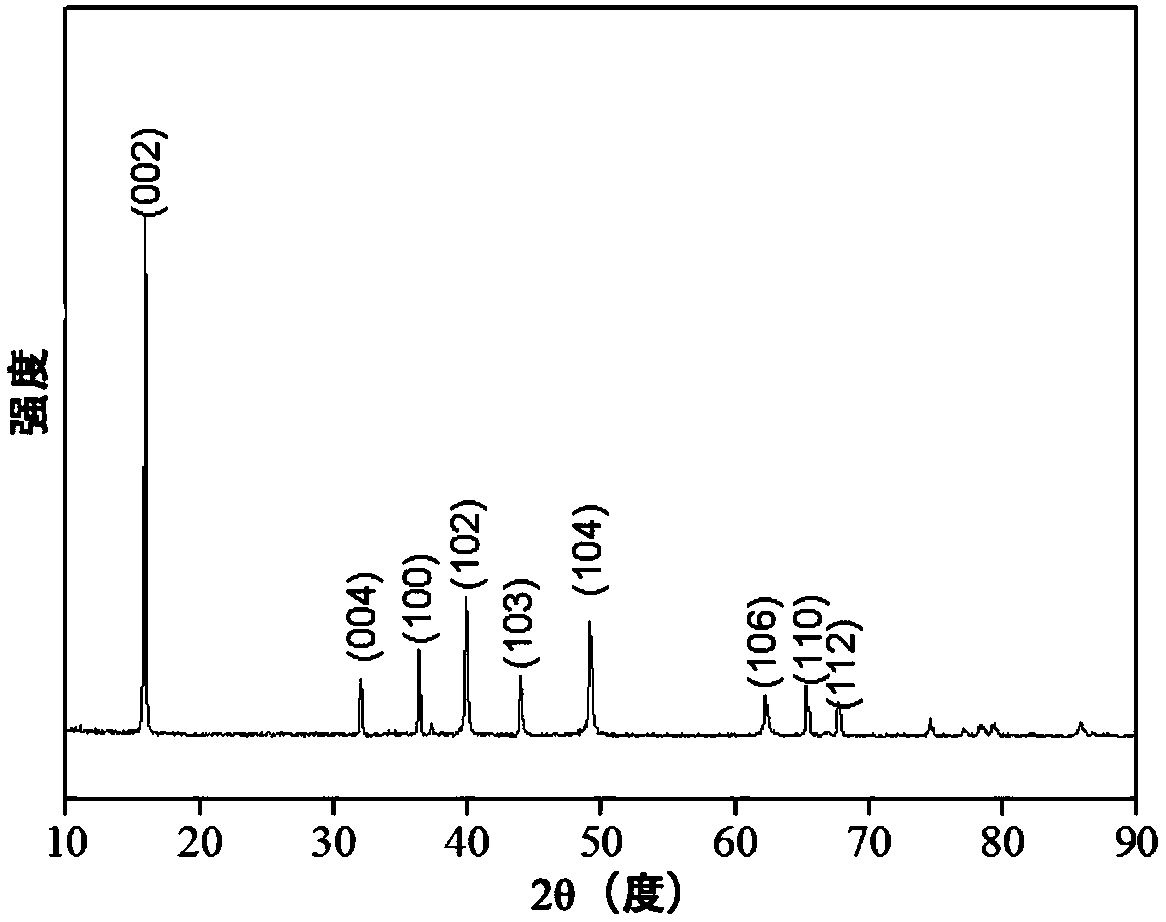

Embodiment 1

[0076] The present embodiment adopts the following method to prepare the positive electrode material of sodium ion battery:

[0077] (1) Na 2 CO 3 Fully dissolve 0.3mol / L ammonia water in deionized water to obtain an alkaline solution, mix it with a mixed metal salt solution containing nickel salt, cobalt salt and manganese salt, carry out a co-precipitation reaction at 50°C, and add the manganese salt solution dropwise to the co-precipitation reaction In the precipitation reaction system, the pH of the coprecipitation reaction system controlled by the flow rate of the alkali solution is 7.5, and the mol ratio of the nickel element, cobalt element and manganese element in the coprecipitation reaction system is 1.67:1.67:6.7, suction filtration, to The obtained solid is dried and sieved to obtain mixed metal carbonate;

[0078] Wherein, the Na in the alkaline solution 2 CO 3 The solute mass ratio to ammonia water is 13:1, and the nickel salt is NiSO 4 , the cobalt salt is ...

Embodiment 2

[0088] The present embodiment adopts the following method to prepare the positive electrode material of sodium ion battery:

[0089] (1) Na 2 CO 3 Fully dissolve 0.3mol / L ammonia water in deionized water to obtain an alkaline solution, mix it with a mixed metal salt solution containing nickel salt, cobalt salt and manganese salt, carry out a co-precipitation reaction at 50°C, and add the manganese salt solution dropwise to the co-precipitation reaction In the precipitation reaction system, the pH of the coprecipitation reaction system controlled by the flow rate of the alkali solution is 7.8, and the mol ratio of the nickel element, cobalt element and manganese element in the coprecipitation reaction system is 1.67:1.67:6.7, suction filtration, to The obtained solid is dried and sieved to obtain mixed metal carbonate;

[0090] Wherein, the Na in the alkaline solution 2 CO 3 The solute mass ratio to ammonia water is 13:1, and the nickel salt is NiSO 4 , the cobalt salt is ...

Embodiment 3

[0100] The present embodiment adopts the following method to prepare the positive electrode material of sodium ion battery:

[0101] (1) Na 2 CO 3 Fully dissolve 0.3mol / L ammonia water in deionized water to obtain an alkaline solution, mix it with a mixed metal salt solution containing nickel salt, cobalt salt and manganese salt, carry out a co-precipitation reaction at 50°C, and add the manganese salt solution dropwise to the co-precipitation reaction In the precipitation reaction system, the pH of the coprecipitation reaction system controlled by the flow rate of the alkali solution is 8.2, and the mol ratio of the nickel element, cobalt element and manganese element in the coprecipitation reaction system is 1.67:1.67:6.7, suction filtration, to The obtained solid is dried and sieved to obtain mixed metal carbonate;

[0102] Wherein, the Na in the alkaline solution 2 CO 3 The solute mass ratio to ammonia water is 13:1, and the nickel salt is NiSO 4 , the cobalt salt is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com