Coal-based solid acid catalyst and preparation method thereof

A solid acid catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of high cost and small specific surface area, and achieve low production cost, high activity and easy separation The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

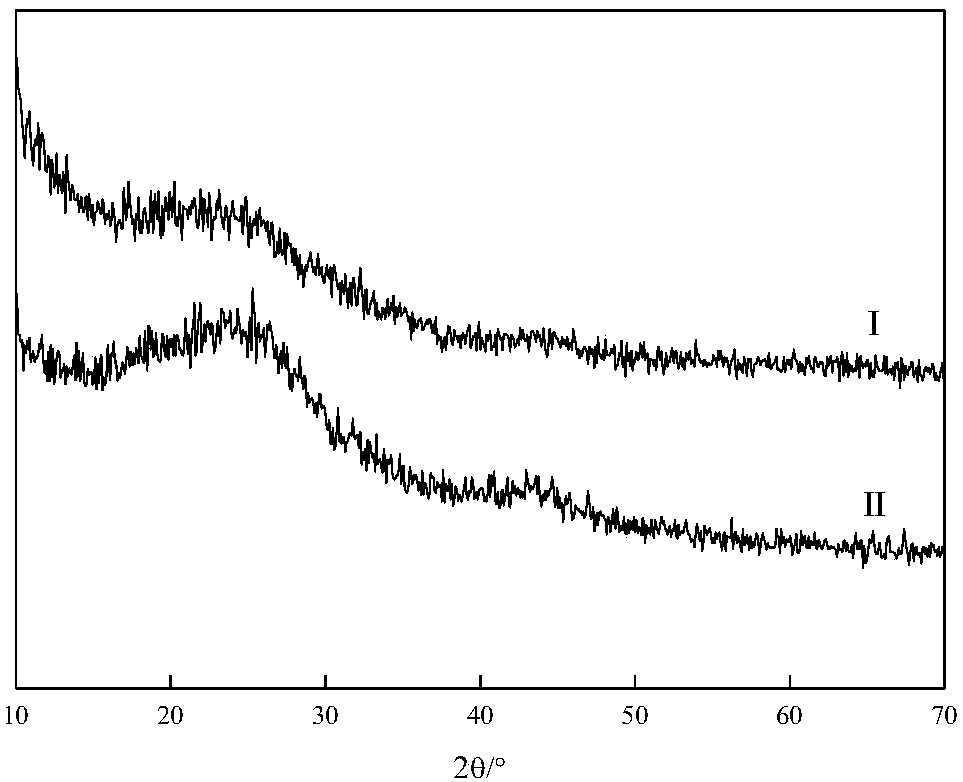

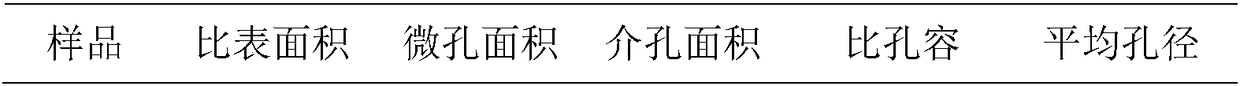

Image

Examples

Embodiment 1

[0046] 1, a kind of preparation method of coal-based solid acid catalyst, comprises the steps:

[0047] 1) Grind and sieve the Yulin coal to 200 mesh, and dry it in a blast drying oven at 105°C for later use;

[0048] 2) Mix 6 g of the coal powder obtained by drying in step 1) with 18 g of potassium hydroxide solid powder, and activate it at 800° C. for 90 minutes in a nitrogen protective atmosphere to obtain an activated product;

[0049] 3) Wash the activated product obtained in step 2) with 0.5mol / L hydrochloric acid until it is acidic, and stir it magnetically for 2 hours to ensure that it is fully dissolved, then wash and filter until the product is neutral and no chloride ions are detected, then bake at 105°C overnight dry to obtain activated carbon;

[0050] 4) Add 1.5g of activated carbon and 12g of p-aminobenzenesulfonic acid obtained in step 3) into 200ml of deionized water and mix, and place the mixed solution in an oil bath at 60°C with magnetic force stirring, th...

Embodiment 2

[0055] 1, a kind of preparation method of coal-based solid acid catalyst, comprises the steps:

[0056] 1) Grind and sieve the Yulin coal to 200 mesh, and dry it in a blast drying oven at 105°C for later use;

[0057] 2) Mix 6 g of the coal powder obtained by drying in step 1) with 18 g of potassium hydroxide solid powder, and activate it at 900° C. for 90 minutes in a nitrogen protective atmosphere to obtain an activated product;

[0058] 3) Wash the activated product obtained in step 2) with 0.5mol / L hydrochloric acid until it is acidic, and stir it magnetically for 2 hours to ensure that it is fully dissolved, then wash and filter until the product is neutral and no chloride ions are detected, then bake at 105°C overnight dry to obtain activated carbon;

[0059] 4) Add 1.5g of activated carbon and 12g of p-aminobenzenesulfonic acid obtained in step 3) into 200ml of deionized water and mix, and place the mixed solution in an oil bath at 60°C with magnetic force stirring, th...

Embodiment 3

[0063] 1, a kind of preparation method of coal-based solid acid catalyst, comprises the steps:

[0064] 1) Grind and sieve the Yulin coal to 200 mesh, and dry it in a blast drying oven at 105°C for later use;

[0065] 2) Mix 6 g of the coal powder obtained by drying in step 1) with 18 g of potassium hydroxide solid powder, and activate it at 900° C. for 90 minutes in a nitrogen protective atmosphere to obtain an activated product;

[0066] 3) Wash the activated product obtained in step 2) with 0.5mol / L hydrochloric acid until it is acidic, and stir it magnetically for 2 hours to ensure that it is fully dissolved, then wash and filter until the product is neutral and no chloride ions are detected, then bake at 105°C overnight dry to obtain activated carbon;

[0067] 4) Add 1.5 g of activated carbon and 9 g of p-aminobenzenesulfonic acid obtained in step 3) into 200 ml of deionized water and mix, and place the mixed solution in an oil bath at 45° C. with magnetic force stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com