A kind of composite strip production method and production system

A technology of composite strip and production method, applied in metal rolling and other directions, can solve problems such as inability to carry out mass production, and achieve the effects of good industrial application and promotion value, good surface quality, and wide range of incoming materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

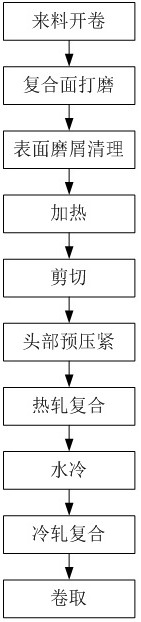

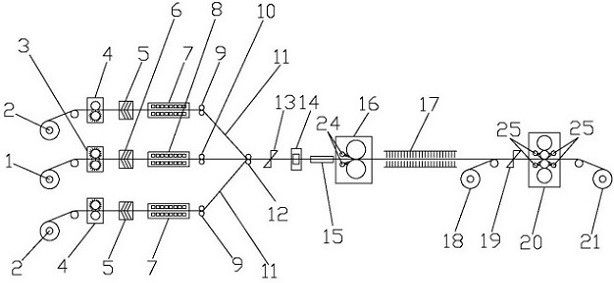

[0039] Such as figure 1 , figure 2 with image 3 As shown, the present embodiment provides a method for producing a composite strip, comprising the steps of:

[0040] (1) Pretreatment of incoming materials

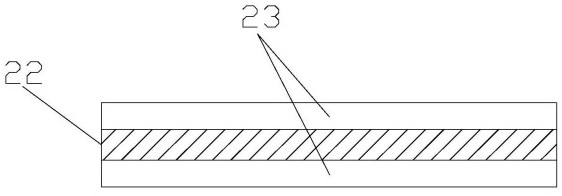

[0041] The base material 22 and the covering material 23 are selected as incoming materials, and the base material 22 and the covering material 23 are respectively subjected to unwinding of the incoming material, grinding of the composite surface, cleaning of the surface wear debris and heating treatment.

[0042] Wherein, the material of base material 22 and cladding material 23 is any one in stainless steel, carbon steel, low-alloy steel, industrial pure titanium, aluminum alloy, and base material 22 and cladding material 23 are fully annealed state; The requirements of the number of layers, wherein the cladding material 23 can be one or more layers, the composite tape produced in the present embodiment is a three-layer composite tape, so the cladding material 23 inclu...

Embodiment 2

[0059] This embodiment takes the production of TA1 titanium / 304 stainless steel / TA1 titanium three-layer composite strip with a thickness of 4mm as an example to further illustrate the production method of the composite strip of the present invention.

[0060] Adopt the production method of the composite strip in Example 1, the base material is 304 stainless steel plate, the base material thickness is 6 mm, the cladding material is TA1 industrial pure titanium plate, the cladding material thickness is 6 mm, both the base material and the cladding material are fully annealed.

[0061] During the heating process, the heating temperature of the 304 stainless steel plate is 950-970°C, and the heating time is 1.5min. The heating temperature of the TA1 industrial pure titanium plate is 490-510°C, and the heating time is 1.5min.

[0062] During the hot rolling composite process, the hot rolling reduction rate is 50%, and the hot rolling rolling speed is 10m / min.

[0063] During the w...

Embodiment 3

[0067] This embodiment takes the production of 5052 aluminum / Q345 steel / 5052 aluminum three-layer composite strip with a finished product thickness of 2mm as an example to further illustrate the production method of the composite strip of the present invention.

[0068] Using the composite strip production method in Example 1, the base material is a Q345 low-alloy steel plate with a thickness of 4 mm, the cladding material is a 5052 aluminum alloy plate, and the cladding material thickness is 3 mm. Both the base material and the cladding material are in a fully annealed state.

[0069] During the heating process, the heating temperature of the Q345 low-alloy steel plate is 850-870°C, and the heating time is 1min. The heating temperature of the 5052 aluminum alloy plate is 420-440°C, and the heating time is 1min.

[0070] During the hot rolling composite process, the hot rolling reduction rate is 40%, and the hot rolling rolling speed is 15m / min.

[0071] During the water cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com